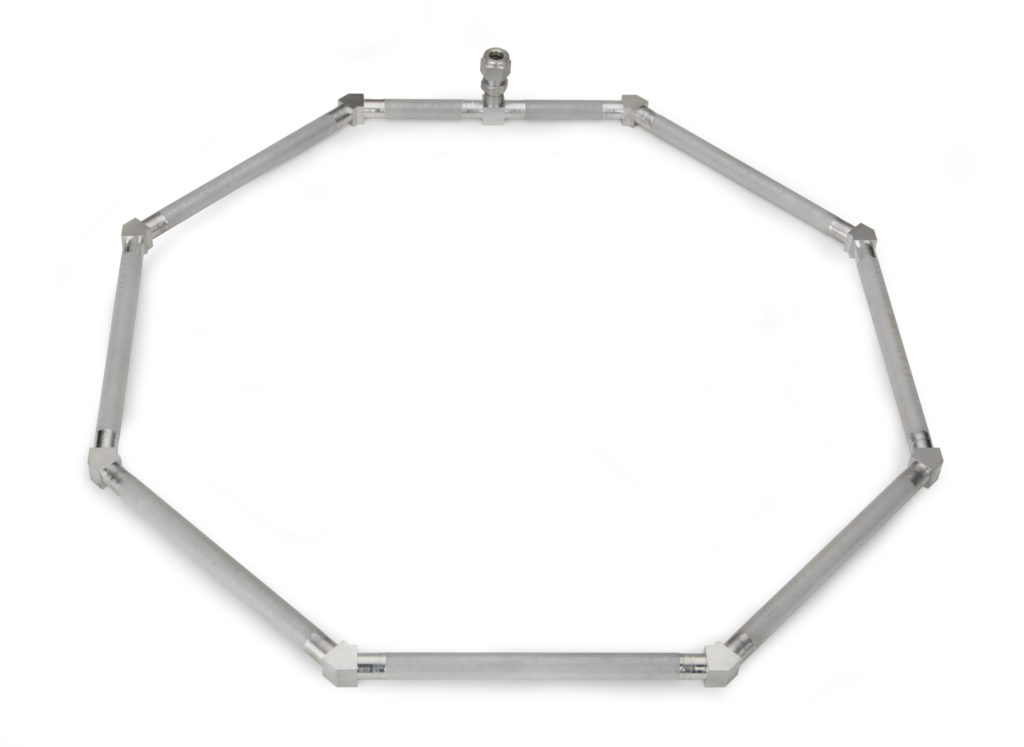

Industrial Sparger Systems

Mott sintered spargers, a key component in efficient gas-liquid contact systems, introduce gases into liquids through thousands of tiny pores, creating bubbles far smaller and more numerous than with drilled pipe and other sparging methods. The utilization of these spargers enhances the gas/liquid contact area significantly, which reduces the time and amount of gas required to successfully dissolve gas into liquid. This efficiency is crucial in various industrial processes, such as fermentation, chemical synthesis, and water treatment, where precise gas dispersion and dissolution are critical. Furthermore, the uniform bubble distribution achieved by Mott spargers leads to more consistent reactions and processes, highlighting their importance in achieving optimal operational efficiency.

- Process Filters, Skids and Elements

- Water Reclamation System

- Industrial Filter Cartridges

- High Purity Filters & Components

- Filter Assemblies and Porous Components

- Frit Assemblies and Lab Filters

- Industrial Gas Flow Restrictors

- Industrial Sparger Systems

- Gas Diffusion & Transport Layers

- Flame Arrestor Products

- Sintered Porous Wicks

- 3D Printed Products

- Fluid Process Equipment

- Thermal Management Heat Pipe

- Fluidizers & Snubbers

Enhancing Process Efficiency with Mott Spargers

Mott spargers are engineered to optimize gas-liquid interactions in various industrial and laboratory processes. By utilizing a porous metal design, these spargers introduce gas into liquids through thousands of tiny pores, producing extremely fine bubbles for increased gas absorption efficiency. This method significantly improves the gas-to-liquid contact area, enhancing the dissolution rate of gases into liquids and ensuring uniform distribution within the medium. Ideal for applications in biotechnology, pharmaceuticals, and environmental engineering, Mott spargers are key to improving process outcomes, efficiency, and cost-effectiveness in operations requiring precise gas dispersion.