Porous Metal Fluidizers

Porous metal stands out as the perfect material for fluidizing granulated solids or heavy materials for transport, making it a versatile fluidizer. When gas is passed through the porous metal media, it induces a distributed fluidizing effect on the combined material, creating hydraulic behavior akin to that of a liquid. This unique capability enables the seamless and efficient transport of the combined material to its intended destination, making porous metal fluidizers an essential component in various industrial processes.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Fluid transportation

Porous Metal Overview

Check out the features and benefits of Mott sintered porous metal media that delivers uniform porosity for superb filtration efficiency and structural integrity.

Explore Mott’s Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Lab and Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Product Specs

| Design Considerations |

Engineers run into design challenges every day and we help overcome them. Consider some of the below design characteristics when engineering a custom filtration or flow control product: – Flow Rate – Hone in on the exact flow your product needs – Process Temperature – Go high (1500F+) or low (cryogenic), our products can handle it – Pressure Drop – Minimize system efficiency loss – System Pressure – High operating pressures are frequently designed for Corrosive effects, if any – design for highly corrosive gases or liquid with unique metal material options – Cleanliness Requirements – Check out Cleanliness and Treatment Options in this section – Operating Fluid – Such as type, density, viscosity |

|---|---|

| Physical Dimensions |

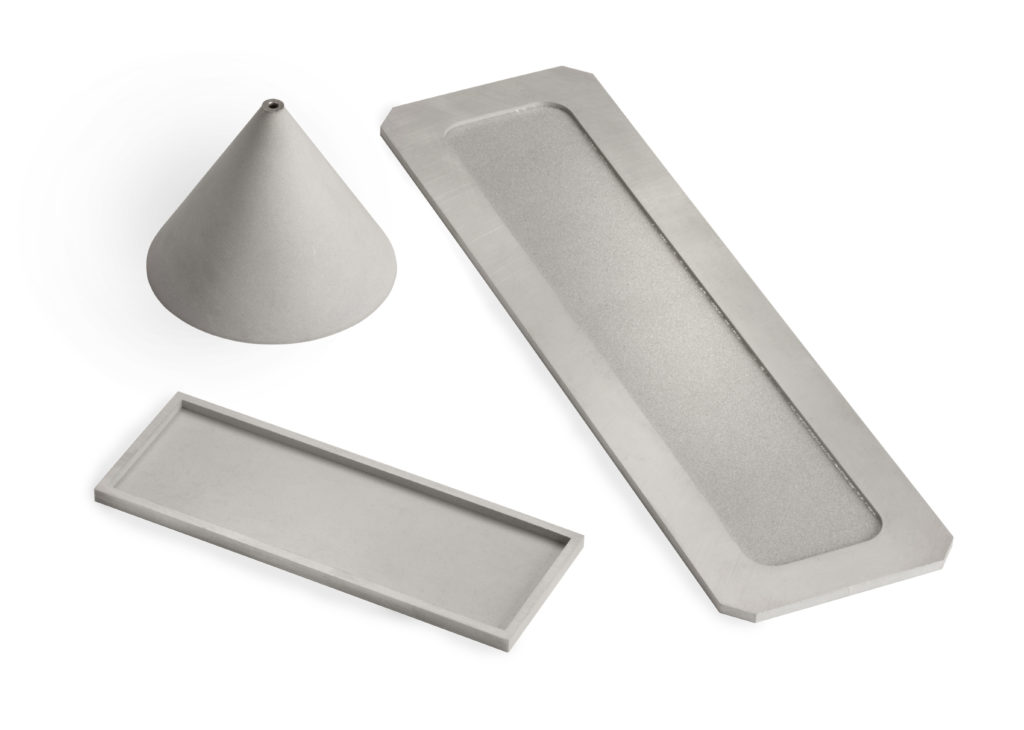

We make products from extremely small drug implants and building size filtration systems. Custom designing our products to fit into your product or process is what we do. See a starting list of porous metal product geometry. Our customers often require a integration into hardware and housings – we do that, too. Forming, machining, brazing, and welding are just some of the capabilities we use to customize dimensions or integrate our product to hardware connections. General starter geometries: – Disc – Sheet – Cup – Bushing – Tube – And more – contact us! |

| Performance Characteristics |

Optimizing performance lets our customers bring the best product to market. Benefits include improved yields and processing efficiency, faster instrument response times, and better quality product produced. Our design teams will translate your desired product specifications and process needs to maximize your capabilities. Just some of the custom performance capabilities are listed below: – Flow Permeability – Particle Size Retention – Surface Characteristics – Mean Pore Size – Density – Capillary Attraction – Mechanical Properties – Thermal Conductivity |

| Material Choices |

Our customers may choose from an extensive list of material options to meet the specifications of their product application. We even source new materials through our supply chain for some of the most extreme technology advancements. Below are just some of the options available: – Stainless Steel; 316L, 304L, 310, 347 and 430 – Hastelloy® C-276, C-22, X, N, B and B2 – Inconel ® 600, 625 and 690 Nickel 200 and Monel ® 400 (70 Ni-30 Cu) – Titanium Alloy 20 – Many others – Contact us |

| Hardware Connections |

A virtually infinite combination of hardware connections are available for design. We are capable of sourcing and assembling the connection you desire using years of experience and special equipment. For example, welding porous metal products is significantly different than solid to solid. If done improperly, blowouts can occur or leak paths can form if done improperly, causing waste and poor performance. Additionally, when assembling porous metal media into products, surface damage can occur which will dramatically impact the products performance. We’re experienced in all types of welding an assembly, use our manufacturing capability to your advantage. |

| Cleanliness & Treatment |

Mission critical applications often require a host of unique properties and desired levels of cleanliness. Take advantage of our organic free processes and our Class 100 (ISO 5) and Class 10,000 (ISO 7) clean room manufacturing capabilities if your product and industry demands top cleanliness. In addition, post-treatments can be used to achieve additional performance characteristics, such as hydrophobic properties or additional strength. Some of these capabilities include: – Annealing – ensure the best mechanical strength and corrosion resistant properties – Surface Coatings – coatings such as silicone are used to achieve added properties – Chemical Treatments – special chemical treatments such as surfactant treating add surface characteristics – Passivation – get iron free cleanliness with nitric acid passivation straight out of the ASTM – Organic Free Processing – let your product follow a unique process separate from regular production – Advanced Joining – use our welding capability for oxidation free product – Certified Oxygen Service |

| Specifications and Quality |

High regulated and specialized industries require significant quality reviews, process documentation, and inspection and test plans. Experienced with medical, pharmaceutical, automotive, aerospace, nuclear, and other industries, we are ready to handle complex quality reporting requirements. Our customers often have specific agency approvals and tests and request specific sampling plans – send them our way. Here are a few examples of what we handle: – Quality Reports and First Article Inspections – Material Certification – PPAP – ATEX Directive – Certificate of Conformance – Sample Sizes and Statistical Process Control – Custom Inspection Requirements In addition, our engineering teams have years of experience with the latest design specifications of industries like semiconductor, medical, and aerospace. Save time and effort by using their knowledge of filtration and flow control applications by having them design with you. |

| Logistics Options |

Packaging and shipping needs should be considered with the design process as many options are available. For example, certain industries require very specific bagging requirements to minimize particle contribution and utilize nylon or barefoot bags vice polymer. Getting the parts when you want them is important to us. We offer shipping and inventory solution services, including: – Expedited Shipments – KanBan Inventories – Portal Management Check out the Logistics section of our Services page. |

Videos & Articles

Design Capabilities

Application Engineering – Need consultation on your fluidizer design? Our team of application engineers is ready to assist you in determining the right fluidizer part for your specific application. With decades of experience collaborating with the world’s largest technical and performance brands, we’re enthusiastic about solving complex challenges in fluidizing with you.

Customer Innovation Center – We thrive on collaborating with customers on intricate projects, and we’ve dedicated an entire facility to it. Interested in participating in lab testing and engineering consultation sessions? Visit our Customer Innovation Center in Connecticut to develop a fluidizer solution tailored to your unique application.

Rapid Prototyping Cell – Are you trying to assess the feasibility of your fluidizer design as quickly as possible? Utilize our rapid prototyping cell to expedite the production of prototypes in as little as 2 weeks. Our engineers employ equipment similar to our manufacturing facility to deliver a manufacturable and cost-effective fluidizer design.

Additive Manufacturing – If you’re in search of the most uniform porosity or a non-traditional fluidizer design, look no further than collaborating with our porous 3D printing team. We can create controlled porosity designs with various density gradients in unconventional shapes, addressing even the most unique fluidizer design requests. Our technology allows us to print parts with both solid and porous features in a single print cycle.

Relevant Services

Lab Testing – If you need data packages or feasibility testing for your fluidizer part prior to installation, we’re happy to work with you. We’ll use our lab center to perform various characterization and performance tests to ensure your fluidizer parts are meeting strict specifications.

Computational Fluid Dynamics – If you would like to model your process fluids’ interaction with a Mott fluidizer part, ask your Mott representative how we can use CFD software to provide valuable insights and optimizations.

Engineering Memberships – If you’re consistently working on complex fluidizer designs that demand the highest standards of engineering support, ask about our membership rates. These memberships offer you discounted access to a wide range of lab testing, prototyping, and engineering resources to facilitate your fluidizer projects.

What are fluidizers?

Mott’s fluidizers are innovative devices designed to enhance material handling processes across various industries. These fluidizers utilize the unique properties of porous materials to optimize the transport and flow of granulated solids and heavy materials. By inducing hydraulic behavior similar to that of a liquid, Mott’s fluidizers ensure efficient and consistent material transfer, making them indispensable tools in pharmaceuticals, food processing, and chemical manufacturing. With the strength, durability, and chemical compatibility of porous metal technology, Mott’s fluidizers redefine precision and efficiency in material handling, ultimately elevating the performance of industrial processes.

FAQs: Fluidizers

Q: What is a fluidizer?

A: A fluidizer is a specialized device used in various industries to optimize the transport and flow of materials, especially granulated solids or heavy materials. It utilizes porous materials to induce hydraulic behavior similar to that of a liquid, enabling efficient material handling.

Q: Where are fluidizers commonly used?

A: Fluidizers find common applications in industries such as pharmaceuticals, food processing, and chemical manufacturing, where efficient material transfer and transport are essential. They are employed to ensure smooth and consistent flow of materials in various processes.

Q: How do fluidizers work?

A: Fluidizers work by passing gas through porous materials, creating a distributed fluidizing effect on the combined material. This induces hydraulic behavior similar to that of a liquid, allowing for easy and efficient transport of the material to its intended destination.

Q: What are the benefits of using Mott’s fluidizers?

A: Mott’s fluidizers are designed with porous metal technology, offering advantages such as strength, high-temperature tolerance, durability, and chemical compatibility. They play a crucial role in improving material transfer efficiency and reliability in various industrial processes, making them a preferred choice for industries demanding precision and performance.