Slurry Oil Filters

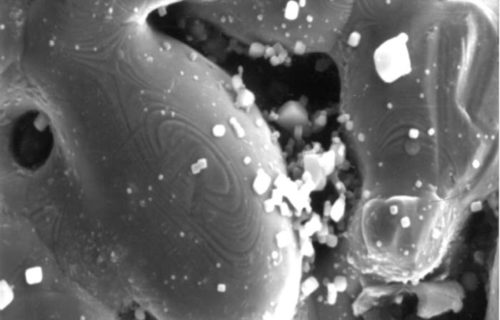

Mott’s FCC/RFCC slurry oil filters excel at removing alumina-silica and other solids contaminants from main column bottom slurry feeds. With online clean-in-place automated backwashing, our slurry oil filters achieve filtrate quality below 100 ppm total suspended solids. This ensures the filtered oil can be used for blending or sold as valuable product into other applications. Backwashed slurry can be recycled back to the riser, decanted and concentrated, or sent directly to disposal or reprocessing. Mott’s install base includes 20+ filters on five continents in both FCC and RFCC applications.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

FCC/RFCC Application Brief

HyPulse LSI filters in FCC/RFCC services can upgrade slurry oil and eliminate storage and tank cleaning.

Process Filtration Overview

A comprehensive overview of Mott's offerings for process filtration applications.

Mott Process Design

Our systems are designed using a graded design approach. This approach includes filter feasibility testing, pilot testing, engineering design, filter system fabrication, and operational support.

Elements Cleaning Guide

Porous metal media is made to last a lifetime. This cleaning guide provides proper care and cleaning instructions to ensure longevity and reliability.

Filter Feasibility Testing

Filter feasibility testing and application analysis for liquid and gas filtration processes.

Product Specs

| Vessel Diameter |

Standard Diameters – 24” to 66” diameter vessels are standard to accommodate a large range of flow rates and production volumes, ranging from 1,000 barrels per day to 20,000 barrels per day |

|---|---|

| Solid Weight % |

Weight percentages between 0.1-1% are standard, but designs can be modified to accommodate unique feed streams |

| Standard Materials |

Standard filter element alloys – 316L SS Standard vessel alloys – 316L SS Other alloys are available, consult factory |

| Operating Temperatures |

Up to 800 degrees Fahrenheit Custom alloys available to accommodate unique operating temperatures, consult factory |

| Cleaning |

LSI filters for FCC/RFCC are designed for clean-in-place performance. This means filter elements can discharge cake build-up without having to open the filter for maintenance. Once terminal pressure drop has been reached, the cleaning cycle automatically initiates. This discharges cake build-up through gas assisted pulse or through a backwash cycle. Particles will embed in the filter media over time requiring the elements to be cleaned by a third-party company. Various cleaning techniques can be used to prolong life of the elements. For a recommendation of a cleaning company, please contact a Mott representative. It is recommended you keep a spare set of filter elements to continue operations while elements are being cleaned. |

Videos & Articles

The Mott Slurry Oil Filter Design Process

- Filter Feasibility Testing for Slurry Oil Filtration – In our Customer Innovation Center, we will replicate or correlate your slurry process conditions to determine the appropriate media grade and material for your application. We will provide you with a comprehensive, in-depth analysis to prove the feasibility of using porous metal in your slurry filtration process and an ROI justification.

- Pilot Testing – We can install a pilot slurry oil filter unit in your facility. This allows you to witness first-hand how our slurry oil filters will perform in your process stream and under your actual operating temperatures and pressure conditions.

- Front-End Engineering Design – Our Front-End Engineering Design (FEED) process provides you with a complete process engineering package tailored for slurry oil filtration. FEED packages include vessel drawings, a preliminary equipment layout drawing, piping and instrumentation diagram, process flow diagram, valve and instrument list, and a detailed process functional description for slurry filtration.

- Fabrication – When it comes to fabricating your slurry oil filtration system, we can handle as much or as little as you need – from fabricating only the filter vessel, to providing a complete turnkey skid system.

- Operational Support – When your slurry oil filtration system is complete, our professionals can provide equipment commissioning and startup services, training, ongoing technical support, and quality assurance testing for the life of your system.

Relevant Services for Slurry Oil Filtration

Slurry Oil Filter Feasibility Testing – Want a recommendation on the correct filter media, alloy, and backwash frequency for your slurry oil process? Coordinate with a Mott representative to send a sample of your slurry feed stock to our lab to determine the correct filtration design for your process.

Preventative Maintenance Cycles for Slurry Oil Filters – Consult with a Mott representative about utilizing a pre-determined lab testing and cleaning schedule for your slurry filter to avoid costly downtime.

Engineering Support for Slurry Oil Filtration – Utilize our expert project engineers to design the right slurry oil filter elements to maximize flow and particle capture.

Destructive Element Analysis for Slurry Oil Filters – Send us one of your slurry oil filter elements for various analyses to determine the remaining lifetime and filtration efficiency of your filters.

FAQs: Slurry Oil Filters & Filtration

Q: What is the primary function of Mott’s FCC/RFCC slurry oil filters?

A: Mott’s FCC/RFCC slurry oil filters are designed to excel at removing alumina-silica and other solid contaminants from main column bottom slurry feeds. They ensure the production of high-quality filtrate with total suspended solids below 100 ppm.

Q: How do these slurry oil filters maintain their efficiency during operations?

A: Mott’s slurry oil filters come with online clean-in-place automated backwashing. This feature allows the slurry oil filters to discharge contaminants and maintain optimal filtration performance without frequent manual cleaning. When a terminal pressure drop is reached, the cleaning cycle automatically initiates, discharging build-up through gas-assisted pulse or a backwash cycle.

Q: What is the significance of filtrate quality in slurry oil filtration?

A: Achieving high filtrate quality ensures that the filtered oil from the slurry filtration process can be used for blending or sold as a valuable product for other applications. Mott’s slurry filters achieve filtrate quality below 100 ppm total suspended solids, ensuring the consistent production of high-quality oil.

Q: How versatile is the application of Mott’s slurry oil filters in the industry?

A: Mott’s slurry oil filters have a broad install base, with over 20 filters operating on five continents. They are used in both FCC and RFCC applications, showcasing their adaptability and efficiency in various industrial settings.