Ultra High Purity Porous Ceramics

Mott’s high purity ceramic technology, utilizing ultra high purity porous ceramics, can be tailored to meet unique application requirements. This ceramic technology provides a broad spectrum of chemical compatibilities and robustness in high temperature and pressure scenarios. High purity porous ceramics, especially porous alumina (or aluminum oxide Al2O3), are recognized for their mechanical strength, wear resistance, and resilience in corrosive settings.

These ceramics have a maximum operating temperature of 2,750 degrees Fahrenheit and can withstand pressures up to 5,000 psi. Their geometric flexibility allows them to be crafted into various forms, from small tubes or bushings to discs, plates, or even electrostatic chucks. The durability and adaptability of porous ceramics enable a plethora of applications across diverse sectors.

Manufacturing these ceramics in a Class 100 clean room environment with >99.5% pure alumina ensures unparalleled cleanliness. The inherent properties of high purity alumina materials, such as high temperature stability, impressive hardness, corrosion resistance, minimal thermal expansion, and a high melting point, make them ideal for components in CVD processes, ion implants, and other semiconductor processes.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Electrostatic Chuck Conduits and Feed Systems

- Ultra High Purity Gas Diffusion

- High Temperature Liquid Filtration

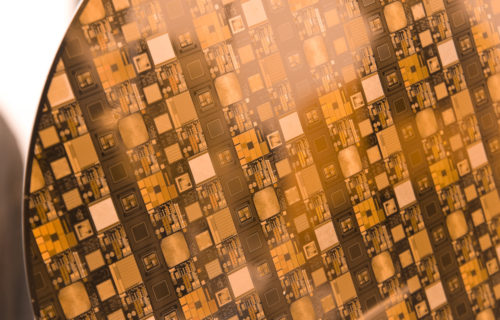

- Semiconductor Wafer Fabrication Components

- CVD Equipment Parts

- Electronic Components and Substrates

- Gas Flow Plugs and Ports

Semiconductor Products Catalog

Explore Mott’s wide range of high purity filters, diffusers and flow restrictors designed exclusively for semiconductor manufacturers.

Product Specs

| Operating Conditions |

» Maximum Operating Pressure: 5,000 psi » Maximum Operating Temperature: 2,750°F (1,500°C) » Maximum Differential Pressure: 1,250 psi |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Specifications |

|

||||||||||

| Geometries |

Small Tubes/Bushings Plates Discs

|

Videos & Articles

Our Design Capabilities

- Flow/pressure drop curves and filtration efficiency for virtually any design

- Gas compatibility considerations

- Custom filter media, pressure vessel, and fitting material and configurations available

Relevant Services for Porous Ceramics and High Purity Ceramic Solutions

Design Expertise – From conceptualization to completion, we customize high purity ceramic solutions based on your design parameters. Embracing challenges, our dedicated team is committed to crafting the best porous ceramics without compromising on quality, no matter the complexity of the task.

Lab Testing – Should you require data packages or feasibility testing for your porous ceramic components before installation, we’re at your service. Our lab center conducts comprehensive characterization and performance tests, ensuring your parts meet stringent specifications. This rigorous testing elucidates the precise capabilities and potential limitations of the products, preventing costly damages from overexertion or undue stress.

Engineering Support – Engage with our project engineers to delve deep into your process requirements and choose the right porous ceramic or electrostatic chuck design tailored to your application. With a myriad of customization options for our ceramic products, our expert engineers are dedicated to ensuring that what you receive is perfectly aligned with your specific needs.

Top Tier Products

At Mott, we are proud to supply high-quality products that have been implemented across several industries for decades. Our high purity porous ceramics are rated highly in several areas, ensuring they will stand up to the demands that your machinery requires. We also can develop additional geometries of our ultra high purity porous ceramics. Mott sales representatives are happy to have a conservation with you to determine if our capabilities align with your needs!

FAQs: Ultra High Purity Porous Ceramics

Q: What are the unique features of Mott’s ultra high purity porous ceramics?

A: Mott’s ultra-high purity porous ceramics are customizable to specific application requirements. They offer a wide range of chemical compatibilities and are durable in high temperature, high voltage, and/or high pressure environments. These ceramics are especially suitable for applications requiring the highest purity standards.

Q: To what level do Mott’s high purity ceramic products handle extreme temperatures and pressures?

A: Mott’s high purity porous ceramics can operate at temperatures up to 2,750 degrees Fahrenheit and withstand pressures of up to 5,000 psi. This makes them ideal for demanding applications that require resilience to extreme conditions.

Q: In what forms can Mott’s porous ceramics be manufactured?

A: Mott’s porous ceramics exhibit high geometric flexibility. They can be crafted into various shapes such as small tubes, bushings, discs, or showerhead plates, catering to diverse application needs. Mott is currently developing 3D printing of ceramic parts to fabricate complex geometries to include precise porosity where needed.

Q: What are the primary benefits of using porous alumina in high purity ceramic applications?

A: Porous alumina, or aluminum oxide Al2O3, offers outstanding mechanical strength, wear resistance, and resistance to corrosive environments. Its high stability at elevated temperatures, impressive hardness, excellent corrosion resistance, low thermal expansion coefficient, and high melting point make it valuable across many industries, especially in semiconductor processes.

Q: Can Mott’s porous ceramics be used in electrostatic chuck applications?

A: Mott can provide critical components of an electrostatic chuck to extend its useful life and improve its thermal management performance. For example, our advanced porous ceramic plugs are crafted from high purity alumina with meticulously engineered pore sizes, enabling reliable and uniform cooling gas flow. Their inherent high voltage breakdown strength allows them to operate for extended periods without arcing events, thereby enhancing the productivity of the overall semiconductor tool. With this reduced risk of arcing events that typically cause yield-limiting debris combined with a more uniform backside cooling, you can now maximize the performance of your process chamber through enhanced process control and more predictable maintenance schedules.

Q: What makes porous alumina a preferred material for high purity ceramic applications?

A: Porous alumina, also known as aluminum oxide (Al2O3), is a ceramic material renowned for its exceptional mechanical strength, wear resistance, and resilience in corrosive environments. Its properties, such as high temperature stability, hardness, corrosion resistance, low thermal expansion coefficient, and a high melting point, make it invaluable for various industries. Mott’s high purity porous alumina ceramics are manufactured with over 99.5% pure alumina, ensuring optimal performance and purity for critical applications.