Industrial Steam Filters

In processes demanding air filtration, steam sterilization, and venting applications within high-temperature environments, conventional PTFE, PVDF, and polypropylene filters often face significant challenges. Mott’s all-metal 316L SS or Nickel alloy filter cartridges, specifically designed for biotech environments exposed to elevated temperatures and oxidation stress, rise to the occasion. These robust cartridges boast differential pressure capabilities exceeding 250 psid and can operate at temperatures as high as 450°C (842°F). When compared to competing plastic membrane technologies, Mott’s Steam and Vent Filters deliver superior performance, extended service life, and more effective filtration, making them the optimal choice for such critical applications.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Bioreactor vent filtration

- Steam filtration for SIP bioprocessing

- Venting of pressurized air or gas in biopharm processing

Steam & Vent Filters Used in Biotechnology

All-Metal Vent Filters for Pressurized Air or Gases in Extreme Environments

Steam Filters used in Biotechnology

Mott High Purity Steam Filters incorporate sintered porous stainless steel filter media that ensures the effective retention of particles

Filter Feasibility Testing

Filter feasibility testing, application analysis, and information on our testing laboratory for liquid and gas filtration processes.

Product Specs

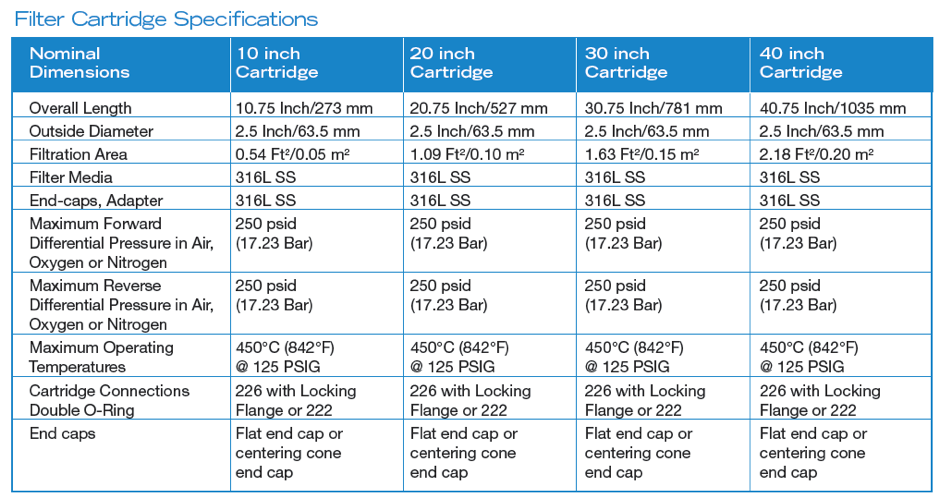

| Specifications |

|

|---|

Videos & Articles

Our Design Capabilities

At Mott, our commitment to delivering comprehensive filtration solutions extends from designing the filter elements to rigorously testing the housing. We take pride in offering a holistic approach to filtration, ensuring that every aspect of your filtration system, including the critical steam filters, is optimized for performance and reliability. Our dedication to excellence extends to validating your filtration solution by conducting thorough tests on samples from your specific process. This validation data ensures that your chosen filtration solution not only meets but exceeds your expectations, providing the utmost confidence in its effectiveness and efficiency.

Relevant Services

Filter Feasibility Testing – Want a recommendation on the correct filter media, alloy, and backwash frequency for your process? Coordinate with a Mott representative to send us a sample of your feed stock to our lab to determine the correct filtration design for your process.

Design Expertise – From start to finish, we customize solutions based on your design parameters – challenge us!

Fluid Modeling – We have built an extensive library of data that increase the accuracy of our flow models to provide initial performance and feasibility estimates prior to building prototypes.

Extensive Partner Network – If a material is not listed or capability not in-house, we maintain an extensive network of partners for new material procurement, advanced manufacturing capabilities, and validation testing.

Engineering Support – Utilize our expert engineers to consult your process and design the right filter to maximize flow and particle capture.

What are Steam Filters?

For those less acquainted with steam filters and their significance, it’s essential to recognize their pivotal role in ensuring the integrity of critical processes. Mott’s Steam Filters are specialized components designed to effectively separate and purify steam in high-temperature environments, such as those encountered in biotech and industrial applications. These filters are constructed from durable materials like 316L stainless steel or Nickel alloys, making them highly resilient to elevated temperatures and oxidation stress. With differential pressure capabilities exceeding 250 psid and the ability to operate at temperatures as high as 450°C (842°F), Mott Steam Filters guarantee superior performance and extended service life, safeguarding processes against contamination and ensuring optimal efficiency.

FAQs: Industrial Steam Filters

Q: What are steam filters, and why are they important?

A: Steam filters are specialized filtration components crucial for maintaining process integrity in applications requiring the purification of steam in high-temperature environments. They play a vital role in separating impurities from steam, ensuring that only clean, contaminant-free steam is used in critical processes, thus safeguarding equipment and product quality.

Q: What makes Mott’s Steam Filters stand out?

A: Mott’s Steam Filters are constructed from robust materials such as 316L stainless steel and Nickel alloys, making them highly resistant to elevated temperatures and oxidation stress. They offer exceptional performance with differential pressure capabilities exceeding 250 psid and can operate at temperatures as high as 450°C (842°F). These features, combined with Mott’s expertise, ensure longer service life and superior filtration performance.

Q: In which industries are steam filters commonly used?

A: Steam filters find extensive use in industries such as biotechnology, pharmaceuticals, and industrial manufacturing. They are essential for processes involving steam sterilization, air filtration, and venting in high-temperature environments, where the purity and quality of steam are critical to maintaining process integrity.

Q: Can Mott provide customized steam filter solutions?

A: Yes, Mott specializes in offering customized steam filter solutions tailored to specific process and application requirements. Our team works closely with clients to design and manufacture steam filters that meet their unique filtration needs and ensure optimal performance in their processes.