4th Stage Separators

Mott GSV (Gas Solids Venturi) filters, often positioned as 4th stage separators, are utilized to recover and transfer catalyst fines to a storage hopper and to ensure particulate emissions are minimized. This not only protects downstream equipment but also limits the amount of emissions released into the environment. When particulates are allowed to remain in the gas stream, they can cause fouling, plugging, and erosion of downstream equipment, including the turboexpander, waste heat boiler, and related components, necessitating offline service and resulting in costly process disruptions. When installed on the underflow stream from the third stage separator, a sintered metal filter, acting as an effective 4th stage separator, substantially reduces the loss of expensive catalyst and often provides a payback period of less than one year.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Recovery and Transport of Cat Fines to Hopper Vents

GSV Filters

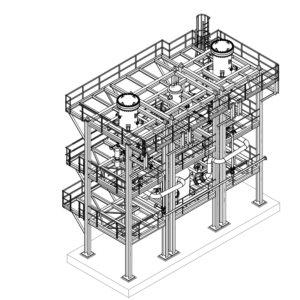

GSV Filter Systems - Gas Solids Venturi Pulse Blowback

Mott Design Process

Our Five-step design process will ensure you receive the right filtration unit for your capital investment.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Understanding 4th Stage Separators in Industrial Filtration

Mott’s 4th stage separators are pivotal components in industrial filtration, offering advanced purification in processes where minute particulate matter needs to be removed from gas streams. These separators, renowned for their efficiency, are critical in protecting sensitive downstream equipment from damage due to fine particles. Employing sintered metal filters, Mott’s 4th stage separators excel in trapping even the most diminutive particulates that evade earlier stages, ensuring the highest level of purity and operational efficiency. This makes them an indispensable tool in industries requiring stringent gas purity standards, such as petrochemical and natural gas processing.

FAQs: 4th Stage Separators

Q: What is the role of Mott Corp’s 4th stage separators in industrial processes?

A: Mott Corp’s 4th stage separators are essential for achieving the highest level of particulate removal in various industrial gas streams. These separators are used as a final filtration stage, effectively capturing the finest particles that earlier stages cannot. This results in superior protection for downstream equipment and ensures the highest purity in the final output, making them ideal for critical applications in industries like petrochemicals and gas processing.

Q: How do Mott Corp’s 4th stage separators enhance operational efficiency?

A: By integrating Mott Corp’s 4th stage separators into industrial processes, companies can significantly reduce maintenance downtime and costs. These separators prevent fouling, plugging, and erosion of sensitive downstream equipment, such as turboexpanders and heat exchangers. Their high efficiency in capturing fine particulates also means less frequent filter replacements and a more streamlined operation.

Q: Are Mott Corp’s 4th stage separators customizable for specific industrial needs?

A: Yes, Mott Corp offers customization for their 4th stage separators to suit specific industrial requirements. Understanding that different processes have unique demands, Mott Corp designs these separators to cater to varying particulate sizes, gas compositions, and flow rates, ensuring optimal performance in each unique application.

Q: What makes Mott Corp’s 4th stage separators different from standard separators?

A: Mott Corp’s 4th stage separators stand out due to their advanced filtration technology, particularly the use of sintered metal filters. These filters are capable of capturing extremely fine particles, far beyond the capability of standard separators. This high level of filtration is crucial in industries where even the smallest particulate matter can have significant impacts on product quality and process efficiency.