Porous Transport Layers for Electrolysis

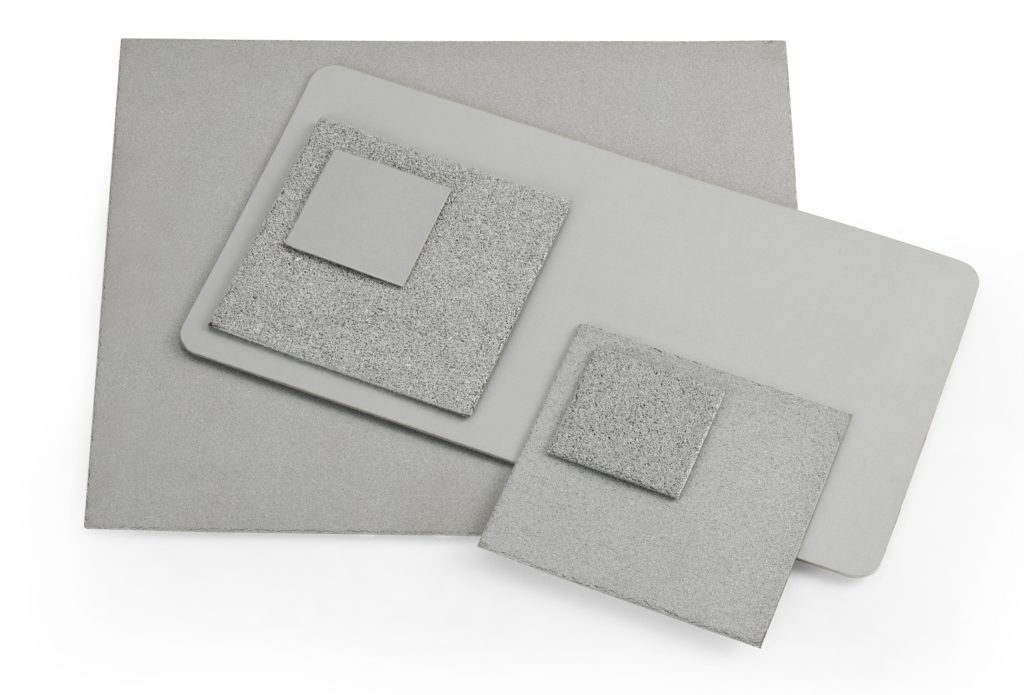

For customers working on electrolysis applications, such as hydrogen generation, Mott supplies titanium porous transport layers (PTLs) as thin as .010” for use in megawatt-class cell stacks. PTLs can be customized in length, width, and thickness for perfect compliance with any cell package. Mott’s class-leading PTL surface engineering ensures optimal anode catalyst utilization, enhanced reactant transport, and protection for thin membranes in the most demanding next-generation deployments. In addition to titanium, Mott offers other porous transport layer materials to meet application-specific requirements, including nickel, stainless steel, and niobium.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

For engineering and manufacturing applications, the results of electrolysis are limited by the quality of the equipment and processes used. Efficient, consistent electrolysis requires finely calibrated, intelligently designed equipment. Oftentimes, getting the right results is a matter of having the correct porous transport layers – or PTLs – for your particular electrolysis applications. PTLs, also known as titanium sheets, are thin components in an electrolytic cell. These titanium porous transport layers provide the ideal surface area and flowage for use in high-end electrolysis applications.

Typical Applications

- Hydrogen generation and storage

- Various fuel cell applications

- On-site gas generation

- Gas generation in spacecraft

Porous Transport Layers for PEM Electrolysis

Porous transport layers (PTLs) from Mott are preferred in electrolysis applications due to an ultra-smooth design resulting in improved catalyst utilization and extended stack lifetime.

Porous Transport Layer Performance

Enable ultra-low iridium loadings without compromising on performance

Porous Transport Layer (PTL) Case Study

Mott Porous Transport Layers achieve high power densities in gas generation applications due to a proprietary ultra-thin design resulting in better mass transport and a smaller footprint.

Titanium Sheet Quality Standards

Mott Corporation's acceptance criteria for ultra-thin sheet used in PEM electrolyzers. For a titanium sintered porous sheet to remain usable and reliable in a high-intensity porous transport layer application the titanium must be of a very specific quality. Mott’s experts have an in-depth understanding and knowledge of titanium and the other materials we use to build the custom high-end porous transport layer systems that contribute to the success of our partners’ projects.

Maximizing Efficiency with Titanium Porous Transport Layers

Titanium porous transport layers are integral in enhancing electrolysis and fuel cell technologies. These layers, specifically designed by Mott, ensure optimal gas and liquid flow, significantly boosting efficiency and durability. Mott’s titanium porous transport layer offers a high-quality solution for advanced energy systems, marking a pivotal advancement in the field.

Product Specs

| Length |

Common Lengths – 10″, 20″ Sheet can be laser cut or sheered into smaller pieces if needed. If you need a custom length, please consult factory. |

|---|---|

| Width |

Common Widths – Less than 11” Sheet can be laser cut or sheered into smaller pieces if needed. If you need a custom width, please consult factory. |

| Thickness |

Common Thicknesses – .010-.125” (dependent on media grade) Custom lengths available, consult factory |

| Media Grades |

Common Media Grades – 10 Custom media grades available upon request, consult factory |

| Materials |

Common alloys – 316LSS, Titanium, Nickel 200, Hastelloy C-276, Inconel 600 Custom alloys available upon request, consult factory |

| Temperatures |

Alloys with temperature resistance up to 1700 degrees Fahrenheit are available. Custom alloys available to accommodate unique operating temperatures, consult factory |

Videos & Articles

Our Design Capabilities

Application Engineering – Need consultation on your porous transport layer design or choosing the right titanium sheet? Our team of application engineers are ready to help you determine the right part for your design. With decades of experience of working with the world’s largest technical and performance brands, we’re eager to solve complex problems with you.

Customer Innovation Center – We enjoy working with customers on complex projects involving porous transport layers and other components. In fact, we’ve dedicated an entire facility to it. Want to join us for various lab testing and engineering consultation sessions? Visit our Customer Innovation Center in Connecticut to develop a solution for your unique application involving titanium sheets and more.

Rapid Prototyping Cell – Trying to determine the feasibility of your porous transport layer design as fast as possible? Use our rapid prototyping cell to turn around prototypes in as little as 2 weeks. Our engineers will work with equipment similar to our manufacturing facility to provide you with a manufacturable, economical design.

Additive Manufacturing – If you’re looking for the most uniform porosity in a titanium sheet or a non-traditional design, look no further than working with our porous 3D printing team. We can create controlled porosity designs with various density gradients in non-traditional shapes to satisfy the most unique design request. Our technology allows us to print parts with both solid and porous in a single print cycle. Unconventional installations and specialty applications that have never before been considered have become much easier to adapt and manufacture with modern 3D printing technology. Mott can even handle designing sensitive PEM Electrolyzer components, including porous transport layers, and parts and all other aspects of your hydrogen farming or spacecraft gas generation system.

Relevant Services

Lab Testing – If you need data packages or feasibility testing for your porous transport layer or titanium sheet part prior to installation, we’re happy to work with you. We’ll use our lab center to perform various characterization and performance tests to ensure your parts are meeting strict specifications.

Computational Fluid Dynamics – If you would like to model your process fluids interaction with a Mott porous transport layer or any other Mott part, ask your Mott representative how we can use CFD software.

Engineering Memberships – If you’re constantly working on complex designs, especially those involving titanium sheets and porous transport layers, that require the highest standards of engineering support, ask about our membership rates. These rates allow you discounted access to various lab testing, prototyping, and engineering resources. Mott’s specialties don’t stop at PTLs. We are dedicated to offering our partners valuable end-to-end support and investing in the long-term success of your projects. Ask about Mott’s expertise in other aspects of designing and outfitting high-end propulsion systems. We are the experts in propulsion filtration, fuel cells, and more, in addition to our unparalleled understanding of PTLs. Put our experienced professionals to work for you today!

Mott Corp can supply titanium sheet-based porous transport layers for electrolysis, as well as PEM electrolyzer components and other custom parts built to your exact needs and specifications. Or, you can bring Mott Corp’s expert engineers and consultants on board from day one and allow us to lend our years of experience and success to the design and development phase of your electrolysis application.

If you have any additional questions about titanium sheet porous transport layers or are undertaking a project related to spacecraft gas generation, contact the Mott Corporation team at 860.864.5017 or submit an information request through our online form. A Mott representative will be in touch soon to discuss how we can contribute to your project’s success.

FAQs: Titanium Porous Transport Layers for Electrolysis

Q: What is a porous transport layer (PTL)?

A: A porous transport layer (PTL) is a thin component used in electrolytic cells, typically made of materials like titanium. It’s designed with a specially-engineered porous structure to facilitate an optimal distribution of fluids, gases, heat, and electrical current in the cell.

Q: How does a titanium sheet differ from other materials when used as a porous transport layer?

A: Titanium sheets are known for their excellent resistance to corrosion. When used as a porous transport layer, titanium offers superior durability, mechanical strength, and conductivity, making it ideal for high performance electrolysis applications.

Q: Why are porous transport layers essential in electrolysis applications?

A: Porous transport layers play a crucial role in determining the efficiency and performance of an electrolytic cell. They ensure an optimal interaction between the reactants and the electrodes, enabling efficient electrolysis at high production rates.

Q: Can I customize the porosity of a titanium sheet used as a PTL?

A: Yes, many manufacturers, including Mott Corp, offer customization options for the porosity of titanium sheets used as PTLs. This allows for tailored performance based on specific application needs.

Q: Are there any alternatives to titanium sheets for porous transport layers?

A: While titanium is a popular choice due to its properties, other materials like stainless steel or nickel alloys can also be used for porous transport layers in some electrolysis applications. Consult with the experts at Mott to determine how alternative materials can be customized for your specific needs.

Q: Are titanium sheet-based porous transport layers environmentally friendly?

A: Titanium is known for its durability and longevity, which means that titanium sheet-based PTLs have a long lifespan, reducing the need for frequent replacements. Additionally, titanium is recyclable, making it a more environmentally friendly option compared to some other materials.