Food Oil Intermediate Filters

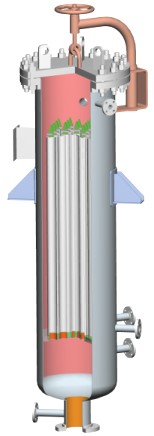

Mott food oil intermediate filters excel at removing catalyst, bleaching agents, solidified product, and other solid contaminants from a variety of alcohol, acid, or oil-based processes. Whether it’s palladium-on-carbon catalyst from a hydrogenated oil stream or bleaching agents from edible oil or detergent precursors, the Mott LSI filter is ideal for automated, closed-loop operation with clean-in-place backwashing for food oil intermediate filtering needs. Generally done without the need for additional filter aids, the Mott LSI can filter streams with catalyst less than 1 micron in size and with solids loading up to 5+ wt.%. The backwash system for these food oil intermediate filters can be designed to discharge between an approximate 15 wt.% slurry to an approximate 50 wt.% wet cake, providing efficient and effective filtration for intermediate stages in food and oil processing.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Hydrogenated Oil Catalyst Removal

- Detergent Bleaching Agent Removal

- Edible Oil Bleaching Agent Removal

- Edible Oil Activated Carbon Removal

Process Filtration Overview

A comprehensive overview of Mott's offerings for process filtration applications.

Mott Process Design

Our systems are designed using a graded design approach. This approach includes filter feasibility testing, pilot testing, engineering design, filter system fabrication, and operational support.

Elements Cleaning Guide

Porous metal media is made to last a lifetime. This cleaning guide provides proper care and cleaning instructions to ensure longevity and reliability.

Catalyst Filtration Brief

Catalyst Recovery Filtration Application Brief Installation Examples. LSI, LSM, LSX Filters

Filter Feasibility Testing

Filter feasibility testing and application analysis for liquid and gas filtration processes.

Product Specs

| Vessel Diameter |

Standard Diameters – 4” to 72” diameter vessels are standard to accommodate a wide range of flow rates. Custom vessels are available upon request, consult factory |

|---|---|

| Filtration Efficiency |

Media grade elements down to 0.2 um are available to capture even the smallest particles in your process for a pure end product. |

| Material Choices |

Standard filter element alloys – 316L SS, 310 SS, Hastelloy C-276, Hastelloy X, Monel 400, Nickel 200, Inconel 600 Standard vessel alloys – 316L SS, Hastelloy Other alloys are available, consult factory |

| Operating Temperatures |

Alloys with temperature resistance up to 1700 degrees Fahrenheit are available. Custom alloys available to accommodate unique operating temperatures, consult factory |

| Cleaning |

Mott LSI filters for catalyst processes are designed for clean-in-place performance, meaning filter elements can discharge cake build-up without having to open the filter for maintenance. Once a terminal pressure drop has been reached, the cleaning cycle automatically initiates to discharge cake build-up through gas assisted pulse or through a backwash cycle. Particles will embed in the filter media over time, requiring the elements to be cleaned by a third-party company. Various cleaning techniques can be used to prolong life of the elements. For a recommendation of a cleaning company, please contact a Mott representative. It is recommended you have a spare set of filter elements to continue operations while elements are being cleaned. |

Videos & Articles

The Mott Filter Design Process

- Filter Feasibility Testing – In our Customer Innovation Center, we will replicate, or very closely correlate, your process conditions to determine the appropriate media grade and material for your application, including food oil intermediate filters. We will provide you with a comprehensive, in-depth analysis to prove the feasibility of using porous metal for food oil intermediate filtration in your process and furnish you with a comprehensive ROI justification.

- Pilot Testing – As an option, we can install a pilot unit in your facility enabling you to witness, first-hand, how our food oil intermediate filters will perform in your process stream and under your actual operating temperatures and pressure conditions.

- Front-End Engineering Design – Our Front-End Engineering Design (FEED) process provides you with a complete process engineering package for food oil intermediate filters, including vessel drawings, a preliminary equipment layout drawing, piping and instrumentation diagram, process flow diagram, valve and instrument list, and a detailed process functional description.

- Fabrication – When it comes to fabricating your system, we can handle as much or as little as you need – from fabricating only the filter vessel to providing a complete turnkey skid system designed for food oil intermediate filtration.

- Operational Support – When your filtration system, including food oil intermediate filters, is complete, our professionals can provide equipment commissioning and startup services, training, ongoing technical support, and quality assurance testing for the life of your system.

Depending on your needs, Mott can provide just the filter elements, a vessel and elements, or provide you a full turnkey system with the vessel, frame, piping, instruments, and controls tailored for food oil intermediate filtration.

Relevant Services

Filter Feasibility Testing – Want a recommendation on the correct filter media, alloy, and backwash frequency for your process, specifically for food oil intermediate filters? Coordinate with a Mott representative to send a sample of your feedstock to our lab to determine the correct filtration design for your process.

Preventative Maintenance Cycles – Consult with a Mott representative about utilizing a pre-determined lab testing and cleaning schedule to avoid costly downtime for your food oil intermediate filters.

Engineering Support – Utilize our expert project engineers to design the right filter elements to maximize flow and particle capture for food oil intermediate filtration.

Destructive Element Analysis – Send us one of your food oil intermediate filter elements for various analyses to determine the remaining lifetime and filtration efficiency of your filters.

Enhancing Purity with Food Oil Intermediate Filters

Mott’s food oil intermediate filters are designed to meet the critical purity requirements of the food and oil processing industries. These filters excel in removing unwanted contaminants such as catalysts, bleaching agents, and solidified products from various stages of food oil processing. By utilizing advanced porous metal technology, our food oil intermediate filters ensure high efficiency and reliability in capturing particles down to the micron level. Ideal for applications requiring the utmost in product quality and consistency, these filters play a crucial role in improving product yields and protecting downstream equipment, making them an essential component in the production of edible oils and related products.

FAQs: Food Oil Intermediate Filters

Q: What are food oil intermediate filters?

A: Food oil intermediate filters are specialized filtration devices designed for use in the food processing industry, particularly in the stages of oil production. These filters are engineered to remove impurities such as catalyst particles, bleaching agents, and solid contaminants from oil, ensuring high purity and quality in the final product.

Q: How do food oil intermediate filters improve the oil processing workflow?

A: Food oil intermediate filters streamline the oil processing workflow by efficiently removing unwanted contaminants, which can affect the taste, color, and overall quality of the final product. By ensuring cleaner oil, these filters help in maintaining consistent product quality, reducing downtime caused by equipment fouling, and extending the lifespan of downstream processing equipment.

Q: Can food oil intermediate filters handle different types of oils and processing conditions?

A: Yes, food oil intermediate filters are versatile and can be used with a wide range of vegetable and edible oils, including palm, soybean, canola, and olive oil. They are designed to withstand various processing conditions, including high temperatures and pressures, making them suitable for different stages of oil production.

Q: Are food oil intermediate filters easy to clean and maintain?

A: Many food oil intermediate filters are designed with clean-in-place (CIP) capabilities, allowing for easy cleaning without the need to disassemble the filtration system. This feature minimizes maintenance time and ensures the filters remain effective in capturing contaminants over extended periods.

Q: Can food oil intermediate filters be customized to meet specific processing requirements?

A: Absolutely, food oil intermediate filters can be customized in terms of size, filtration capacity, and material to meet the specific requirements of a food oil processing facility. Customization ensures that the filtration system integrates seamlessly into existing processes, providing optimal performance and efficiency.