Coalescers

At Mott, we offer a full range of liquid-liquid coalescer and gas-liquid coalescer systems for use in various industrial applications to remove particulate matter, water, and other liquids. The CC Series Liquid-Liquid Coalescers are designed to separate two liquid phases with different characteristics of density, viscosity, and interfacial tension (IFT). They efficiently separate liquid-liquid emulsions in oil, gas, and chemical applications extending equipment life. The GLP Series Gas-Liquid Coalescers are designed to remove water, carried over amine aerosols, and fine particulate from process gas, fuel gas, natural gas, methane, hydrogen, and other technical gases. Liquid-liquid coalescers, gas-liquid coalescers, pre-filters, and full systems are available.

Liquid-liquid coalescers and gas-liquid coalescers are used in oil refineries to remove oil and water from hydrocarbon gases. In the refining process, they are placed between the atmospheric distillation column and the vacuum distillation column. Coalescers work by bringing oil and water droplets together, so they may be separated easily. A coalescer air filter is typically used in compressed air systems to remove oil and water vapor from the air. The coalescing filter – made up of a succession of filtering media that combine contaminants to make them easier to separate fluid mixtures – is used to remove contaminants before they can enter the system and cause damage.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Gas-liquid coalescers are used upstream of the deoxidation process in hydrogen generation preventing deactivation. They can also be used upstream of hydrogen compressors reducing water content at the lowest quantity achievable <0.01 ppm. Most often gas-liquid coalescers can be found downstream of the compressor in order to remove oil content from the hydrogen gas stream.

Typical Applications

- FCC/RFCC Refining

- Crude and Vacuum Distillation

- Hydrotreating

- Hydrocracking

- Amine Sweetening

- Petrochemicals – Steam Cracking

- Downstream Oil and Gas Operations

ASCO CC-T Series Liquid-Liquid Coalescers

3.75" and 6"OD Cartridges in Fluoropolymer, Nylon or Polyester Media. The CC-T series coalescing cartridges have been designed to provide high separation efficiencies in those applications where traditional fiberglass cartridges are inefficient.

ASCO CC-M Series Liquid-Liquid Coalescers

2.5" OD Cartridges in Polyester, Polyolefin, or Polyamide Media. The CC-M series coalescing cartridges have been designed to provide high separation efficiencies in those applications where traditional fiberglass cartridges are inefficient.

ASCO LL Systems Liquid-Liquid Coalescers

Liquid-Liquid Coalescers with Cartridge systems - available in vertical and horizontal designs.

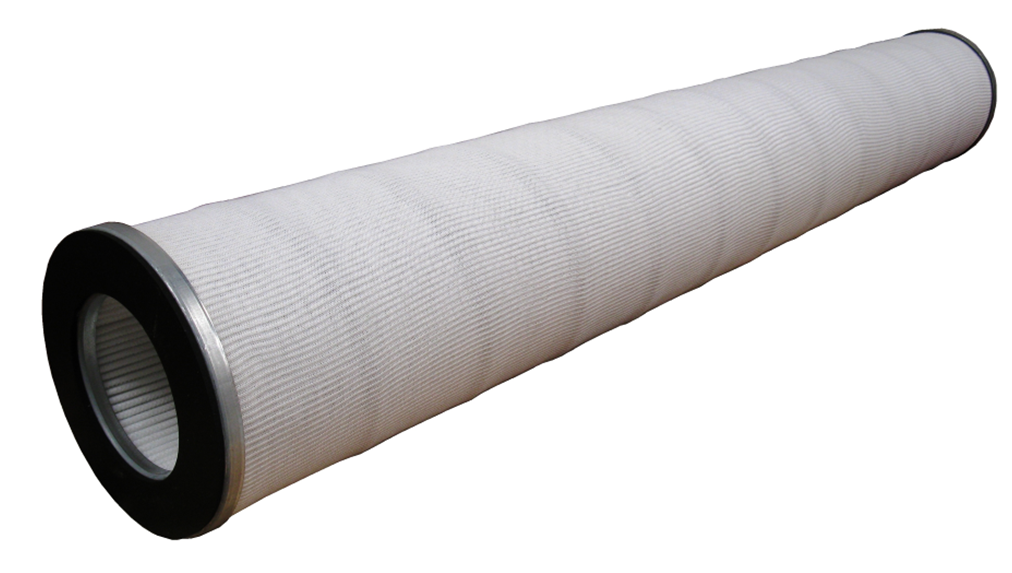

ASCO GLP Series Gas-Liquid Coalescers

The GLP series gas-liquid coalescer elements are manufactured with a series of high performance micro fiberglass, polypropylene, polyester or nylon coalescing media in a pleated configuration optimized for liquid separation.

ASCO LG Systems Liquid-Gas Coalescers

Gas-Liquid Coalescers with Cartridge systems - available in vertical and horizontal designs.

Lab and Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Product Specs

| Dimensions |

Liquid-Liquid Coalescer Filters: Standard Length – 40” Standard Diameters – 3.75” and 6″ Gas-Liquid Coalescer Filters: Standard Length – 36″ and 40” Standard Diameters – 2.75″, 4.5” and 6″ Many Other options are available, consult factory |

|---|---|

| Material Choices |

Liquid-Liquid Coalescer Filters: Coalescing Media – Fluoropolymer, Polyester, Polyolefins, Nylon Support Layers – Cellulose, Polyester, Polypropylene, Nylon External Drain Sleeve – Polyester, Cotton End Caps – Tinned Steel, Stainless Steel, Epoxy Coated Steel Gas-Liquid Coalescer Filters: Coalescing Media – Fiberglass, Polyester, Polypropylene, Nylon Support Layers – Polyester, Polypropylene, Nylon Internal Drain Mesh – Polypropylene External Drain Sock – Polyester, Polypropylene Hardware – Polypropylene + inox core, Tinned Steel, 304 or 316 Stainless Steel Other alloys are available, consult factory |

| Gaskets |

Buna-N, EPDM, Viton Other options available, consult factory |

| Performance |

Liquid-Liquid Coalescer Filters: Disperses phase separation efficiency from 99% to 99.9% Residual water ≤ 15 ppm even with fluids with extremely low IFT, interfacial tension (down to 0.5 dyne/cm) Gas-Liquid Coalescer Filters: Standard media: 99.98% aerosol ≥ 0.3 µm / 99.7% solids ≥ 0.3 µm XA media: 99.994% aerosol ≥ 0.3 µm / 99.98% aerosol ≥ 0.1 µm / 99.98% solids ≥ 0.1 µm Suitable for gas with liquids up to 1000 ppm (0.1%) without demister or vane extractor pre-separation -See product cutsheets for additional product characteristics |

Videos & Articles

Design Capabilities

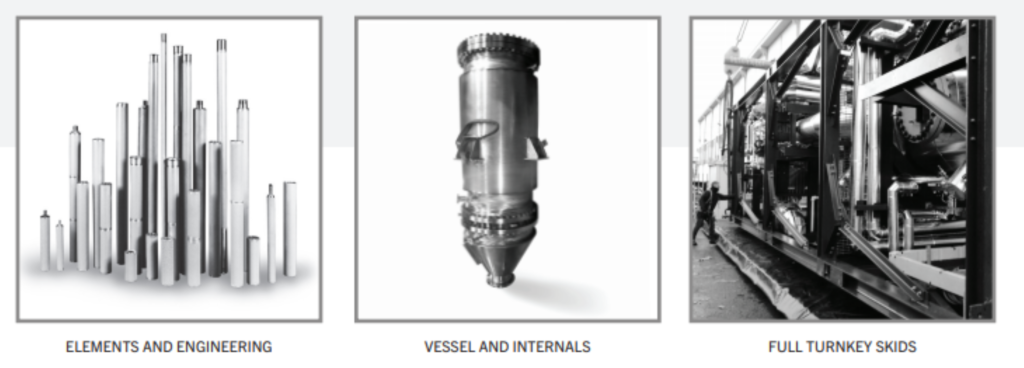

Depending on your needs, Mott can provide just the filter elements, a vessel and elements, or provide you a full turnkey system with the vessel, frame, piping, instruments, and controls for both liquid-liquid coalescer and gas-liquid coalescer applications. Our expertise in designing and manufacturing both liquid-liquid coalescer and gas-liquid coalescer systems ensures that your specific separation and filtration requirements are met with the highest efficiency and reliability. Whether you’re dealing with challenging liquid-liquid emulsions or needing to remove particulates and aerosols from gas streams, Mott’s custom solutions are engineered to optimize your process performance and protect your critical equipment. Our comprehensive approach allows us to tailor each system to the unique operational demands of our clients, ensuring optimal separation efficiency for a wide range of industrial applications.

Relevant Services

Destructive Element Analysis – Send us one of your elements for various analyses to determine the remaining lifetime and filtration efficiency of your filters.

Filter Feasibility Testing – Want a recommendation on the correct filter media, alloy, and backwash frequency for your process? Coordinate with a Mott representative to send a sample of your feed stock to our lab to determine the correct filtration design for your process.

Preventative Maintenance Cycles – Consult with a Mott representative about utilizing a pre-determined lab testing and cleaning schedule to avoid costly downtime.

Engineering Support – Utilize our expert project engineers to design the right filter elements to maximize flow and particle capture.

Optimal Separation with Liquid-Liquid Coalescer and Gas-Liquid Coalescer Systems

Mott specializes in advanced separation solutions, including liquid-liquid coalescer and gas-liquid coalescer systems, designed to meet the stringent requirements of various industrial processes. Our liquid-liquid coalescer systems excel in efficiently separating immiscible liquids, such as oil and water, ensuring high purity levels and process efficiency. Similarly, our gas-liquid coalescer systems are engineered to remove liquids from gas streams, protecting critical equipment and ensuring the quality of the final gas product. Utilizing state-of-the-art materials and innovative designs, Mott’s coalescers provide reliable, high-performance separation capabilities that can be customized to the specific needs of our clients, making them invaluable in industries ranging from oil and gas to chemical processing and beyond.

FAQs: Liquid liquid coalescers & gas liquid coalescers

Q: What is a liquid-liquid coalescer?

A: A liquid-liquid coalescer is a filtration device designed to separate two immiscible liquid phases, such as oil and water, by coalescing smaller droplets into larger ones, which then separate more easily due to differences in density. These systems are vital in processes where precise separation of liquids is crucial for product quality and process efficiency.

Q: What is a gas-liquid coalescer?

A: A gas-liquid coalescer is designed to remove liquid droplets from gas streams, such as water or oil aerosols from natural gas. By coalescing fine liquid particles into larger droplets, they can be separated from the gas flow, protecting downstream equipment and ensuring the purity of the gas product.

Q: How do liquid-liquid coalescers and gas-liquid coalescers work?

A: Both types of coalescers use a combination of physical media to trap fine droplets of the dispersed phase (liquid in gas or one liquid in another) and merge them into larger droplets. Once the droplets are sufficiently large, gravity or centrifugal force separates them from the continuous phase, resulting in two distinct phases for liquids or a dry gas stream.

Q: What are the typical applications for liquid-liquid coalescers and gas-liquid coalescers?

A: Liquid-liquid coalescers are commonly used in the oil and gas industry for water-oil separation, in chemical manufacturing, and in any process requiring the separation of two immiscible liquids. Gas-liquid coalescers are essential in natural gas processing, petrochemical production, air compression systems, and other applications where moisture or liquid aerosols need to be removed from gas streams.

Q: Can liquid-liquid coalescers and gas-liquid coalescers handle high flow rates?

A: Yes, both liquid-liquid coalescers and gas-liquid coalescers are designed to accommodate a wide range of flow rates. The specific capacity of a coalescer system depends on its design, the properties of the fluids being processed, and the desired purity levels. Customization options are available to match the coalescer system to the specific requirements of the application.

Q: Are there different types of media used in liquid-liquid and gas-liquid coalescers?

A: Yes, the media used in coalescers can vary widely depending on the application’s specific requirements, including the type of liquids or gases being separated, the presence of contaminants, and the desired efficiency. Options range from fibrous materials to porous metallic media, each offering distinct advantages in terms of separation efficiency, pressure drop, and resistance to fouling.

Q: How are liquid-liquid coalescers and gas-liquid coalescers maintained?

A: Maintenance involves regular inspection, cleaning, and replacement of the coalescing media or elements. The frequency and type of maintenance depend on the nature of the fluids being processed and the operating conditions. Proper maintenance is crucial to ensure the long-term efficiency and reliability of the coalescer system.