FCC/RFCC Slurry

Mott LSI filters excel in removing alumina-silica catalysts and other solids from FCC/RFCC main column bottom slurry feeds. Featuring online, clean-in-place backwashing and automated process control, these filters consistently achieve less than 100 ppm total suspended solids in filtrate quality. This ensures the filtered oil is ideal for blending or as a sellable product. The flexibility of Mott’s system allows backwashed slurry to be recycled to the riser, concentrated, or disposed of as per refinery needs. With installations in over 20 filters across five continents in both FCC and RFCC slurry oil applications, Mott LSI filters are a proven solution in the refining industry.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- MCB Feed

- Carbon Black Production

- Needle Coke Production

- Bunker Fuel

- Marine Fuel

- Hydrotreater Feed

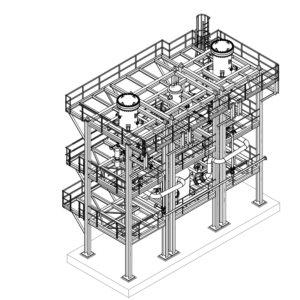

Process Systems Overview

Mott filter systems are designed for maximum process results, extended service life, and a rapid return on investment. We provide complete filter systems modularized to include all valves, instruments, controls, piping and gauges.

Filter Elements Overview

Explore our standard filter elements in a wide range of materials and sizes, and with a selection of fittings – and know we also create original designs for specialized needs.

Mott Design Process

We take a scientific approach to filtration system design to not only ensure your project stays on time and on budget, but also to ensure it operates at peak efficiency.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

What are FCC slurry oil filters?

FCC slurry oil filters, a key product in Mott’s lineup, are essential in refining operations for filtering Fluid Catalytic Cracking (FCC) slurry oil. These filters are designed to remove fine particulates, including alumina-silica catalysts, from the slurry oil that is produced during the FCC process. Mott’s advanced FCC slurry oil filters stand out for their efficiency, achieving filtrate quality with less than 100 ppm of total suspended solids. This ensures that the filtered oil meets the high standards required for blending or sale, making these filters a critical component in optimizing refinery output and profitability.