Gas Diffusion Layers for MEAs

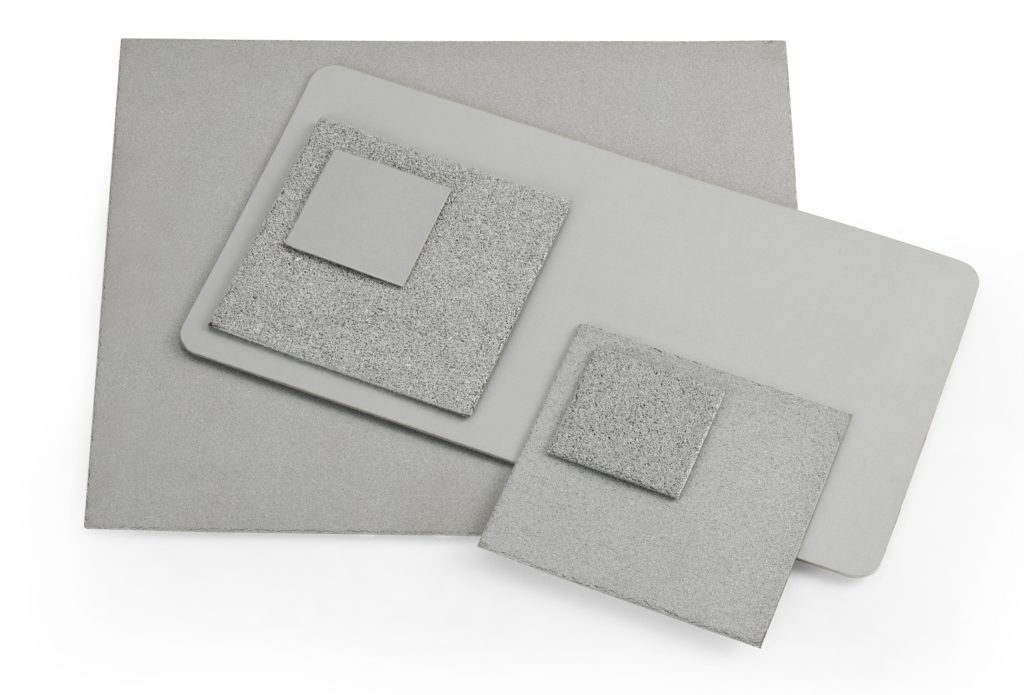

Mott gas diffusion layers are tailored specifically for membrane electrode assemblies, providing you the best performance in terms of mass transport, conductivity, and materials compatibility. Our porous sheet, the key component of the gas diffusion layer, is customized for porosity, thickness, and rigid contact surface to suit your needs. Additionally, Mott has the most extensive material selection in the industry, including titanium for standard applications, nickel 200 and 430 SS for SOFCs, and specialty alloys, such as zirconium/niobium, for aerospace applications.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Hydrogen generation and storage

- Various fuel cell applications

- On-site gas generation

- Gas generation in spacecraft

Gas Diffusion Layers

Overview of various customization options for Mott GDLs

Porous Transport Layer (PTL) Case Study

Mott Porous Transport Layers achieve high power densities in gas generation applications due to a proprietary ultra-thin design resulting in better mass transport in a smaller footprint.

Mott Fuel Cell and Battery Membranes

Learn about Mott capabilities for fuel cell and battery membranes.

Titanium Sheet Quality Standards

Mott Corporation's acceptance criteria for ultra-thin titanium sheet used in various sustainability and alternate energy applications

Product Specs

| Length |

Common Lengths – 10″, 12″, 24″, 40″ Sheet can be laser cut or sheered into smaller pieces if needed. If you need a custom length, please consult factory. |

|---|---|

| Width |

Common Widths – Less than 10” Sheet can be laser cut or sheered smaller if needed. If you need a custom width, please consult factory. |

| Thickness |

Common Thicknesses – .010-.125” (dependent on media grade) Custom lengths available, consult factory |

| Media Grades |

Common Media Grades – .2, .5, 2, 5, 10, 20, 40, 100 Custom media grades available upon request, consult factory |

| Materials |

Common alloys – 316LSS, Titanium, Nickel 200, Hastelloy C-276, Inconel 600 Custom alloys available upon request, consult factory |

| Temperatures |

Alloys with temperature resistance up to 1700 degrees Fahrenheit are available. Custom alloys available to accommodate unique operating temperatures, consult factory |

Understanding Gas Diffusion Layers

A gas diffusion layer is crucial in fuel cell and electrolyzer applications, acting as a bridge for efficient gas transport and facilitating moisture management. It ensures uniform gas delivery across the membrane electrode assembly, optimizing performance and durability. Mott’s advanced gas diffusion layers offer tailored porosity and thickness to meet specific application needs, enhancing the efficiency of energy conversion devices.

Videos & Articles

Our Design Capabilities for Membrane Electrode Assemblies and Gas Diffusion Layers

Application Engineering – Need consultation on your gas diffusion layer or membrane electrode assemblies design? Our team of application engineers are ready to help you determine the right part for your design. With decades of experience working with the world’s largest technical and performance brands, we’re eager to solve complex problems with you.

Customer Innovation Center – We enjoy working with customers on complex projects, especially those involving membrane electrode assemblies. In fact, we’ve dedicated an entire facility to it. Want to join us for various lab testing and engineering consultation sessions? Visit our Customer Innovation Center in Connecticut to develop a solution for your unique application involving gas diffusion layers.

Rapid Prototyping Cell – Trying to determine the feasibility of your membrane electrode assemblies design as fast as possible? Use our rapid prototyping cell to turn around prototypes in as little as 2 weeks. Our engineers will work with equipment similar to our manufacturing facility to provide you with a manufacturable, economical design.

Additive Manufacturing – If you’re looking for the most uniform porosity in a gas diffusion layer or a non-traditional design for membrane electrode assemblies, look no further than working with our porous 3D printing team. We can create controlled porosity designs with various density gradients in non-traditional shapes to satisfy the most unique design request. Our technology allows us to print parts with both solid and porous in a single print cycle.

Relevant Services Gas Diffusion Layers for Membrane Electrode Assemblies

Lab Testing – If you need data packages or feasibility testing for your gas diffusion layer or membrane electrode assemblies part prior to installation, we’re happy to work with you. We’ll use our lab center to perform various characterization and performance tests to ensure your parts are meeting strict specifications.

Computational Fluid Dynamics – If you would like to model your process fluids interaction with a Mott gas diffusion layer or any other Mott part related to membrane electrode assemblies, ask your Mott representative how we can use CFD software.

Engineering Memberships –

If you’re constantly working on complex designs, especially those involving gas diffusion layers and membrane electrode assemblies, that require the highest standards of engineering support, ask about our membership rates. These rates allow you discounted access to various lab testing, prototyping, and engineering resources.

FAQs: Gas Diffusion Layers for Membrane Electrode Assemblies

Q: What is the primary function of a Gas Diffusion Layer (GDL) in Membrane Electrode Assemblies (MEAs)?

A: The primary function of a GDL in MEAs is to facilitate the distribution of reactant gases to the catalyst layer, manage water content, and ensure efficient electron and heat transport. It acts as a bridge between the catalyst layer and the bipolar plates in a fuel cell or electrolyzer.

Q: How does the Gas Diffusion Layer impact the performance of Membrane Electrode Assemblies?

A: The GDL plays a crucial role in ensuring uniform gas distribution, optimal water management, and efficient heat and electron transport. Its properties, such as porosity and thickness, can significantly influence the overall performance, durability, and efficiency of the MEA.

Q: How do I choose the right Gas Diffusion Layer for my Membrane Electrode Assembly?

A: Choosing the right GDL depends on several factors, including the type of fuel cell or electrolyzer, operating conditions, desired performance, and durability requirements. Consult with experts at Mott to provide guidance based on your specific needs.

Q: Can Gas Diffusion Layers be customized for specific applications?

A: Yes, many manufacturers offer customization options for GDLs, including porosity, thickness, hydrophobicity, and other properties. Customized GDLs can be tailored to optimize performance for specific applications or operating conditions.

H3: Q: How do Gas Diffusion Layers manage water in Membrane Electrode Assemblies?

A: GDLs are designed to balance water transport within the MEA. They help in removing excess water produced during the electrochemical reactions while ensuring that the membrane remains hydrated for optimal proton conductivity.