Catalyst Hopper Vents

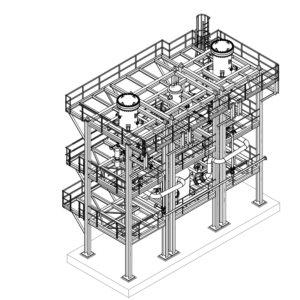

Mott GSV (Gas Solids Venturi) filters effectively and reliably capture catalyst fines during catalyst transfer operations in FCC catalyst hoppers. This includes tasks like loading fresh catalyst from a truck or unloading spent catalyst into the catalyst hopper from the regenerator. The back-pulse operation of these filters occurs automatically and efficiently, maximizing catalyst recovery while minimizing utility consumption. Additionally, the durability of Mott’s porous metal filter elements, integral to the catalyst hopper system, ensures years of reliable service, making it a vital component in refinery operations.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Catalyst Fine Removal in Refineries

GSV Filters

GSV Filter Systems - Gas Solids Venturi Pulse Blowback

Mott Design Process

Our five-step design process will ensure you receive the right filtration unit for your capital investment.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Optimizing Refinery Operations with Catalyst Hopper Vent Filters

Mott’s catalyst hopper vent filters are an integral part of refinery operations, designed to enhance the efficiency and safety of catalyst handling. This system plays a crucial role in the transfer and recovery of catalyst fines, using advanced filtration technology to ensure minimal loss and maximum purity. The incorporation of the Mott GSV (Gas Solids Venturi) filters allows for seamless and reliable loading of fresh catalysts and unloading of spent catalysts, all while maintaining optimal environmental compliance. Mott’s commitment to durability and efficiency is evident in the design of this system, making it a trusted solution for refineries aiming to optimize their catalyst handling processes.

FAQs: Catalyst Hopper Vents

Q: What are catalyst hopper vents and how do they function?

A: Catalyst hopper vents are specialized components used in refining and chemical processing industries, specifically designed for the vents of catalyst hoppers. These vents are essential for maintaining pressure balance and preventing the escape of fine particles during the transfer and storage of catalysts in hoppers. They work by allowing gases to escape while trapping catalyst particles, ensuring safe and efficient operation.

Q: How do Mott Corp’s catalyst hopper vent filters enhance safety in refineries?

A: Mott Corp’s catalyst hopper vent filters significantly enhance safety in refineries by preventing the buildup of pressure and potential emissions of fine catalyst particles into the environment. This is crucial for maintaining operational safety standards and ensuring compliance with environmental regulations. The filter design ensures that they operate reliably even under the demanding conditions typical in refinery operations.

Q: What makes Mott Corp’s catalyst hopper vent filters unique?

A: Mott Corp’s catalyst hopper vent filters stand out due to their advanced filtration technology, which efficiently separates fine catalyst particles from gases. This ensures a clean release of gases while retaining valuable catalyst materials. Their durability and design are tailored to withstand the harsh conditions of refinery operations, making them a reliable choice for these critical applications.

Q: Can Mott Corp customize catalyst hopper vent filters for specific applications?

A: Yes, Mott Corp offers customization options for their catalyst hopper vent filters to suit specific industrial applications. Understanding the varied needs of different refineries and processing plants, Mott Corp designs these filters considering factors such as hopper size, catalyst type, and operational pressures, ensuring optimal performance and safety in each unique setting.