3D Printed Heat Exchangers

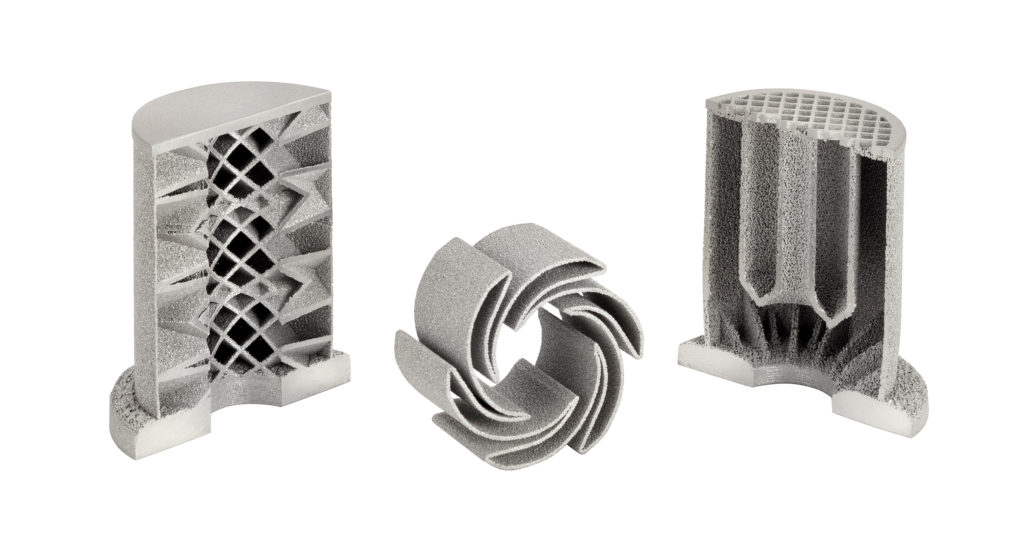

Mott stands as the global pioneer in gradient structure and controlled-porosity additive manufacturing, including 3D printed heat exchanger solutions.

Our innovative approach enables the creation of intricate component designs, allowing for the production of parts that incorporate porous or lattice structures using additive manufacturing technology. Thanks to our patent-pending process, Mott empowers you to bring to life custom 3D printed heat exchanger designs that boast unmatched features and performance, ushering in a new era of possibilities for heat exchange applications.

Whether you require enhanced heat transfer efficiency or the ability to tackle challenging thermal management tasks, our expertise in this field sets us apart as your trusted partner.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Aerospace & Defense Thermal Systems

- Electronics Cooling

- Phase Separation for Diverse Processes

- Medical Device Systems

- Temperature Sensitive Processes

Additive Manufacturing Overview

Our additive manufacturing can provide you with the most uniform porosity and unique geometries for your application.

Capabilities Brochure

Overview brochure on Mott markets served, applications, products, materials, and engineering capabilities

Computational Fluid Dynamics Services

Computational Fluid Dynamics (CFD) modeling is an excellent service to accelerate product development. It allows for cost-effective equipment sizing and identification of optimal operational parameters.

Product Specs

| Build Volume |

9.7” x 9.7” x 11.0” (L x W x H) |

|---|---|

| Build Materials |

316L Stainless Steel, Titanium, other alloys consult engineering |

| Solid feature size resolution |

+/- 0.01” |

| Porous feature size resolution |

+/- 0.02” |

| Porosity range |

1 to 100+ micron pore size (for custom porosity consult engineering) |

| Part-part dimensional consistency |

+/- 0.001-0.002” |

| Density consistency |

+/- 0.07-0.1 g/cc |

| Solid printed surface finish |

350 Ra µin |

| Machined surface finish |

5 to 32 Ra µin (same as typical hardware) |

Videos & Articles

Our Design Capabilities

- CAD design for all solid, solid-to-porous, or all porous configurations – including multi-gradient porosities

- Aggregate multiple components into a single printed Bill of Material

- Custom material and porosity printing, consult engineering

Relevant Services

Design Expertise – From start to finish, we customize solutions based on your design parameters – challenge us!

Fluid Modeling – Our extensive applications have built a library of data to increase the accuracy of our flow models to provide initial performance and feasibility estimates prior to building prototypes.

Extensive Partner Network – If a material is not listed or capability not in-house, we maintain an extensive network of partners for new material procurement, advanced manufacturing capabilities, and validation testing.

Engineering Support – If you need help beyond the component level, we also work on entire systems design. Let us know how we can help.

What are 3D printed heat exchangers?

If you’re new to the concept of 3D printed heat exchangers, Mott Corporation is here to guide you through the remarkable capabilities of this cutting-edge technology. A 3D printed heat exchanger is an innovative solution for efficient heat transfer between two fluids without them coming into direct contact. These heat exchangers are characterized by intricate, custom-designed structures that optimize thermal performance, making them ideal for applications in industries such as automotive, aerospace, energy, and more.

At Mott Corporation, we specialize in pushing the boundaries of what’s possible with 3D printed heat exchangers. Our advanced CAD design capabilities, material expertise, and engineering consultation services enable us to tailor these heat exchangers to your precise requirements, enhancing efficiency, reducing energy consumption, and opening up new possibilities in thermal management. Whether you need a single-component solution or a complex system, our team is ready to collaborate with you to harness the full potential of 3D printed heat exchangers for your specific needs.

FAQs: 3D Printed Heat Exchangers

Q: What are 3D printed heat exchangers?

A: 3D printed heat exchangers are advanced thermal management devices created using additive manufacturing technology. They feature intricate, custom-designed structures that facilitate the efficient transfer of heat between two fluids without direct contact. This technology revolutionizes traditional heat exchanger manufacturing by enabling precise customization and improved performance.

Q: What are the advantages of using 3D printed heat exchangers?

A: Using 3D printed heat exchangers offers several advantages, including enhanced thermal efficiency, reduced energy consumption, compact design, and the ability to tailor heat exchangers to specific applications. The intricate geometries achievable with 3D printing enable optimized heat transfer, making these devices ideal for various industries, such as aerospace, automotive, and renewable energy.

Q: How can I incorporate 3D printed heat exchangers into my projects?

A: To incorporate 3D printed heat exchangers into your projects, you can collaborate with specialized companies like Mott Corporation. They offer CAD design expertise, material selection, and engineering consultation to tailor heat exchangers to your specific needs. Whether you need single-component solutions or complex systems, working with experts in 3D printing ensures optimal thermal management for your applications.

Q: What industries benefit from 3D printed heat exchangers?

A: Various industries benefit from 3D printed heat exchangers. They are commonly used in aerospace for lightweight and efficient thermal control, in automotive for improved engine cooling and emissions reduction, in renewable energy for enhancing heat transfer in solar or geothermal systems, and in many other sectors where precise thermal management is crucial for performance and efficiency.