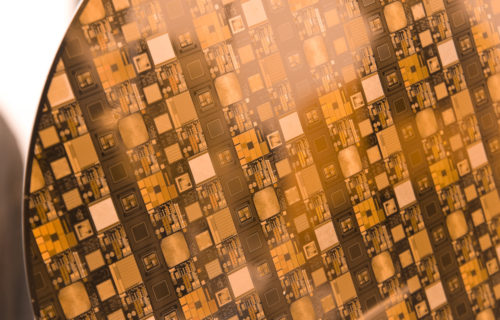

GasShield® Surface Mount Filters

Mott GasShield® Surface Mount Filters offer top-of-the-line 0.0015 μm filtration capabilities in integrated gas systems employed in semiconductor OEM tools. These GasShield® Surface Mount Filters are designed to fit seamlessly into the 1.125” and 1.5” four-fastener, surface-mount gas distribution systems, featuring both C-seal and W-seal configurations. They are compatible with a wide range of inert gases as well as most specialty gases.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

For use with W-seal and C-seal, 1.125” and 1.5” surface mount modular gas delivery systems.

Mott Semiconductor Products Catalog

Explore Mott’s wide range of high purity filters, diffusers and flow restrictors designed exclusively for semiconductor manufacturers.

Product Specs

| Operating Conditions |

» Maximum Operating Pressure: 1800 psig (124.1 barg) » Maximum Operating Temperature for Inert Gas: 460°C » Maximum Differential Pressure: 500 psid (34.4 bar) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Materials |

» Hardware: 316LSS or Alloy 22* » Filter Medium: Penta® Nickel, 316L SS or Alloy 22* » Wetted Hardware Surface Finish: 5 Ra » Custom materials also available *Alloy 22 or UNS N06022 is a nickel-chromium-molybdenum super-alloy commonly referred to as Hastelloy® C-22® |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specifications |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

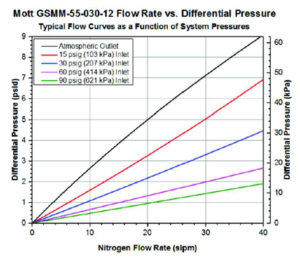

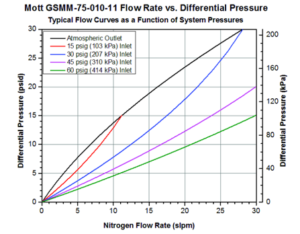

| Flow Data |

More flow curves available, consult factory or spec sheets. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

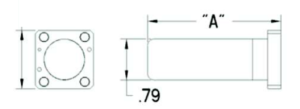

| Fittings & Dimensions |

GSMM-75 C-seal for 1.125”

GSMM-60 C-seal for 1.500”

GSMM-55 W-Seal for 1.125”

GSMM-50 W-seal for 1.500”

*Custom designs and fittings available. |

Videos & Articles

Our Design Capabilities

- Flow/pressure drop curves and filtration efficiency for virtually any system design, including those requiring a surface mount filter for semiconductor OEM tools.

- Gas compatibility considerations

- Custom filter media, pressure vessel, and fitting material and configurations available

Relevant Services

Design Expertise – From start to finish, we customize solutions based on your design parameters, whether you need a surface mount filter for semiconductor OEM tools or other specialized applications – challenge us!

Fluid Modeling – Our extensive applications have built a library of data to increase the accuracy of our flow models, ensuring the optimal performance of surface mount filters and other components. We provide initial performance and feasibility estimates prior to building prototypes.

Extensive Partner Network – If a material is not listed or capability not in-house, we maintain an extensive network of partners for new material procurement, advanced manufacturing capabilities, and validation testing, all to support the development of your surface mount filter.

Engineering Support – Utilize our expert engineers to design the right surface mount filter tailored to your specific application, guaranteeing the best filtration performance possible.

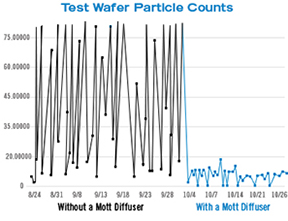

Surface Mount Filters: Enhancing Semiconductor Manufacturing

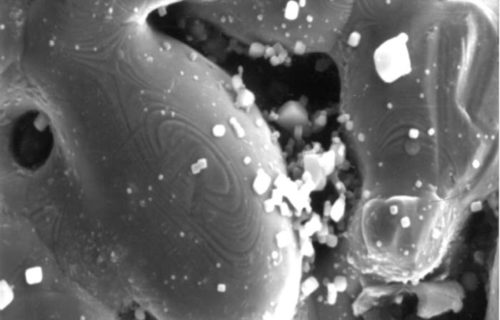

Surface mount filters are specialized filtration components used in integrated gas systems within semiconductor OEM tools. They play a crucial role in ensuring the purity and reliability of gases used in semiconductor manufacturing processes. These filters are strategically placed within gas distribution systems, efficiently removing contaminants and particulate matter as small as 0.0015 μm, ensuring gases meet stringent quality standards. Surface mount filters are essential for safeguarding sensitive semiconductor equipment, preventing contamination-induced defects, and ensuring consistent performance.

Mott stands out as a leader in providing the best surface mount filters due to its dedication to filtration excellence. Mott’s filters are engineered to deliver maximum filtration efficiency, industry-leading flow consistency, and unmatched reliability. Their expertise in customizing surface mount filters based on specific design parameters ensures each solution is tailored to meet the unique needs of various semiconductor applications. Additionally, Mott’s extensive partner network and engineering support ensure that customers receive high-quality surface mount filters that perform optimally, contributing to the overall success of semiconductor manufacturing processes.

FAQs: Surface Mount Filters

Q: What is a surface mount filter, and where is it typically used in the semiconductor industry?

A: A surface mount filter is a specialized filtration component used in the semiconductor industry to provide ultra-fine filtration for gas distribution systems within semiconductor manufacturing equipment. It is typically employed in gas systems to ensure the purity and cleanliness of gases used in various semiconductor manufacturing processes and offers an advantage of consuming less space on gas panels.

Q: What size particles do Mott’s GasShield® Surface Mount Filters remove from gases?

A: Mott’s GasShield® Surface Mount Filters provide industry-leading filtration efficiency, removing particles as small as 0.0015 μm from gases, making them ideal for critical semiconductor applications where particle control is essential.

Q: Are Mott’s surface mount filters compatible with all types of gases used in semiconductor manufacturing?

A: Yes, Mott’s GasShield® Surface Mount Filters are compatible with a wide range of gases, including inert gases and most specialty gases commonly used in semiconductor manufacturing processes.

Q: How can Mott assist in customizing surface mount filters for specific semiconductor manufacturing applications?

A: Mott offers design expertise and engineering support to customize surface mount filters based on specific design parameters, ensuring that each solution is tailored to meet the unique needs of various semiconductor manufacturing applications.