Wicking Assembly Technology

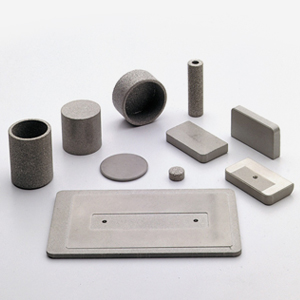

The structure of porous metal with a very uniform porosity is an integral component of a wicking assembly. This assembly efficiently pumps or wicks a liquid from a reservoir of fluid, utilizing the capillary adhesion phenomenon within the porous structure. The uniform pore distribution and pore size of this wicking assembly ensure consistent and reliable liquid transfer to the desired location, making it ideal for applications requiring precise and controlled fluid delivery. Whether it’s for medical devices, aerospace systems, or any other field where precise fluid management is essential, the reliability of a well-designed wicking assembly is paramount. Ask us about our 3d print capabilities.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Diagnostic devices and systems

- Thermal system heat pipes

- Closed electronics recirculating systems

Wicking Devices

Overview of Mott porous media for wicking applications

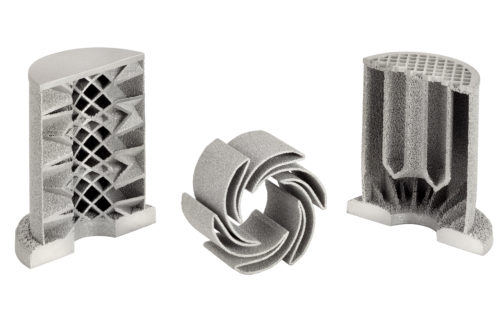

Additive Manufacturing Overview

Our additive manufacturing capabilities provide the most uniform porosity and unique geometries for your application.

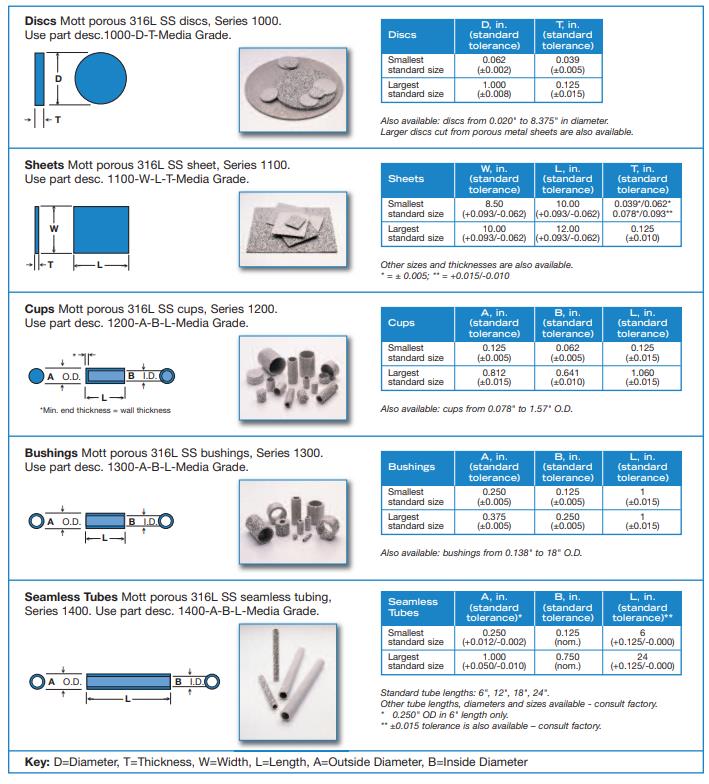

Product Specs

| Dimensions |

|

|---|---|

| Material Choices |

Standard filter and hardware alloys – 316L SS, 310 SS, Titanium, Inconel 600, Hastelloy® C-276, Hastelloy® X, Monel® 400, Nickel 200 Other alloys are available, consult factory |

| Hardware Options |

Extension hardware and fitting options available for full assembly – Standard tubing, End-fittings like compression, NPT, or VCR® Custom hardware options available, consult factory |

| Media Grades |

Nominal pore sizes available – 0.2, 0.5, 2, 5, 10, 20, 40, 100 Custom options available, consult factory |

| Performance Testing |

Lab Validation tests available |

Videos & Articles

Our Design Capabilities

- Custom filter media, pressure vessel, and fitting material and configurations available

- Complete wicking assembly configurations and system design tailored to your application

- Prototype flow testing with correlated or actual fluids

Relevant Services

Design Expertise – From start to finish, we customize solutions based on your design parameters, especially for wicking assembly applications – challenge us!

Fluid Modeling – Our extensive applications have built a library of data to increase the accuracy of our flow models, providing initial performance and feasibility estimates for your wicking assembly projects prior to building prototypes.

Additive Manufacturing – Our technology allows us to print parts with both solids and porous components in a single print cycle, ideal for complex wicking assembly designs.

Extensive Partner Network – If a material is not listed or capability not in-house, we maintain an extensive network of partners for new material procurement, advanced manufacturing capabilities, and validation testing for your wicking assembly needs.

Understanding Wicking Assembly in Mott's Solutions

Wicking assemblies play a crucial role in Mott’s innovative solutions, facilitating controlled and precise liquid transport in various applications. These assemblies are meticulously designed to efficiently move fluids from a reservoir and apply them to the desired location. The capillary adhesion principle within the wicking assembly, owing to its uniform pore distribution and pore size, ensures reliable and consistent liquid transfer. Whether used in medical devices, aerospace systems, or any field requiring accurate fluid management, exploring the significance of wicking assemblies in Mott’s solutions can help users appreciate their vital role in achieving optimal performance and reliability.

FAQs: Wicking assembly

Q: What is a wicking assembly, and how does it work?

A: A wicking assembly is a specialized component designed to efficiently transport liquid from a reservoir to a specific location. It relies on capillary adhesion within a porous structure to draw and transfer the liquid. The uniform pore distribution and pore size within the assembly enable controlled and reliable fluid transfer.

Q: Where are wicking assemblies commonly used?

A: Wicking assemblies find applications in various industries, including medical devices, aerospace, electronics, and more. They are used in situations where precise and controlled liquid transport is essential, such as drug delivery devices, cooling systems, and fuel management systems.

Q: What are the benefits of using wicking assemblies?

A: Using wicking assemblies offers several advantages, including precise liquid delivery, consistent performance, and the ability to control fluid flow rates. These assemblies are particularly valuable in situations where maintaining a specific liquid level or delivering fluids to critical components is critical.

Q: Can wicking assemblies be customized for specific applications?

A: Yes, wicking assemblies can be customized to meet the specific requirements of different applications. They can be tailored in terms of material, design, and configuration to ensure optimal performance in diverse industries and settings.