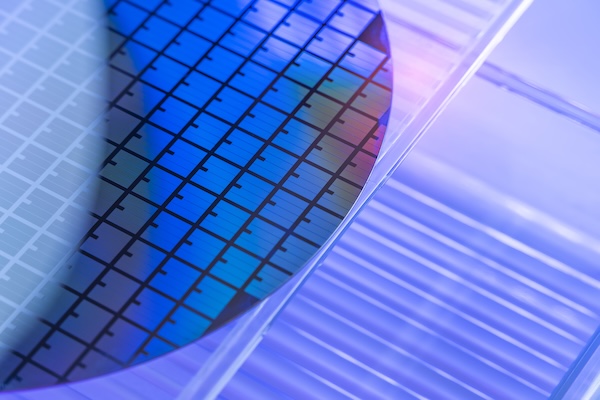

Semiconductor Tools

Mott’s ultra high purity products, essential for the semiconductor industry, include all-metal gas filters and filtration systems designed to support flows ranging from 1-200,000 slpm, crafted from materials like nickel, 316LSS, and Hastelloy®. These components ensure efficient filtration critical for integrated circuit production. Enhancing the lineup of semiconductor tools, Mott also offers gas diffusers, flow restrictors, gas purifiers, and ultra high purity porous ceramics, catering to the nuanced needs of semiconductor manufacturing processes. These tools are pivotal in maintaining the integrity and performance of semiconductor fabrication operations.

Questions? Call 860.747.6333 Today!

The Industry Leader in Filtration and Flow Control Engineering

For over six decades, Mott Corporation has been a pioneer in tackling complex filtration and flow control challenges for major technical brands globally.

With a blend of design mastery and cutting-edge technology, Mott develops highly engineered semiconductor tools tailored to meet specific industry needs.

These products stand out for their unparalleled reliability, quick delivery times, and exceptional value, making Mott a trusted partner in the semiconductor industry and beyond.

Understanding Mott's Semiconductor Tools

Mott Corporation excels in providing advanced semiconductor tools, focusing on high purity filtration and flow control technologies. These products are designed to meet the rigorous standards of the semiconductor manufacturing industry, enhancing efficiency and reliability in processes such as integrated circuit production. With a commitment to innovation, Mott’s solutions support the evolving needs of semiconductor fabrication, ensuring optimal performance and quality in a highly competitive field.

FAQs: Semiconductor Tools

Q: What are semiconductor tools?

A: Semiconductor tools refer to the specialized equipment and technologies used in the fabrication and testing of semiconductor devices, such as integrated circuits. These tools are essential for processes like lithography, etching, deposition, and inspection in chip manufacturing.

Q: Why are advanced semiconductor tools important?

A: Advanced semiconductor tools are crucial for enhancing the precision, efficiency, and scalability of semiconductor manufacturing processes. They enable the production of smaller, faster, and more reliable electronic devices, meeting the growing demands of technology markets.

Q: How do semiconductor tools impact the electronics industry?

A: Semiconductor tools play a pivotal role in the electronics industry by enabling the mass production of integrated circuits found in virtually all electronic devices today. Their advancement directly influences the performance and affordability of consumer electronics, telecommunications, and computing devices.

Q: Can Mott Corporation’s products be considered as semiconductor tools?

A: Yes, Mott Corporation’s products, such as filtration and flow control systems, are integral semiconductor tools in the manufacturing process. They ensure the purity and precision required in semiconductor fabrication, contributing to the overall efficiency and success of semiconductor production.

Our Clients