Crude & Pure Terephthalic Acid

Mott has been a leader in both crude terephthalic acid (CTA) and purified terephthalic acid (PTA), including pure terephthalic acid (PTA), for decades using both HyPulse® LSI and LSM filter technologies. Mott liquid filters are easily configurable to handle multiple wash and purge steps necessary in CTA and PTA processes to ensure product quality. Our filters reduce caustic acid consumption in the CRU, minimize organic loads in wastewater treatment, and can recover up to 2 wt.% solids from CTA, PTA, or pure terephthalic acid (PTA) applications. For applications designed around corrosion metal control, the Mott LSI can act as an intermediate filter, removing precipitated corrosion metals before downstream processing. The average return on investment for a Mott LSI filter in a CTA, PTA, or pure terephthalic acid (PTA) application is only two years.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- PTA Manufacturing

- CTA Manufacturing

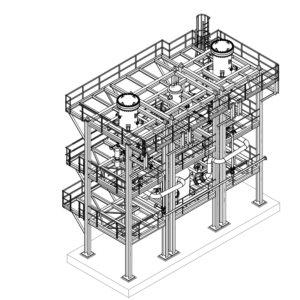

Process Systems overview

A comprehensive overview of Mott's offerings for process filtration applications.

Elements

Explore the features and benefits of Mott sintered porous metal media for superb filtration efficiency, structural integrity and uniform porosity.

Mott Design Process

We take a scientific approach to filtration system design to not only ensure your project stays on time and on budget, but also to ensure it operates at peak efficiency.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Understanding Pure Terephthalic Acid (PTA) in Mott's Solutions

Pure terephthalic acid (PTA) is a crucial component in the production of polyester and PET resin, used in various industries. Mott’s expertise in both crude terephthalic acid (CTA) and purified terephthalic acid (PTA) processes, including pure terephthalic acid (PTA), spans decades, with a focus on enhancing efficiency and product quality. Our liquid filters, equipped to handle multiple steps in CTA and PTA production, help reduce caustic acid consumption, minimize organic waste in wastewater treatment, and recover valuable solids, ensuring top-notch PTA quality. Whether you’re new to the world of pure terephthalic acid (PTA) or seeking ways to optimize its production, Mott’s solutions offer the reliability and performance needed in this critical industry.

FAQs: Pure terephthalic acid

Q: What is pure terephthalic acid (PTA)?

A: Pure terephthalic acid (PTA) is a vital chemical compound used in the production of polyester and PET resin. It serves as a key building block for various products, including fibers, films, and packaging materials.

Q: How is pure terephthalic acid (PTA) produced?

A: PTA is typically produced through the oxidation of p-xylene, a petroleum-derived compound. The process involves several chemical reactions and purification steps to obtain high-purity PTA suitable for a wide range of applications.

Q: What are the applications of pure terephthalic acid (PTA)?

A: Pure terephthalic acid (PTA) is primarily used in the manufacture of polyester fibers and PET resin, which find extensive use in textiles, bottles, packaging materials, and more. It is a fundamental component in the production of various everyday products.

Q: How can Mott’s solutions benefit pure terephthalic acid (PTA) production?

A: Mott offers specialized filtration solutions that enhance the efficiency and quality of pure terephthalic acid (PTA) production processes. Our liquid filters reduce caustic acid consumption, minimize organic waste in wastewater treatment, and recover valuable solids, contributing to improved PTA production and sustainability.