Needle Coke

Needle coke, essential for manufacturing graphite electrodes for steel and aluminum production furnaces, requires a high purity level. Utilizing a Mott filter to purify the needle coke production feedstock is critical. This process removes contaminants, ensuring the production of high-quality needle coke. Such refinement is crucial for the electrodes’ performance in furnaces, highlighting the significance of using advanced filtration techniques in the production chain. This step ensures the electrodes produced can meet the demanding conditions of steel and aluminum manufacturing, emphasizing the role of needle coke in industrial applications.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Application:

- Needle Coke Production

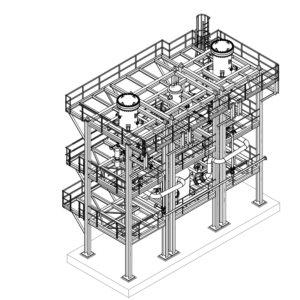

Process Systems Overview

A comprehensive overview of Mott's offerings for process filtration applications.

Porous Metal Elements Overview

Explore the features and benefits of Mott sintered porous metal media for superb filtration efficiency, structural integrity and uniform porosity.

Mott Design Process

We take a scientific approach to filtration system design to not only ensure your project stays on time and on budget, but also to ensure it operates at peak efficiency.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Filter Feasibility Testing

Filter feasibility testing and application analysis for liquid and gas filtration processes.

What are graphite electrodes and needle coke?

Graphite electrodes are conductive rods used in electric arc furnaces for the production of steel and other metals. They are made by processing needle coke, a high-quality type of petroleum or coal-based coke, into a dense and electrically conductive material. Needle coke, due to its unique structure and high purity, is the preferred raw material for producing these electrodes, ensuring they have the necessary conductivity and durability for the high-temperature smelting process.

Why Choose Mott Corp for Needle Coke Filtration

Graphite electrodes are conductive rods used in electric arc furnaces for the production of steel and other metals. They are made by processing needle coke, a high-quality type of petroleum or coal-based coke, into a dense and electrically conductive material. Needle coke, due to its unique structure and high purity, is the preferred raw material for producing these electrodes, ensuring they have the necessary conductivity and durability for the high-temperature smelting process.

FAQs: Needle Coke

Q: What is the primary application of needle coke?

A: Needle coke is primarily used to produce graphite electrodes, which are consumed in steel and aluminum production furnaces.

Q: How do Mott filter systems enhance the quality of needle coke production?

A: Mott filter systems, specifically designed for needle coke production, filter slurry oil to meet feedstock requirements. This ensures the consistent production of a high-quality needle coke product.

Q: Why is filtration crucial in the production of needle coke?

A: Filtration is essential in needle coke production to eliminate contaminants from the feedstock, ensuring the consistent and high-quality output of the needle coke product.

Q: How do Mott’s filtration skids contribute to the needle coke production process?

A: Mott’s filtration skids are designed to offer superb filtration efficiency, ensuring that contaminants are effectively removed from the needle coke production feedstock. This results in a consistent and high-quality needle coke product.