Improving Domestic Investment and National Security with Mott’s Semiconductor Components and Technologies

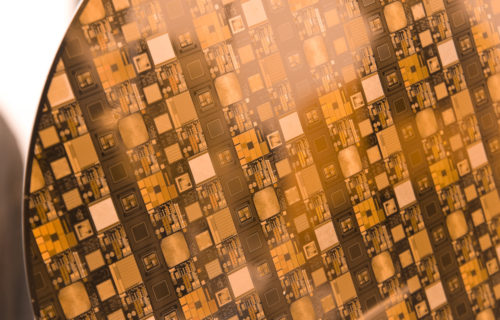

Semiconductors are vital to the modern economy, powering everything from defense systems and cars to alternative energy. But while the […]

Mott Corporation Receives $100K Grant from State of Connecticut Supporting Additive Technologies

Mott Corporation Receives $100K Grant from State of Connecticut to Support the Adoption of Additive Technologies and Advanced Printing Capabilities (FARMINGTON, […]

2024 will be a Year of Challenge and Triumph for the Semiconductor Industry

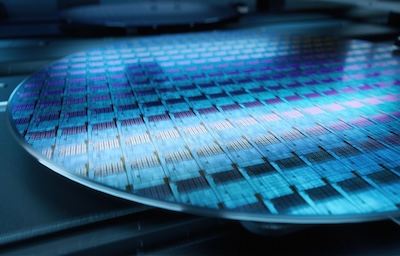

There is a debate in the semiconductor industry over whether Moore’s law remains viable. In a November 2023 article the […]

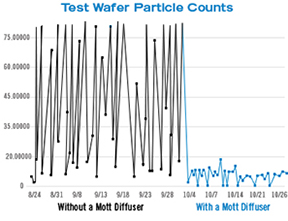

Work with Mott to Achieve Longer Tool Uptimes and Better Factory Throughput

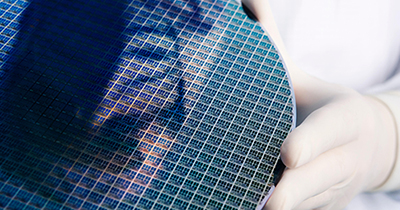

Improving tool uptime and tool throughput is critical to achieving better factory yields. Without careful tool operation, proper maintenance and […]

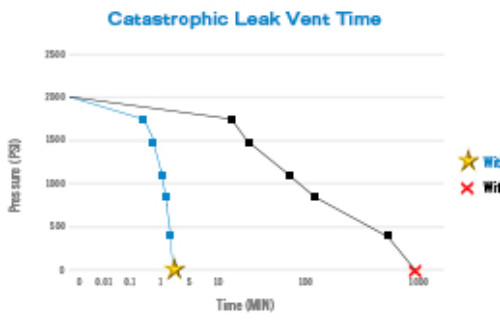

Mott Precision High Purity Flow Restrictors Save Millions on Wafer Fab Gas Vent Systems

With Mott Precision High Purity Flow Restrictors you can reduce the flow of a catastrophic gas leak in minutes, not […]

Enhance Safety in Semiconductor Wafer Fabs with Mott’s Penta® Nickel Filters

Enhancing Safety in Semiconductor Wafer Fabs with Mott’s Penta® Nickel Porous Metal Filters In the high-stakes environment of semiconductor wafer […]

How to Tackle the Top 10 Semiconductor Filtration Challenges, Part 2: Accelerating Moisture Recovery and Slaying Excessive Dry Down Times

Beneath the floor of every microchip manufacturer is a subfab containing miles of stainless-steel tubing transporting a myriad of different […]

Addressing Semiconductor Filtration Challenges | Mott Corp

Comprehensive Guide to Semiconductor Filtration In the vastly complex world of semiconductor manufacturing, precision and control are paramount. As the […]

How To Tackle The Top 10 Semiconductor Filtration Challenges: Series Intro

In today’s dynamic technological landscape, semiconductor manufacturers face a myriad of challenges, with semiconductor filtration playing a pivotal role in […]