Loop Heat Pipe Technology

Mott’s sintered media pore structure, with its unique wicking properties driven by capillary action of amorphous metal particles, plays a crucial role in loop heat pipe applications. For instance, in loop heat pipe systems, a custom-designed interior can facilitate the wicking of process water 360 degrees around the pipe, ensuring uninterrupted and uniform heat distribution.

Loop heat pipes serve as passive heat exchangers, efficiently transporting thermal energy even in scenarios where conventional heat pipes prove ineffective, such as when there’s a significant temperature difference between the heat source and sink. They offer an efficient and pump-free solution for transporting heat over long distances, making them indispensable in various thermal management applications.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Let Mott make your life easier with our loop heat pipe technology and components designed to:

- Transport heat over long distances without a pump or other moving parts.

- Wick process fluid 360 degrees around the pipe for uniform heat distribution.

- Remain customizable to achieve desired wicking performance across many industry applications.

Typical Applications

- Electronics cooling

- Space vehicles thermal control

- Advanced weapons thermal systems

- Surgical and diagnostics devices

- Laser diodes

- Heat exchangers

Porous Metal Overview

Check out the features and benefits of Mott sintered porous metal media that delivers uniform porosity for superb filtration efficiency and structural integrity.

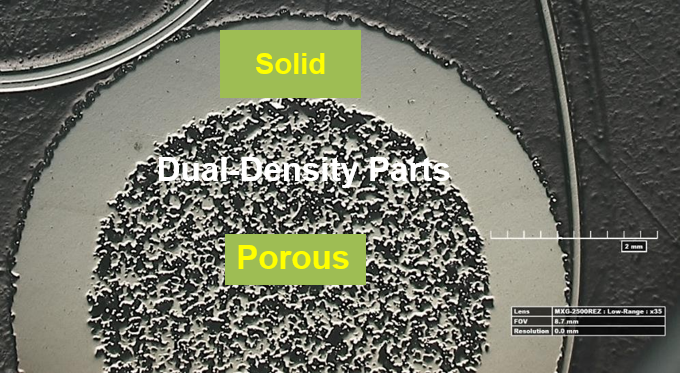

Additive Manufacturing

Our additive manufacturing capabilities provide the most uniform porosity and unique geometries for your application.

Lab and Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Computational Fluid Dynamics Services

Computational Fluid Dynamics (CFD) modeling is an excellent service to accelerate product development. It allows for cost-effective equipment sizing and identification of optimal operational parameters.

Product Specs

| Dimensions |

Length – Tube form wicks: Standard Diameters – 1”, 1.5”, 2”, 2.5”, 2.75”, 3” Wall Thickness – .039” to .093” (Dependent on media grade) Custom options are available, consult factory |

|---|---|

| Material Choices |

Standard filter and hardware alloys – 316L SS, 310 SS, Titanium, Inconel® 600, Hastelloy® C-276, Hastelloy® X, Monel® 400, Nickel 200 Other alloys are available, consult factory |

| Hardware Options |

Extension hardware and fitting options available for full assembly – Standard piping, End-fittings like compression, NPT, or VCR® Custom options available, consult factory |

| Media Grades |

Nominal pore sizes available – 0.2, 0.5, 2, 5, 10, 20, 40, 100 Custom options available, consult factory |

| Performance Testing |

Lab validation tests available |

Videos & Articles

Our Design Capabilities

- Explore our diverse hardware options tailored for various applications.

- Utilize our advanced additive manufacturing capabilities to achieve precise designs.

- Experience the unique wicking properties of Mott’s 3D printed media pore structure, driven by capillary action of amorphous metal particles, ideal for loop heat pipe applications.

- Benefit from custom-designed interiors that facilitate 360-degree wicking of process fluid around the pipe, ensuring uniform heat distribution and preventing fluid buildup.

Relevant Services

- Tailored Design Solutions: Benefit from our end-to-end design expertise as we customize solutions to meet your specific parameters, including loop heat pipe applications.

- Advanced Fluid Modeling: Leveraging our extensive experience, we offer accurate flow models to provide initial performance and feasibility estimates, crucial for loop heat pipe prototypes.

- Extensive Partner Network: With a vast network of partners, we ensure access to new materials, advanced manufacturing capabilities, and validation testing services, essential for loop heat pipe development.

- Engineering Support: Beyond component-level assistance, our team provides comprehensive systems design support, catering to all your loop heat pipe requirements.

- Industry Applications: Professionals across various fields, such as satellite project and product engineers, thermal management system designers, and anyone seeking efficient heat transport solutions, can benefit from Mott Corp’s loop heat pipe technology.

- Contact us today at 860-864-4927 to learn more about Mott’s loop heat pipe components and discuss how we can address your unique application needs.

Innovative Solutions with Mott's Loop Heat Pipes

Mott’s loop heat pipes are advanced heat transfer devices designed to efficiently transport thermal energy over long distances without the need for mechanical pumps. These heat pipes are particularly beneficial in scenarios where conventional heat transfer methods prove ineffective, offering a reliable solution for thermal management challenges. By utilizing a closed-loop system with a working fluid, Mott’s loop heat pipes ensure uniform heat distribution and prevent fluid buildup, making them ideal for various applications in industries such as aerospace, electronics cooling, and renewable energy systems.

FAQs: Loop Heat Pipe

Q: What is a loop heat pipe?

A: A loop heat pipe is an advanced heat transfer device used to transport thermal energy over long distances without the need for mechanical pumps. It consists of a closed-loop system with a working fluid that evaporates at the heat source, travels through a loop to release heat, condenses at the heat sink, and returns to the evaporator via capillary action.

Q: How does a loop heat pipe work?

A: A loop heat pipe operates on the principle of phase change heat transfer. At the heat source, the working fluid evaporates, absorbing heat energy. The vapor travels through a loop to the heat sink where it condenses, releasing heat. Capillary action then returns the condensed fluid to the evaporator, completing the loop and allowing for continuous heat transfer.

Q: What are the advantages of using loop heat pipes?

A: Loop heat pipes offer several advantages, including high thermal conductivity, efficient heat transfer over long distances, passive operation without the need for mechanical pumps, and uniform temperature distribution. They are particularly useful in applications where traditional heat transfer methods are impractical or insufficient.

Q: What industries benefit from loop heat pipe technology?

A: Loop heat pipes find applications in various industries, including aerospace, electronics cooling, renewable energy systems, thermal management in satellites, and high-performance computing. They are used wherever efficient and reliable heat transfer is essential, especially in environments with space or weight constraints.