Mott High Purity Bulk and Utility Filters

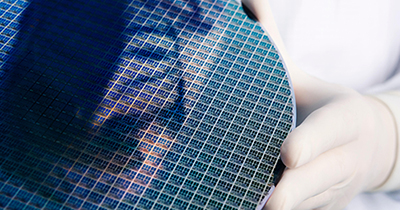

Mott High Purity Bulk and Utility Filters provide 9-log filtration of particles as small as 0.0015 μm, ensuring particle-free gas. These ultra high purity filters are ideally suited for handling the higher temperatures often encountered downstream of a purifier during heated, dry down operations. Our bulk gas filters and housings are engineered to deliver optimal performance and reliability in demanding applications.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

Semiconductor Products Catalog

Explore Mott’s wide range of high purity filters, diffusers and flow restrictors designed exclusively for semiconductor manufacturers.

Product Specs

| Operating Conditions |

» Maximum Operating Pressure: up to 650 psig (44.8 barg) » Maximum Operating Temperature for Inert Gas: up to 450°C » Maximum Differential Pressure: up to 250 psid (17.2 barg) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Materials |

» Hardware: 316L SS » Filter Medium: 316L SS Fiber or Penta® Nickel » Wetted Hardware Surface Finish: 10 Ra » Custom materials also available |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Specifications |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

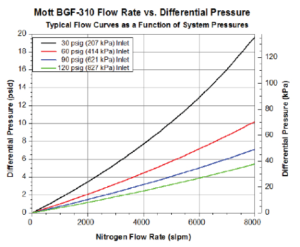

| Flow Data |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

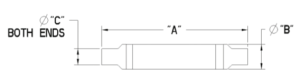

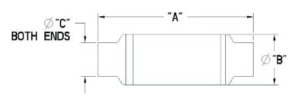

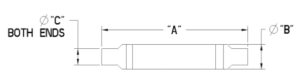

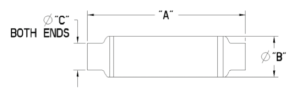

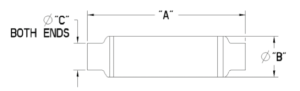

| Fittings & Dimensions |

BGF-310 & BGF-315

BGF-610

BGF-615

BGF-815

BGF12P23

*Custom designs and fittings available. |

Videos & Articles

Our Design Capabilities

- Flow/pressure drop curves and filtration efficiency for virtually any system design

- Gas compatibility considerations

- Custom filter media, pressure vessel, and fitting material and configurations available

Relevant Services

Design Expertise – From start to finish, we customize Mott bulk gas filters based on your design parameters. Challenge us!

Quality Certifications – Need markings for conformity to health, safety, and environmental standards like CE? We’ve got you covered.

Extensive Partner Network – If a bulk gas filter material isn’t listed or a capability isn’t in-house, we have an extensive network of partners for material procurement, advanced manufacturing, and validation testing.

Engineering Support – Our project engineers are on hand to consult about your process and help you select the ideal bulk gas filter for your application.

FAQs: Bulk Gas Filters & Filtration

Q: What is a bulk filter in the context of ultra-high purity applications?

A: A bulk filter is a specialized filtration device designed to handle large volumes of gas, ensuring the removal of contaminants and impurities, especially in ultra-high purity applications like semiconductor manufacturing.

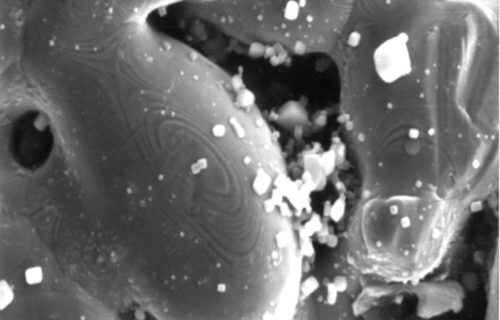

Q: How does Mott’s bulk filter ensure 9-log filtration?

A: Mott’s bulk filters are engineered with advanced porous metal technology, allowing them to achieve 9-log filtration. Mott filters are manufactured to the highest quality and the highest precision porosity in the market. This ensures that the gas passing through is of the highest purity, free from particles and contaminants.

Q: Are Mott’s bulk gas filters compatible with various semiconductor process gases?

A: Yes, Mott’s bulk gas filters are designed to be compatible with all high purity semiconductor process gases, ensuring versatility and reliability in a range of challenging applications. Mott filters are used in the most challenging semiconductor chip manufacturing process, including advanced node technologies < 7nm.

Q: How do Mott’s bulk gas filters contribute to faster “dry down” times?

A: Mott’s bulk gas filters are crafted with materials and designs that allow for quick “dry down,” meaning they achieve optimal performance in minutes rather than hours, reducing downtime and increasing efficiency.

Q: Can Mott’s bulk gas filters handle corrosive gases?

A: Absolutely. Mott’s bulk filters are available in various materials, including Stainless Steel, Hastelloy®, and Penta® Nickel, making them suitable for handling a range of gases, including corrosive ones.

Bulk filters with rated flows up to 170,000 SLPM are available. Consult factory or spec sheets for flow curve information.

Bulk filters with rated flows up to 170,000 SLPM are available. Consult factory or spec sheets for flow curve information.