Advanced Space Propulsion System Components

For years, the space industry has trusted Mott products to support advanced space propulsion systems. We provide a comprehensive range of filtration and flow control products essential for propulsion systems for space travel, life support mechanisms, and energy storage systems. Our flow restrictors ensure a laminar flow, crucial for accurate instrumentation readings and optimal satellite thrust. Moreover, our spacecraft propulsion filter products guarantee that propellant or water-cooling systems operate without particle contamination. Our thermal management components, frequently utilized in electronics, are designed for compactness and reduced weight. We utilize a variety of porous media and hardware materials – from Titanium and 316L stainless steel to specialty alloys like Tungsten, Niobium, and Zirconium, as well as polymer and ceramic options – making them perfect for aerospace applications. We also offer custom filtration solutions, including last chance filters, to safeguard critical components.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Satellites & Probes

- Rocket Systems

- Electronics Cooling

- Weapon Systems

- Space Mission Equipment

- Last Chance Filters

Aerospace industry applications

Spacecraft Propulsion Filters for Hazardous Fluids and Gases:

We provide top-tier solutions for filtering fluids and gases that could pose significant risks to the environment or personnel. Our advanced space propulsion systems ensure precision filtration that stands out in the market.

Hydraulic Assemblies for Space Travel:

With decades of expertise, Mott designs and manufactures hydraulic assemblies tailored for various propulsion systems for space travel. Our offerings encompass a range of solutions for hydraulic fluid management, including filters, regulators, and valves.

Loop Heat Pipe (LHP):

LHPs are two-phase heat transfer devices without moving parts. They transport vast amounts of heat over extended distances with exceptional thermal efficiency. Recognizing the significance of advanced thermal management in aerospace, we’ve crafted LHP products to meet these demands.

Last Chance Filters:

Mott’s last chance filters safeguard critical systems by capturing contaminants that might inflict severe damage. With these filters, you can be assured of the protection of your aircraft and advanced space propulsion systems.

Flow Restrictors:

Our flow restrictors meticulously control the fluid flow in aerospace applications, ensuring that vital systems aren’t compromised by excessive fluid flow. Trust Mott Corporation for tailored fluid control devices.

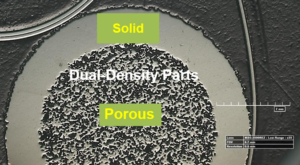

3D Printed Porous Metal Product:

Leading the way in 3D printing technology, Mott Corp crafts porous products suitable for a myriad of aerospace applications. This eliminates the traditional need for welds or fasteners when joining porous metal components.

If you’re in search of solutions for your filtration and fluid management needs in propulsion systems for space travel, contact Mott Corporation.

Propellant Filters for Space

Mott propellant and helium filters protect critical components from motion wear particulate and propellant trace contamination.

Computational Fluid Dynamics Services

Computational Fluid Dynamics (CFD) modeling is an excellent service to accelerate product development. It allows for cost-effective equipment sizing and identification of optimal operational parameters.

Porous Metal for Aerospace

Tech Spotlight of Mott filters and flow restrictors and how they are used in aerospace applications.

Flow Restrictors

Mott works extensively with design engineers across every industry to design and produce customized fluid control devices. Our products replace drilled orifice, capillary tubing and needle valves that wear out over time and provide inconsistent results.

Gas Diffusion Layers

The uniform porosity, strength, and corrosion resistance of Mott's gas diffusion products provide superior performance over other diffusion layer products.

Additive Manufacturing Overview

Our additive manufacturing capabilities provide the most uniform porosity and unique geometries for your application.

FAQs: Advanced Space Propulsion System Components

Q: What are advanced space propulsion systems and how do they differ from traditional propulsion methods?

A: Advanced space propulsion systems refer to innovative technologies designed to propel spacecraft more efficiently and effectively than traditional methods. These systems often utilize cutting-edge materials, designs, and techniques to achieve higher speeds, longer mission durations, and reduced fuel consumption, making space travel more sustainable and cost-effective.

Q: How does Mott Corporation contribute to propulsion systems for space travel?

A: Mott Corporation offers a range of products, from spacecraft propulsion filters to hydraulic assemblies, specifically tailored for propulsion systems for space travel. With decades of experience, Mott designs and manufactures components that ensure precision, safety, and efficiency, meeting the stringent demands of the aerospace industry.

Q: Why is a spacecraft propulsion filter essential in space missions?

A: A spacecraft propulsion filter plays a crucial role in ensuring the purity and efficiency of the propellants used in space missions. By filtering out contaminants and impurities, these filters ensure that propulsion systems operate optimally, reducing risks of malfunctions and enhancing the longevity and reliability of space missions.

Q: How does Mott Corporation’s expertise in 3D printing benefit advanced space propulsion systems?

A: Mott Corporation’s forefront position in 3D printing technology allows for the creation of intricate and customized components that are essential for advanced space propulsion systems. This technology eliminates the need for traditional welds or fasteners, resulting in components that are both lightweight and robust, ideal for the demanding conditions of space travel.

Q: Are Mott’s products suitable for all types of propulsion systems for space travel?

A: Mott Corporation designs and manufactures a broad range of products tailored for various propulsion systems for space travel. From spacecraft propulsion filters to hydraulic assemblies and advanced thermal management solutions, Mott’s products cater to a wide spectrum of aerospace applications, ensuring compatibility, efficiency, and reliability.