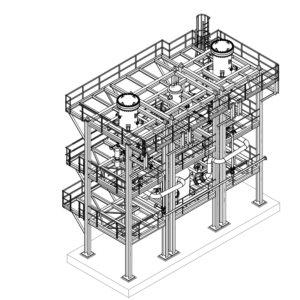

Catalyst Recovery Filters

Mott’s catalyst recovery filtration system is expertly crafted to capture over 99% of the catalyst, making it ideal for either recycling or reclamation while ensuring superior filtrate quality. The Mott HyPulse® LSI, a leading catalyst recovery filter, can be tailored for various clean-in-place backwashes, from discharging roughly 15 wt.% slurry to around 50 wt.% wet cake. For scenarios with a significant presence of submicron particles, the HyPulse® LSX cross-flow filter ensures less than 50 ppm filtrate quality, eliminating concerns about blinding media with minuscule catalyst particles. In cases involving dense particles like Raney Nickel, the HyPulse® LSM stands out, offering a flexible filtration and backwash operation. This system capitalizes on the natural high-particle density through gravity settling, making it adept at handling high solids loading streams. All these catalyst recovery filtration technologies are tailored to specific process conditions and can endure operating temperatures up to 1700°F, high operating pressures, and even harsh corrosive environments.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Palladium Recovery

- Platinum Recovery

- Rhodium Recovery

- Nickel Recovery

Process Systems Overview

A comprehensive overview of Mott's offerings for process filtration applications.

Elements

Explore the features and benefits of Mott sintered porous metal media for superb filtration efficiency, structural integrity and uniform porosity.

Mott Design Process

We take a scientific approach to filtration system design to not only ensure your project stays on time and on budget, but also to ensure it operates at peak efficiency.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

What are Catalyst Recovery Filters?

Catalyst recovery filters are specialized filtration systems designed to capture and reclaim catalysts used in various industrial processes. These filters ensure that over 99% of the catalyst is recovered, either for recycling or reclamation, thereby optimizing resource utilization and reducing costs. By employing these filters, industries can achieve excellent filtrate quality, ensuring that the recovered catalysts maintain their efficacy. The use of such filters is essential for sustainable and efficient industrial operations, especially in sectors where catalysts play a pivotal role.

FAQs: Catalyst Recovery Filters

Q: What is the primary purpose of Mott’s liquid filter technologies in catalyst recovery?

A: Mott’s liquid filter technologies are specifically designed for catalyst recovery, capturing over 99% of the catalyst. This ensures either efficient recycling or reclamation while maintaining excellent filtrate quality.

Q: How does the Mott HyPulse® LSI filter contribute to the catalyst recovery?

A: The Mott HyPulse® LSI filter system can be tailored for various clean-in-place backwashes, discharging from about 15 wt.% slurry to roughly 50 wt.% wet cake, making it versatile in handling different catalyst consistencies.

Q: Are there any specific filters designed for applications with submicron particles?

A: Yes, for applications with significant submicron particles, the HyPulse® LSX cross-flow filter is ideal. It achieves less than 50 ppm filtrate quality and ensures that the media isn’t blinded by small catalyst particles, enhancing the efficiency of the catalyst recovery process.

Q: How does the HyPulse® LSM handle applications with dense particles in the catalyst recovery process?

A: For applications with dense particles, such as Raney Nickel, the HyPulse® LSM is a standout in the catalyst recovery filtration system. It offers configurable filtration and backwash operations and leverages the natural high-particle density with gravity settling to manage high solids loading streams effectively.

Q: Can Mott’s catalyst recovery technologies handle extreme conditions?

A: Absolutely. All three of Mott’s catalyst recovery technologies, including the filters and systems, are designed to specific process conditions. They can endure operating temperatures up to 1700°F and withstand high operating pressures and challenging corrosive environments.