Filtration Skids

Mott Corporation supplies fully integrated filter skid designs for all major process filtration technologies, including advanced filtration skids for hydrogen production. Through our graded approach to design, a wide partner network, and excellent project management, we deliver complete filtration skids in months, not years. Our filtration skids are designed with modular concepts, allowing us to efficiently integrate customer-specific preferences on piping, valves, instrumentation, controls and programming, and other supporting equipment. By choosing Mott for your complete filtration project, including design and implementation of filtration skids, you reduce your risk and time investment. Our expertise ensures that your filtration system is optimized for performance, reliability, and compliance with industry standards.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- FCC/RFCC Refining

- Petrochemicals (ex. Needle Coke)

- Hydrogen Production Balance of Plant

- High temperature or corrosive chemical processing

- Ultra-pure chemicals requiring sub-micron filtration

- Hot gas processes (ex. Waste to energy plants)

Process Filtration Overview

A comprehensive overview of Mott's offerings for fully automatic filtration systems and applications.

Filter Elements Overview

Explore our filter elements in a wide range of materials and sizes, and with a selection of fittings – and know we also create original designs for specialized needs.

Catalyst Filtration

Catalyst Recovery Filtration Application Brief and Installation Examples. LSI, LSM, LSX Filters

Filter Feasibility Testing

Filter feasibility testing and application analysis for liquid and gas filtration processes.

Lab and Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

FCC/RFCC Filtration Application Brief

Overview of Mott capabilities and install base for FCC/RFCC Slurry Filtration

Product Specs

| Customization |

Mott Turnkey Filter Skids are customized to the specification and footprint of your process. Consult with an engineer for a detailed design review. |

|---|

Videos & Articles

Design Capabilities

Process Design – The Mott engineering team has the capability to perform all process design, vessel design, generate PFDs and P&IDs, and specify valves, instruments, and other supporting critical equipment for filtration skids. Our comprehensive approach ensures that each filtration skid is optimized for specific process requirements, offering seamless integration and superior performance.

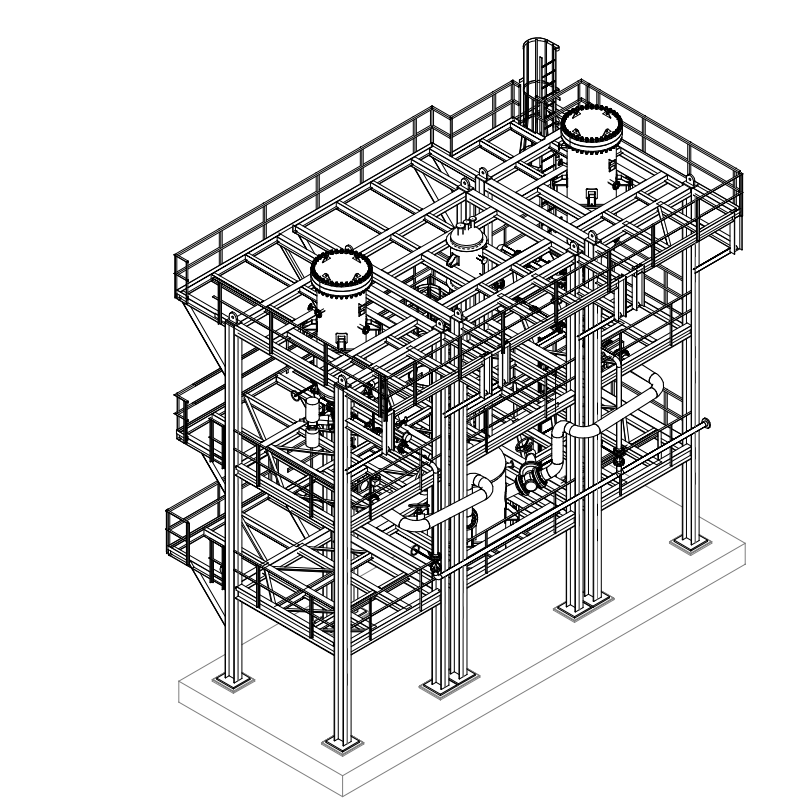

Design Modeling – Mott can perform detailed 3D modeling of filtration skids and sub-components, often using this integrated 3D model as a training tool for customer maintenance personnel. This detailed visualization aids in the understanding of system operation and maintenance procedures.

Piping and Structural Analyses – Mott can provide all required piping, pipe support, and structural qualification calculations for filtration skids based on our own internal standards, customer requirements, or internationally recognized codes and standards. This ensures that our filtration skids meet the highest levels of safety and reliability.

Detailed Fabrication Drawings – The Mott team can generate all required piping isometrics, pipe spool drawings, and required structural detail drawings to be used to fabricate the filtration skid and critical components. These comprehensive drawings ensure accuracy and efficiency during the fabrication process.

Relevant Services

Filter Feasibility Testing – Want a recommendation on the correct filter media, alloy, and backwash frequency for your filtration skid process? Coordinate with a Mott representative to send a sample of your feedstock to our lab to determine the correct filtration design for your process.

Front End Engineering Design (FEED) Packages – Prior to beginning fabrication, Mott can perform FEED phase work consisting of necessary process and structural designs of the filtration skid system. This work also includes identifying the total valve and instrument count and developing the functional specification of the filtration skid. A FEED phase ensures an accurate final cost estimate and project schedule, generally culminating with an onsite detailed design review.

Programming and Implementation – Mott filtration skids are fully automated, hands-off equipment. We can provide detailed programming and the implementation of that programming into Mott supplied or customer-supplied hardware. Mott’s filtration skids are flexible such that programming can be either a local PLC to control just the filtration skid or can be integrated directly into the plant DCS system to be controlled and monitored from the comfort of a control room.

On-Site Field Services – Mott’s services don’t stop at design work. Our Field Engineering team will be at your site for commissioning, startup, and post-startup support to ensure the successful operation of the filtration skid system.

Post-Install Data Analysis/Preventative Maintenance – The Mott team can analyze filter performance data trends to confirm successful operation of the filtration skid, recommend operational changes based on feedstock or plant changes, and in many cases recommend maintenance or offline filter element cleaning schedules.

Advanced Filtration Skids by Mott

Mott’s filtration skids are engineered solutions designed to meet the rigorous demands of industrial processing, offering a compact, efficient, and reliable method for filtering particulates and contaminants from liquids and gases. These skids combine state-of-the-art filter elements with vessels, piping, valves, and instrumentation, creating a fully integrated system ready for immediate deployment in a wide range of applications. Ideal for sectors such as hydrogen production, pharmaceuticals, chemicals, food and beverage, and oil and gas, our filtration skids are customizable to specific process requirements, ensuring optimal performance and protection of critical process equipment. With Mott’s expertise in filtration technology, these skids provide a high-performance solution that enhances process efficiency and product quality.

FAQs: Filtration Skids

Q: What are filtration skids?

A: Filtration skids are modular systems that integrate all the necessary components for efficient filtration in a compact unit. These systems typically include filter elements, vessels, pumps, piping, valves, and control instrumentation. Designed for ease of installation and operation, filtration skids are used across various industries to remove contaminants from liquids and gases, ensuring process integrity and product quality.

Q: How do filtration skids benefit industrial processes?

A: Filtration skids offer numerous benefits, including improved process efficiency, enhanced product quality, and protection of downstream equipment. Their compact, modular design allows for easy integration into existing processes, quick installation, and minimal footprint. Additionally, pre-engineered skids ensure reliable performance and reduce the time and cost associated with custom field installations.

Q: Can filtration skids be customized for specific applications?

A: Yes, filtration skids can be fully customized to meet the unique requirements of different applications. Factors such as flow rate, filtration efficiency, material compatibility, and operating conditions are considered to design a skid that optimally addresses the specific filtration needs of a process.

Q: What industries commonly use filtration skids?

A: Filtration skids are widely used in industries such as hydrogen production balance of plant, pharmaceuticals, food and beverage, chemical processing, oil and gas, and water treatment. They are versatile and can be designed to handle a variety of fluids, including corrosive chemicals, high-purity water, and process gases.

Q: How are filtration skids maintained?

A: Maintenance of filtration skids involves routine checks and cleaning of filter elements, valves, pumps, and instrumentation to ensure optimal performance. Many skids are designed for easy access to components for quick replacement or cleaning. The specific maintenance schedule and procedures depend on the type of filtration system, the nature of the filtered media, and the operating conditions.

Q: What should be considered when selecting a filtration skid?

A: When selecting a filtration skid, consider factors such as the type and size of particles to be removed, the chemical compatibility of materials with the process fluid, the desired flow rate, pressure drop limitations, and environmental operating conditions. It’s also important to work with a supplier like Mott, who can provide expert advice and customization options to meet your specific filtration requirements.