Quick-Change Spargers for Bioreactors

In bioreactors, achieving optimal mass transfer of gases such as oxygen or carbon dioxide is often challenging. Mott quick-change spargers are designed to address this issue by greatly increasing mass transfer rates. The introduction of gases into stirred or unstirred reactor vessels via millions of tiny bubbles from quick-change spargers increases the gas-to-liquid contact areas, thereby optimizing mass transfer rates. The innovative quick-change design of these spargers enables fast changeover for new batches without the need to cut or weld sparger elements, significantly reducing downtime and increasing operational efficiency. This feature is particularly beneficial in fast-paced production environments where time is critical, making quick-change spargers an essential tool for enhancing productivity and process flexibility.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Mammalian cell bioprocessing

- Biofermentation

- Aeration

- Bench top bioreactors

Quick-Change Spargers

Mott Quick-Change Sparger System Assembly and Instructions

Computational Fluid Dynamics Services

Computational Fluid Dynamics (CFD) modeling is an excellent service to accelerate product development. It allows for cost-effective equipment sizing and identification of optimal operational parameters.

Mott Products for Biotechnology

Mott media is designed into dozens of applications in the biotechnology and pharmaceutical industries.

Product Specs

| Product Specs |

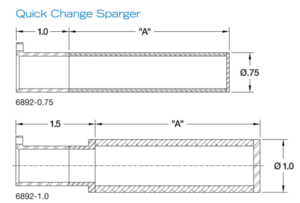

Sparger Tubes available in 3/4″ or 1″ od Sparger Tube Lengths – 1″, 2″, 3″, 4″ Media Grades – 0.5 µm, 2 µm, 5 µm, 10 µm Materials of Construction – 316L SS |

|---|

Videos & Articles

Our Design Capabilities

Application Engineering – Need consultation on your design, especially if it involves integrating quick-change spargers into your systems? Our team of application engineers are ready to help you determine the right part for your design. With decades of experience working with the world’s largest technical and performance brands, we’re eager to solve complex problems with you, including those involving quick-change spargers for efficient and flexible process management.

Customer Innovation Center – We enjoy working with customers on complex projects, particularly those requiring the advanced capabilities of quick-change spargers. In fact, we’ve dedicated an entire facility to it. Want to join us for various lab testing and engineering consultation sessions? Visit our Customer Innovation Center in Connecticut to develop a solution for your unique application, focusing on the optimal use of quick-change spargers for your specific needs.

Rapid Prototyping Cell – Trying to determine the feasibility of your design as fast as possible, especially when incorporating quick-change spargers? Use our rapid prototyping cell to turn around prototypes in as little as 2 weeks. Our engineers will work with equipment similar to our manufacturing facility to provide you with a manufacturable, economical design that effectively integrates quick-change spargers.

Additive Manufacturing – If you’re looking for the most uniform porosity or a non-traditional design that includes quick-change spargers, look no further than working with our porous 3D printing team. We can create controlled porosity designs with various density gradients in non-traditional shapes to satisfy the most unique design request, including configurations optimized for quick-change spargers. Our technology allows us to print parts with both solid and porous in a single print cycle, perfect for creating complex sparger designs that meet your exact requirements.

Relevant Services

Lab Testing – If you need data packages or feasibility testing for your part prior to installation, especially for quick-change spargers, we’re happy to work with you. We’ll use our lab center to perform various characterization and performance tests to ensure your parts, specifically designed as quick-change spargers, are meeting strict specifications.

Computational Fluid Dynamics – If you would like to model your process fluids interaction with your Mott requested part, including quick-change spargers, ask your Mott representative how we can model it using CFD software. This service is essential for understanding the dynamics of gas-liquid interactions facilitated by quick-change spargers and optimizing their performance in your application.

Engineering Memberships – If you’re constantly working on complex designs that require the highest standards of engineering support, including those for applications involving quick-change spargers, ask about our membership rates, which will allow you discounted rates to various lab testing, prototyping, and engineering resources. This support is invaluable for developing and refining solutions that leverage the unique benefits of quick-change spargers.

Enhancing Process Flexibility with Quick Change Spargers

Mott’s quick change spargers are designed to revolutionize gas-liquid mixing processes by offering unparalleled ease of use and efficiency. These spargers allow for rapid replacement and cleaning, minimizing downtime in critical applications such as bioreactors, fermentation tanks, and chemical reactors. The innovative quick change mechanism simplifies maintenance and batch changeovers, making them an ideal solution for industries requiring high purity levels and stringent process controls. By incorporating quick change spargers into their systems, operators can achieve optimal mass transfer rates while ensuring process versatility and reliability.

FAQs: Quick Change Spargers

Q: What are Quick Change Spargers?

A: Quick change spargers are advanced sparging devices designed for easy and fast removal and installation in process systems. They enable efficient gas-to-liquid mixing with the added benefit of rapid changeover capabilities, significantly reducing system downtime during maintenance, cleaning, or batch changes.

Q: How do Quick Change Spargers improve operational efficiency?

A: Quick change spargers improve operational efficiency by allowing for fast and easy sparger replacement without the need for complex tools or prolonged system shutdowns. This feature is particularly beneficial in continuous production environments or where frequent sparger maintenance is required, ensuring minimal interruption to processes.

Q: Can Quick Change Spargers be used in any industry?

A: Yes, quick change spargers are versatile and can be used across various industries, including pharmaceuticals, biotechnology, food and beverage, and chemical processing. Their design is suited for any application that requires gas-liquid mixing and values quick turnaround times for cleaning and batch processing.

Q: Are Quick Change Spargers customizable to specific process requirements?

A: Absolutely, quick change spargers can be customized to meet specific process requirements, including size, materials of construction, and porosity to match the gas flow and bubble size specifications of different applications. This customization ensures that they can be seamlessly integrated into existing systems for optimal performance.

Q: What makes Quick Change Spargers different from traditional spargers?

A: The key difference lies in the quick change feature, which allows for rapid sparger exchange without the need for welding or cutting, unlike traditional fixed spargers. This design significantly reduces maintenance time and effort, enhancing process efficiency and reducing the risk of downtime.

Q: How are Quick Change Spargers maintained?

A: Maintenance of quick change spargers involves simple removal for cleaning or replacement, which can be done quickly and without special tools. Regular inspection and cleaning based on the process media and operating conditions are recommended to ensure long-term reliability and performance.

Inlet Tube sizes are 1/2″ od

Inlet Tube sizes are 1/2″ od