Hydrotreating

Hydrotreating is a crucial process performed in an oil refinery to produce high-quality fuels and feedstocks. It involves reducing sulfur or nitrogen content, saturating olefins for stability improvement, or reducing aromatic content. During hydrotreating, refineries use Mott filters to filter the hydrotreater feed to prevent plugging and fouling of the catalyst fixed bed. These filters are also vital for filtering hydrotreater product to capture catalyst fines that may escape from the fixed bed. Aggressive hydrotreating of residual fuel oil in an ebullated-bed hydrotreater/hydrocracker, especially for removing sulfur to meet the 2020 marine bunker fuel 0.5% sulfur limit, necessitates the use of a Mott filter. This filter effectively processes hydrotreater product, recycles any catalyst that escapes from the ebullated bed, and ensures the integrity and efficiency of the hydrotreating process.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Hydrotreating Processes

Process Systems Overview

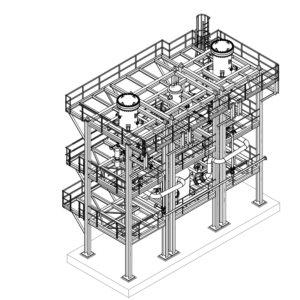

Mott filter systems are designed for maximum process results, extended service life, and a rapid return on investment. We provide complete filter systems modularized to include all valves, instruments, controls, piping and gauges.

Hydrotreating Application Brief

Use Mott HyPulse® filter technology to protect expensive catalyst beds without having to take the filter offline for cleaning.

Elements

Explore the features and benefits of Mott sintered porous metal media for superb filtration efficiency, structural integrity and uniform porosity.

Mott Design Process

We take a scientific approach to filtration system design to not only ensure your project stays on time and on budget, but also to ensure it operates at peak efficiency.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Enhancing Hydrotreating Efficiency with Mott's Advanced Filtration

Hydrotreating is an essential process in oil refineries, where Mott’s advanced filtration technology plays a critical role. In hydrotreating, Mott filters are used to purify feedstocks by removing impurities, which is crucial for preventing the plugging and fouling of the catalyst bed. This not only ensures the production of high-quality fuels but also maintains the operational efficiency and longevity of hydrotreating units. Mott’s filtration solutions are specially designed to handle the rigorous demands of hydrotreating processes, capturing fine catalyst particles and safeguarding against contamination, thereby optimizing the overall refining operation.

FAQs: Hydrotreating

Q: What is hydrotreating in the context of oil refining?

A: Hydrotreating is a refining process used to remove impurities like sulfur, nitrogen, and metals from petroleum products. This process is crucial for producing cleaner, higher-quality fuels and for meeting environmental standards. Hydrotreating involves passing hydrocarbon feedstock over a catalyst under high pressure and temperature, which facilitates the removal of impurities.

Q: How do Mott’s filters enhance the hydrotreating process?

A: Mott’s filters enhance the hydrotreating process by efficiently filtering out impurities from the feedstock before it enters the hydrotreater. This pre-filtration step helps in preventing the fouling and plugging of the catalyst bed, ensuring smooth operation and extending the life of the catalyst. Additionally, Mott’s filters are used to capture fine catalyst particles in the hydrotreater product, ensuring the quality and purity of the final output.

Q: Why is filtration important in hydrotreating?

A: Filtration is important in hydrotreating to protect the catalyst bed from contaminants that could reduce its effectiveness and lifespan. Proper filtration ensures consistent processing and quality of the refined products. It also plays a vital role in meeting stringent environmental regulations by removing harmful impurities from fuel.

Q: Can Mott’s filtration systems be customized for specific hydrotreating applications?

A: Yes, Mott’s filtration systems can be customized to meet the specific requirements of different hydrotreating applications. Factors like the type of feedstock, flow rate, pressure, and temperature conditions are taken into account to design filters that provide optimal performance and durability in the specific conditions of a refinery’s hydrotreating unit.