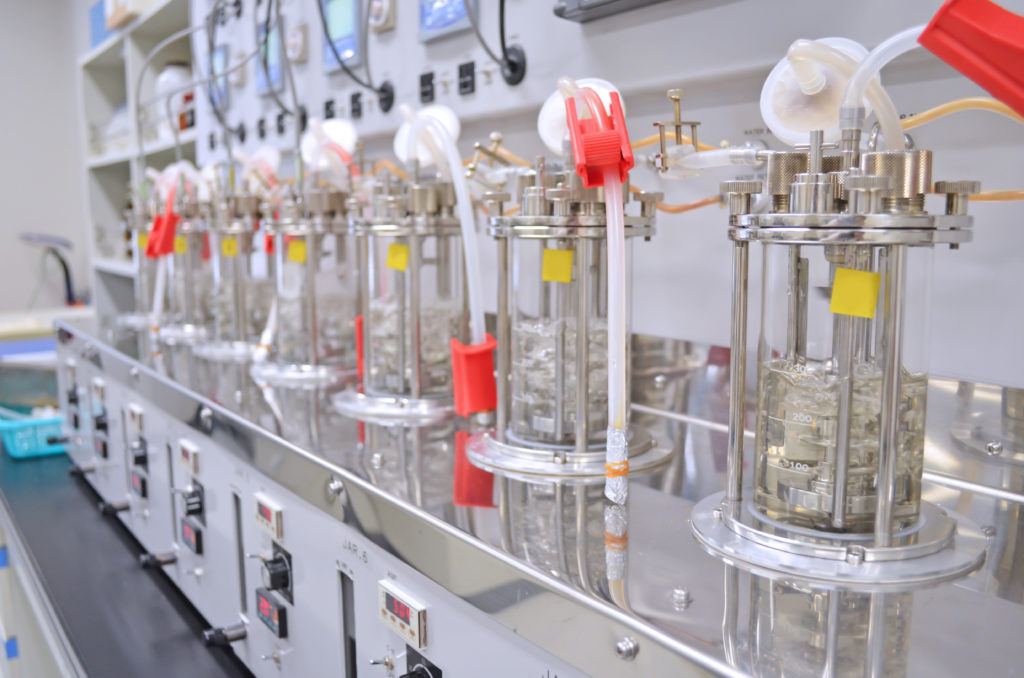

Bench Scale Equipment

We design and produce porous products for sparging, aeration, agitation, filtration and flow chemistry mixing to optimize conditions for product yield, consistency, and purity at scale-up. Mott designs and manufactures sparging, mixing and filtration assemblies for bench-top scale bioprocessing to optimize environmental conditions of cell culture for easy transfer to scale up parameters. Our products increase gas transfer efficiency for faster cell proliferation with lower gas consumption. Efficient gas transfer reduces pH monitoring hysteresis for more accurate and consistent environmental monitoring, and our flow reactors synthesize product faster and more thoroughly.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Drug Discovery

- Molecular and Cell Biology

- Bioprocess Intensification

Micro Spargers

Mott micro sparger tips for bench-top laboratory bioreactors and fermentors improve mass transfer rates by up to 400% over standard drilled pipe or single opening dip tubes.

Biofermentation Sparger

Mott biofermentation spargers are designed for optimal gas-to-liquid contacting, which results in increased gas absorption, improved throughput, and lower gas and energy costs.

Biofermentation Sparging Whitepaper

Mott's porous metal sparging system not only achieved greater O2 absorption with less agitation, but it also resulted in faster O2 absorption, significantly reducing process time.

Bioprocessing Mixers

Mott's inline static mixers are proven to be more efficient at lower dwell volumes for faster throughput in HPLC drug discovery efforts.

Computational Fluid Dynamics Services

Computational Fluid Dynamics (CFD) modeling is an excellent service to accelerate product development. It allows for cost-effective equipment sizing and identification of optimal operational parameters.

Why Mott is Your Top Choice for Bench Scale Equipment

Bench scale equipment refers to small-scale laboratory apparatus used for testing and evaluating processes or materials on a reduced scale. These systems are crucial for research and development, allowing scientists and engineers to conduct controlled experiments, analyze results, and optimize processes before scaling up to industrial levels.

Mott excels in providing the best bench scale equipment solutions by offering a wide range of customizable components and systems tailored to the specific needs of researchers and industries. With Mott’s expertise in precision engineering and materials science, their bench scale equipment ensures accurate data collection, efficient experimentation, and seamless transition to larger-scale production, ultimately saving time and resources while achieving superior results.

FAQs: Bench Scale Equipment

Q: What is bench scale equipment, and why is it important for research and development?

A: Bench scale equipment refers to laboratory-scale apparatus used in research and development (R&D) settings. It plays a crucial role in conducting experiments, testing processes, and evaluating the feasibility of new products or technologies. Researchers use bench scale equipment to obtain valuable data and insights that can guide the development of full-scale processes or products. It is essential for optimizing processes, ensuring product quality, and reducing development costs.

Q: What types of bench scale equipment does Mott offer?

A: Mott offers a wide range of bench scale equipment, including various filtration systems and testing apparatus tailored to meet the specific needs of R&D projects. Our equipment is designed to deliver precision and reliability, enabling researchers to conduct experiments with confidence.

Q: How can Mott’s bench scale equipment benefit research and development projects?

A: Mott’s bench scale equipment is engineered to provide accurate and consistent results, helping researchers make informed decisions during the development process. Our solutions are customizable, ensuring they meet the unique requirements of each project. With Mott’s equipment, researchers can streamline their R&D efforts, reduce development timelines, and achieve more cost-effective outcomes.

Q: Can Mott assist with the customization and integration of bench scale equipment into R&D processes?

A: Yes, Mott offers customization services to tailor bench scale equipment to specific research projects. Our team of experts can work closely with researchers to understand their needs and provide solutions that seamlessly integrate into their R&D processes. We also offer engineering support to ensure that the equipment operates optimally and meets project objectives.