Process Filters, Skids and Elements

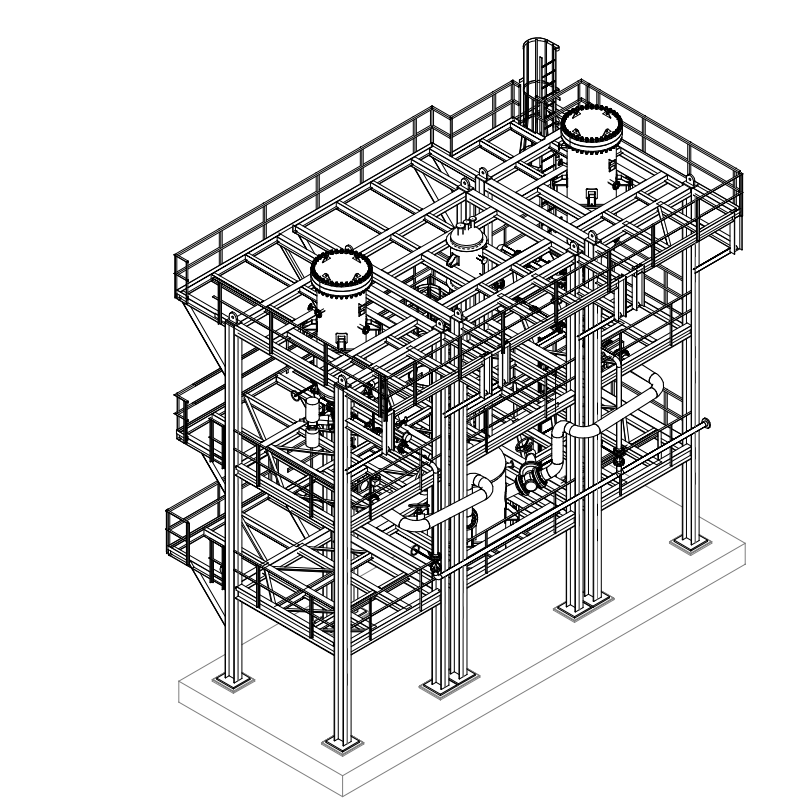

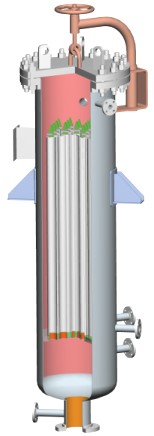

Process filtration systems and skids from Mott are designed to enhance production efficiency, protect investments in expensive equipment, and streamline the installation and maintenance processes typically involved with large-scale operations. Our process filtration systems and filter elements are the ideal solutions for applications facing high-temperature and highly corrosive environments. By utilizing advanced materials and innovative design principles, Mott’s process filtration systems deliver superior durability and performance. They ensure consistent quality and reliability across a wide range of industrial applications, from chemical processing to pharmaceutical manufacturing, where precision and safety are paramount. This makes them an essential component in optimizing operational workflows and maintaining stringent purity standards in challenging conditions.

- Process Filters, Skids and Elements

- Water Reclamation System

- Industrial Filter Cartridges

- High Purity Filters & Components

- Filter Assemblies and Porous Components

- Frit Assemblies and Lab Filters

- Industrial Gas Flow Restrictors

- Industrial Sparger Systems

- Gas Diffusion & Transport Layers

- Flame Arrestor Products

- Sintered Porous Wicks

- 3D Printed Products

- Fluid Process Equipment

- Thermal Management Heat Pipe

- Fluidizers & Snubbers

Advanced Process Filtration Systems by Mott

Mott’s process filtration systems and skids are engineered to meet the stringent demands of various industries requiring high levels of purity and efficiency in their operations. These systems are designed to enhance production efficiency, protect critical equipment, and ensure the highest quality of output by removing contaminants from gases and liquids in high-temperature and highly corrosive environments. Utilizing state-of-the-art materials and technology, Mott’s process filtration systems offer unparalleled reliability and performance, making them an essential solution for sectors such as pharmaceuticals, chemicals, and food and beverage processing. With a focus on innovation, Mott provides customizable filtration solutions that can be tailored to the unique needs of each process, ensuring optimal performance and protection.