Bench Top Filtration Testing

Feasibility testing and small-scale, batch-type processes are often the initial stages before transitioning to larger pilot and process filtration systems. These early phases are crucial for assessing the effectiveness of liquid-solid and gas-solid separations. Mott’s versatile 70mm bench-top filters are designed to provide a straightforward and cost-effective method to conduct these essential separations, utilizing either vacuum or pressure-based filtration techniques. These filters serve as invaluable tools in the development and optimization of filtration processes for various applications and industries.

Questions? Call 860.747.6333 Today!

Customize Your Product Solution

If you have an existing product, we’ll customize a solution to work with it. We’re ready to start collaborating now.

Get started

Literature & Data Sheets

Typical Applications

- Liquid filtration feasibility testing

- Gas filtration feasibility testing

70mm Disc Test Filter

Barrier filtration testing to evaluate filtration performance with regard to media selection, flow rate, pressure drop, filtration quality, cake properties and backwash.

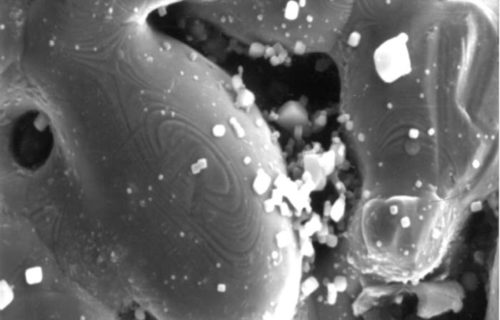

Porous Metal Overview

Check out the features and benefits of Mott sintered porous metal media that delivers uniform porosity for superb filtration efficiency and structural integrity.

Filter Feasibility Testing

Filter feasibility testing, application analysis, and information on our testing laboratory for liquid and gas filtration processes.

Lab and Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Product Specs

| Filter Disc Alloy |

316L SS and other custom materials |

|

|---|---|---|

| Media Grades |

|

|

| Disc and Cap Gasket Materials |

|

|

| O-ring Materials |

|

Videos & Articles

Our Design Capabilities

Application Engineering – Seeking guidance on your design, especially regarding bench-top filters? Our team of application engineers is prepared to assist you in selecting the right part for your design, whether it involves bench-top filters or other components. With decades of experience collaborating with renowned technical and performance brands worldwide, we’re enthusiastic about helping you tackle complex challenges.

Customer Innovation Center – At Mott, we thrive on collaborating with customers, especially on intricate projects involving bench-top filters and beyond. In fact, we’ve dedicated an entire facility to it. If you’re interested in participating in lab testing and engineering consultation sessions, consider joining us at our Customer Innovation Center in Connecticut. Here, we work together to develop tailored solutions for your unique application needs.

Relevant Services

Lab Testing – If you need data packages or feasibility testing for your part prior to installation, we’re happy to work with you. We’ll use our lab center to perform various characterization and performance tests to ensure your parts are meeting strict specifications.

Computational Fluid Dynamics – If you would like to model your process fluids interaction with your Mott requested part, ask your Mott representative how we can model it using CFD software.

Engineering Memberships – If you’re constantly working on complex designs that require the highest standards of engineering support, ask about our membership rates, which will allow you discounted rates to various lab testing, prototyping, and engineering resources.

What is Bench Top Filtration Testing?

For those less familiar with bench-top filtration testing, it’s important to recognize its pivotal role in the development and validation of filtration processes. Mott’s Bench Top Filtration Testing solutions offer a controlled and cost-effective means to assess and optimize liquid-solid and gas-solid separations at a small-scale, batch-type level. These versatile tools are invaluable for engineers and scientists in industries ranging from pharmaceuticals to chemical manufacturing, enabling them to fine-tune filtration processes before scaling up to larger systems. With Mott’s expertise in porous metal technology, our Bench Top Filtration Testing solutions ensure reliable and precise results, providing a solid foundation for process development and optimization.

FAQs: Bench Top Filters

Q: What are Bench Top Filters?

A: Bench Top Filters are specialized filtration components used in laboratory and small-scale applications to assess and optimize liquid-solid and gas-solid separations. They offer a controlled and cost-effective means to evaluate filtration processes before scaling up to larger systems, ensuring precision and reliability.

Q: Why are Bench Top Filters important in laboratory settings?

A: Bench Top Filters play a crucial role in laboratory processes, allowing scientists and researchers to fine-tune and validate filtration techniques. They provide a controlled environment for assessing the effectiveness of liquid-solid and gas-solid separations, ensuring consistent and accurate results.

Q: How do Mott’s Bench Top Filters enhance laboratory filtration?

A: Mott’s Bench Top Filters are designed with precision and reliability in mind. They utilize porous metal technology to deliver controlled and accurate filtration in laboratory applications. These filters are essential tools for scientists and researchers across various fields, offering consistent and dependable results.

Q: Can Mott provide customized Bench Top Filters for specific laboratory needs?

A: Yes, Mott specializes in offering custom solutions for Bench Top Filters to meet the unique requirements of laboratory applications. If you have specific needs or specifications, please contact us directly, and our team will collaborate with you to develop the right Bench Top Filter solution for your laboratory testing needs.