Food Processing Filters

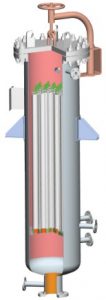

Mott offers superior food processing filters and spargers, specifically designed for demanding high-temperature, corrosive processes used in the production of hydrogenated oils. Our advanced porous metal elements excel in sub-micron filtration, capturing catalysts like nickel and palladium with an impressive 99.9% efficiency. Moreover, our solutions provide a rapid return on investment, typically in less than a year. In addition to filtration, our porous metal spargers are employed for precise pH control in these critical processes.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Hydrogenated Oils

- Catalyst Filtration

LSI Filters

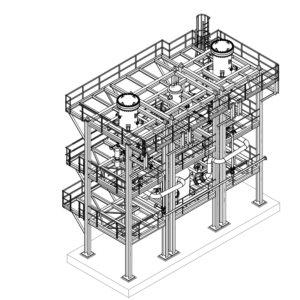

Mott’s HyPulse® LSI porous metal filter elements offer the ultimate in particle retention, backwashability, and durability.

Sparging Overview

Mott spargers introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and numerous than other sparging methods. The result is greater mass transfer, which reduces the time and volume required to dissolve gas into liquid.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Catalyst Recovery Filtration

HyPulse® liquid filters from Mott excel at capturing or recycling expensive catalyst to help manufacturers achieve significant cost savings.

Advanced Filtration Solutions for Food Processing

Food processing filters are specialized components used in the food and beverage industry to ensure the quality and safety of food products. These filters are crucial for removing impurities, contaminants, and unwanted particles from liquids and gases involved in various food manufacturing processes. They play a vital role in maintaining product consistency, complying with regulatory standards, and safeguarding consumer health.

Mott stands out as a trusted provider of food processing filters due to its advanced porous metal technology and unmatched expertise. Mott’s filters offer sub-micron level filtration, ensuring the removal of even the tiniest particles and contaminants. Their filters are designed to meet the stringent hygiene and quality requirements of the food industry, making them a top choice for manufacturers looking to enhance product quality and safety. With a history of excellence and innovation, Mott continues to provide the best filtration solutions for food processing applications.

FAQs: Food Processing Filters

Q: What types of food processing filters does Mott offer?

A: Mott offers a range of food-grade filters designed for various applications in the food processing industry, including particulate filtration, catalyst capture, and pH control.

Q: How do Mott’s food processing filters improve product quality?

A: Our food processing filters ensure the removal of contaminants and impurities, enhancing product quality, flavor, and safety. They help maintain consistent product characteristics and reduce the risk of defects.

Q: Are Mott’s food processing filters compliant with food safety regulations?

A: Yes, Mott’s food processing filters are designed to meet stringent food safety regulations and industry standards. They are made from materials that are safe for contact with food products.

Q: Can Mott’s filters be customized for specific food processing applications?

A: Yes, Mott offers customizable filtration solutions tailored to the unique needs of different food processing processes. Our engineering team can work with you to design filters that meet your specific requirements.

Q: What benefits can I expect from using Mott’s food processing filters?

A: By using Mott’s food processing filters, you can achieve improved product quality, reduced production costs, increased efficiency, and compliance with food safety standards, ultimately leading to higher customer satisfaction and profitability.