Porous Metal Sheet Manufacturer

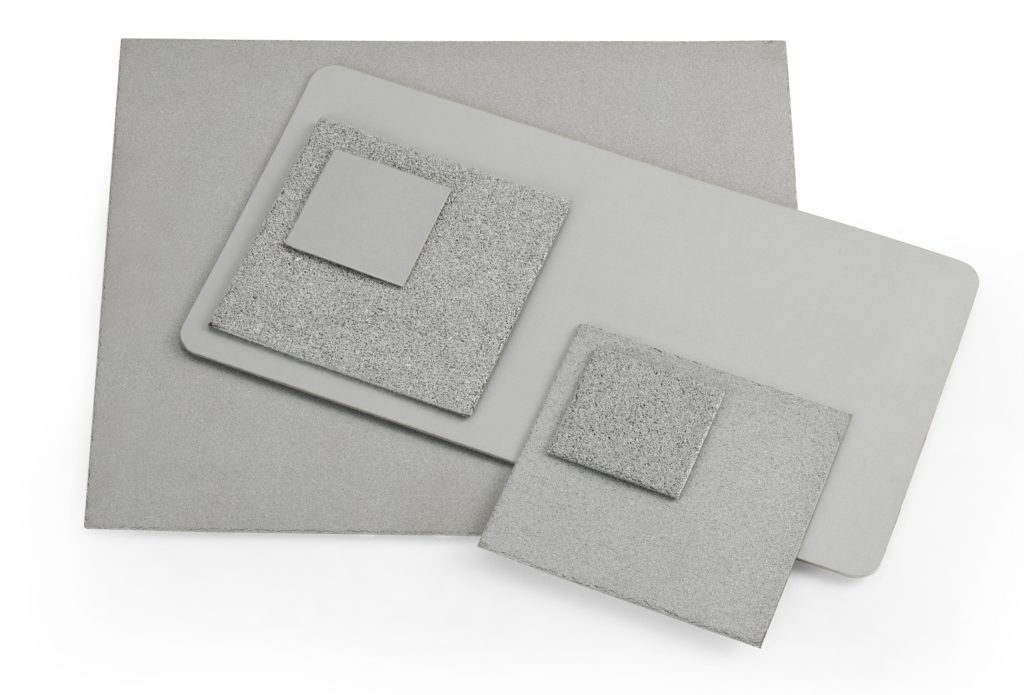

Mott specializes in customizing porous metal sheet tailored to your application and specifications. Leveraging proprietary manufacturing techniques, we produce the industry’s thinnest porous metal sheet, with dimensions as thin as .007”. We can adjust parameters like length, width, thickness, alloys, and media grades of the porous metal sheet to address diverse filtration, flow, and chemical compatibility requirements for your product or process.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Fuel Cells

- Gas Generation

- Gas Storage

- Various filtration

- Various flow control

Porous Metal Overview

Check out the features and benefits of Mott sintered porous metal media that delivers uniform porosity for superb filtration efficiency and structural integrity.

Lab and Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott’s Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Porous Metal Cleaning Guide

Porous metal cleaning techniques

Product Specs

| Length |

Common Lengths – 10″, 12″, 24″, 40″ Sheet can be laser cut or sheered into smaller sizes if required. Please consult factory for customization. |

|---|---|

| Width |

Common Widths – Less than 10” Sheet can be laser cut or sheered into smaller sizes if required. If you need a custom width, please consult factory. |

| Thickness |

Common Thicknesses – .039″-.125” (dependent on media grade) Custom thicknesses available, consult factory |

| Media Grades |

Common Media Grades – 0.2, 0.5, 2, 5, 10, 20, 40, 100 Custom media grades available upon request, consult factory |

| Materials |

Common alloys – 316LSS, Titanium, Nickel 200, Hastelloy® C-276, Inconel® 600 Custom alloys available upon request, consult factory |

| Operating Temperatures |

Alloys with temperature resistance up to 1700° degrees Fahrenheit are available. Custom alloys available to accommodate unique operating temperatures, consult factory |

Videos & Articles

Our Design Capabilities for Porous Metal Sheet

Application Engineering – Need consultation on your porous metal sheet design? Our team of application engineers is on standby to guide you in selecting the right porous metal sheet for your requirements. With decades of experience collaborating with the world’s leading technical and performance brands, we specialize in crafting the ideal porous metal sheet to address intricate challenges.

Customer Innovation Center – We take pride in partnering with customers on intricate porous metal sheet projects. To this end, we’ve established a dedicated facility. Interested in hands-on lab testing and engineering consultation for your porous metal sheet needs? Join us at our Customer Innovation Center in Connecticut to craft a solution tailored to your specific application.

Rapid Prototyping Cell – Need to assess the viability of your porous metal sheet design swiftly? Our rapid prototyping cell can produce porous metal sheet prototypes in as little as 2 weeks. Our engineers utilize equipment mirroring our main manufacturing setup, ensuring your porous metal sheet design is both manufacturable and cost-effective.

Relevant Services for Porous Metal Sheet

Lab Testing – If you require data packages or feasibility testing for your porous metal sheet before installation, we’re here to assist. At our lab center, we conduct various characterization and performance tests to ensure your porous metal sheet meet stringent specifications before they reach you.

Computational Fluid Dynamics – Interested in modeling how your process fluids interact with a Mott porous metal sheet? Speak with your Mott representative about how we can utilize CFD software to provide insights specific to porous metal sheets.

Engineering Memberships – For those consistently tackling intricate designs of porous metal sheet that demand the pinnacle of engineering support, inquire about our membership rates. These memberships offer discounted access to a range of services, including lab testing, prototyping, and other vital engineering resources tailored for porous metal sheet development.

Mott's Superior Porous Metal Sheet

Porous metal sheet are specialized metal components characterized by a network of interconnected pores, allowing for controlled fluid or gas flow while simultaneously filtering out contaminants. These sheet are invaluable in industries such as chemical processing, pharmaceuticals, and aerospace, where precise filtration and flow control is paramount. The unique structure of porous metal sheet ensures efficient separation and optimal performance in various challenging environments. Mott stands out in the provision of porous metal sheet due to its cutting-edge engineering techniques, proprietary materials, and a legacy of industry expertise. With a steadfast commitment to innovation and quality, Mott’s porous metal sheet consistently set the industry benchmark, delivering unparalleled performance and reliability.

FAQs: Porous Metal Sheet

Q: What is a porous metal sheet?

A: A porous metal sheet is a specialized metal component with a network of interconnected pores. It allows for controlled fluid or gas flow while effectively filtering out contaminants, making it ideal for various industrial applications.

Q: How are Mott’s porous metal sheet different from others in the market?

A: Mott’s porous metal sheet are crafted using advanced engineering techniques, proprietary materials, and decades of industry experience. This ensures superior filtration, durability, and efficiency, setting them apart from standard offerings in the market.

Q: What are the common applications of Mott’s porous metal sheet?

A: Mott’s porous metal sheet find applications in a wide range of industries, including chemical processing, pharmaceuticals, aerospace, and more. They are essential in scenarios that demand precise filtration and efficient separation.

Q: Can I customize the specifications of a porous metal sheet from Mott?

A: Absolutely! Mott Corporation prides itself on its ability to work closely with clients to design and manufacture custom porous metal sheets tailored to specific applications and operational conditions. Their engineering team collaborates with customers to ensure every sheet meets the desired specifications.

Q: How do I maintain and clean a Mott porous metal sheet?

A: Mott designs its porous metal sheet for easy maintenance. Depending on the type of contaminants and the sheet material, they can be cleaned using methods like backflushing, ultrasonic cleaning, or specific chemical treatments. Regular maintenance ensures optimal performance and extends the sheet’s lifespan.