Carbon Black

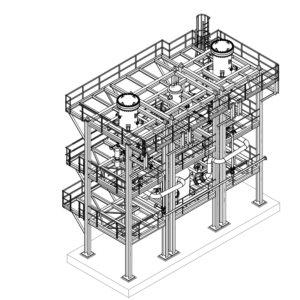

Carbon black, produced from highly purified, filtered feedstock, is a key ingredient in tire production and other rubber products, and is also used as a pigment in inks and paints. Manufacturers rely on Mott’s carbon black filter solutions to filter carbon black feedstock, effectively removing contaminants and ensuring the consistent production of highly pure carbon black product.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Needle Coke Production

Process Filtration Overview

A comprehensive overview of Mott's offerings for process filtration applications.

Porous Metal Elements Overview

Explore the features and benefits of Mott sintered porous metal media for superb filtration efficiency, structural integrity and uniform porosity.

Mott Design Process

We take a scientific approach to filtration system design to not only ensure your project stays on time and on budget, but also to ensure it operates at peak efficiency.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

What is Carbon Black?

Carbon black is a fine black powder primarily used as a reinforcing agent in rubber products, notably tires, and as a pigment in various applications like inks and paints. Its production involves the partial combustion of hydrocarbons, resulting in a highly pure and granular form of carbon. In this critical process, Mott Corp plays an essential role with their advanced carbon black filter technology. These filters are specifically engineered to purify the carbon black feedstock, ensuring the removal of contaminants and consistency in the quality of the final product. Mott Corp’s commitment to precision and efficiency in filtration significantly enhances the overall production process of carbon black, making them a key contributor in this industry.

FAQs: Carbon Black Feedstock Filters

Q: What is a carbon black feedstock filter?

A: A carbon black filter is a specialized type of filtration system designed to remove impurities and contaminants from feedstock used in the production of carbon black. This filtration is crucial for achieving the high purity required for carbon black, which is used in various applications like tire manufacturing, rubber products, and as a pigment in inks and paints.

Q: How does Mott Corp’s carbon black feedstock filter enhance the production process?

A: Mott Corp’s carbon black filter enhances the production process by providing advanced filtration that ensures the removal of even the smallest impurities. This leads to a more consistent and high-quality carbon black product, necessary for applications where product performance is critical. Mott’s filters are designed for high efficiency and reliability, making them integral to the carbon black production process.

Q: What are the benefits of using Mott Corp’s carbon black feedstock filters in manufacturing?

A: Using Mott Corp’s carbon black filters in manufacturing offers several benefits, including improved product quality, reduced downtime due to less frequent filter replacements, and overall process efficiency. These filters help in maintaining the purity of the carbon black, which is essential for the quality of the final products, such as tires and pigments.

Q: Can Mott Corp’s carbon black feedstock filters be customized for specific needs?

A: Yes, Mott Corp offers customization options for their carbon black filters to meet specific industrial requirements. Understanding that each production process can be unique, Mott Corp designs their filters to accommodate various particle sizes, flow rates, and other specific conditions, ensuring optimal performance and efficiency for each application.