Manufacturing Material Handling

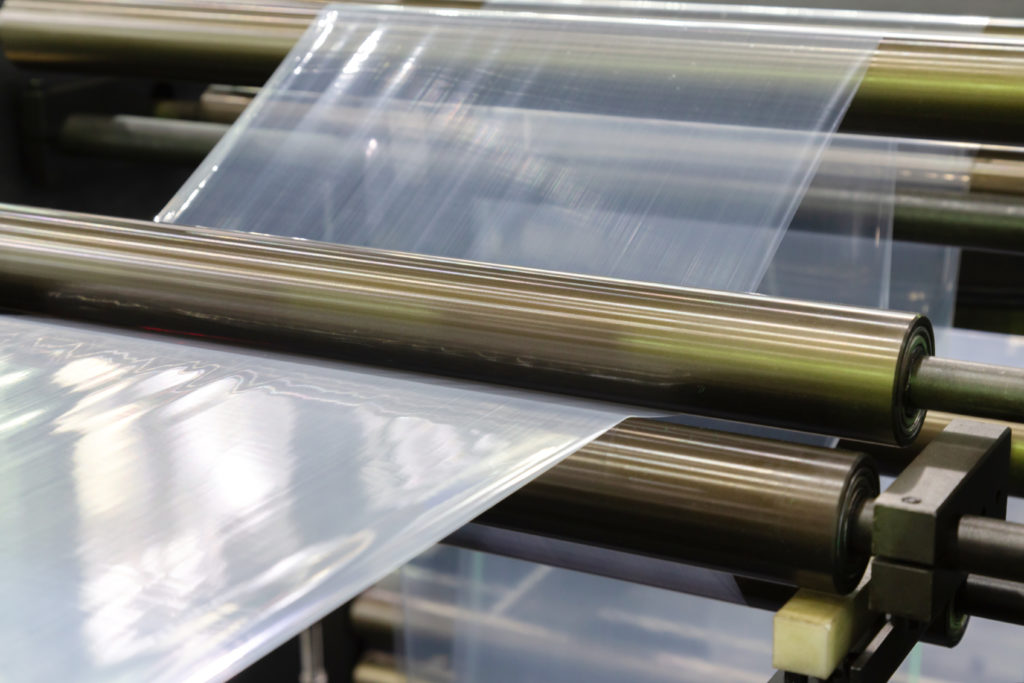

Porous designs are integral to efficient manufacturing material handling, enabling the smooth transport of sensitive materials for high yield production processes. In the realm of manufacturing material handling, as processes become increasingly automated or reach high volumes, the need to transport sensitive materials safely throughout the production process becomes paramount. Mott’s solutions, designed to mitigate small scratches or damage that can lead to defective products, offer a range of laminar gas diffusion products allowing materials to float harmlessly during transport. These products, typically customized in stainless steel and available in various alloys, support unique assembly designs in manufacturing material handling scenarios.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Material Transport

- Liquid Handling

- Robotics and Automation Systems

Porous Metal Overview

Check out the features and benefits of Mott sintered porous metal media that delivers uniform porosity for superb filtration efficiency and structural integrity.

Additive Manufacturing Overview

Our additive manufacturing capabilities provide the most uniform porosity and unique geometries for your application.

Enhancing Manufacturing Material Handling with Mott's Solutions

In the world of manufacturing material handling, Mott’s advanced porous designs are revolutionizing how sensitive materials are transported during production processes. These innovative products ensure the safe and efficient movement of materials, crucial in achieving high yield and quality in manufacturing. Mott’s laminar gas diffusion technology, often used in manufacturing material handling, allows materials to be transported smoothly and without damage, akin to floating on an air hockey table. This not only reduces the risk of defects caused by surface damage but also streamlines the overall manufacturing process.

FAQs: Manufacturing Material Handling

Q: What is Manufacturing Material Handling?

A: Manufacturing material handling refers to the movement, protection, storage, and control of materials and products throughout the manufacturing, warehousing, distribution, consumption, and disposal processes.

Q: How does Mott’s technology contribute to Manufacturing Material Handling?

A: Mott’s technology, particularly their porous designs and laminar gas diffusion products, plays a crucial role in ensuring the safe and efficient transport of sensitive materials, thereby enhancing the overall efficiency and quality of manufacturing processes.

Q: Why is efficient Material Handling important in manufacturing?

A: Efficient material handling in manufacturing is vital for minimizing product damage, reducing handling costs, improving productivity, and maintaining a smooth flow of materials throughout the production cycle.

Q: Can Material Handling systems be automated?

A: Yes, material handling systems in manufacturing can be highly automated, using technologies such as conveyor belts, robotic arms, and automated guided vehicles (AGVs) to improve efficiency and reduce manual labor.