3D Printed Products

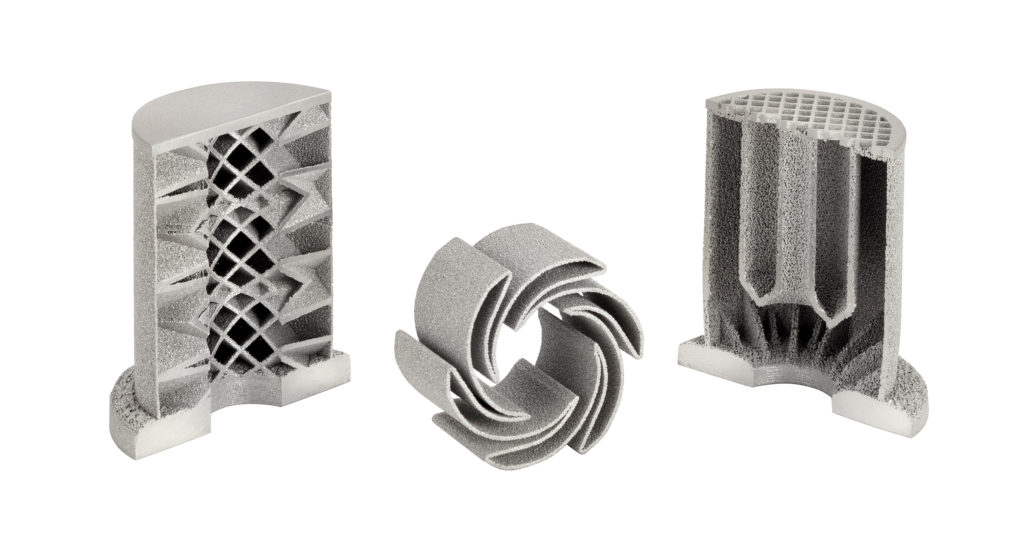

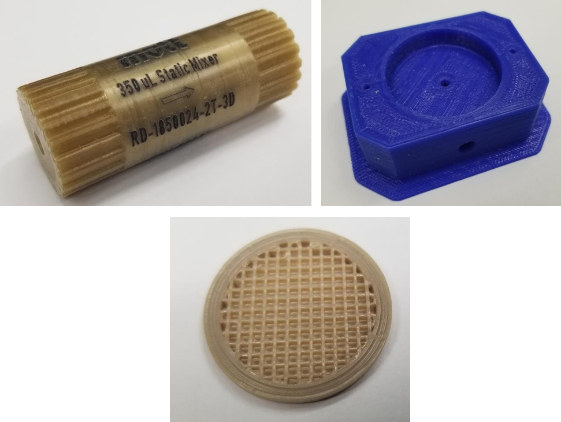

Unlock the endless possibilities of advanced manufacturing with our state-of-the-art controlled-porosity 3D printing technology, specializing in 3D printing porous materials. Whether you’re in aerospace, automotive, medical devices, or any other industry, our innovative approach allows you to achieve functional advantages and design freedom that were once thought impossible.

With Mott Corporation’s cutting-edge 3D printing porous materials technology, you can go beyond traditional manufacturing constraints. Imagine creating finished assemblies that seamlessly blend solid hardware, gradient structures, and intricately designed porous features—all within a single, efficient print. This means you can enhance fluid flow control, optimize filtration, and create lightweight yet robust components, all while streamlining your production processes and reducing costs. Welcome to the future of manufacturing, where possibilities are limited only by your imagination.

- Process Filters, Skids and Elements

- Water Reclamation System

- Industrial Filter Cartridges

- High Purity Filters & Components

- Filter Assemblies and Porous Components

- Frit Assemblies and Lab Filters

- Industrial Gas Flow Restrictors

- Industrial Sparger Systems

- Gas Diffusion & Transport Layers

- Flame Arrestor Products

- Sintered Porous Wicks

- 3D Printed Products

- Fluid Process Equipment

- Thermal Management Heat Pipe

- Fluidizers & Snubbers

What are 3D Printed Porous Materials?

Are you new to the world of 3D printing porous materials? At Mott Corporation, we specialize in harnessing the power of this cutting-edge technology to create components with controlled porosity.

Porous materials enable precise control over fluid flow, filtration, heat exchange, and more. Our advanced approach to 3D printing porous materials allows for the creation of complex, multifunctional parts that were once challenging to manufacture.

Whether you’re seeking lightweight yet sturdy structures or innovative designs with optimized performance, our expertise in this field can revolutionize your production processes and open up a world of possibilities.

FAQs: 3D Printed Porous Materials

Q: What are 3D printed porous materials?

A: 3D printed porous materials are objects created using 3D printing technology with controlled porosity. This means that these materials have intentionally designed voids or pores within them, allowing for precise control over properties like fluid flow, heat exchange, and filtration. They are widely used in various industries for their unique properties and applications.

Q: What are the advantages of using 3D printed porous materials?

A: There are several advantages to using 3D printed porous materials. These include the ability to customize porosity for specific functions, lightweight yet robust structures, enhanced fluid management, improved heat transfer, and the creation of complex, multifunctional components. Additionally, 3D printing allows for design freedom and the consolidation of multiple manufacturing steps into one process, saving time and costs.

Q: In which industries are 3D printed porous materials commonly used?

A: 3D printed porous materials find applications in a wide range of industries. These include aerospace, automotive, medical devices, filtration systems, oil and gas, microelectronics, and more. Their versatility and ability to meet specific requirements make them valuable in various sectors.

Q: How can I incorporate 3D printed porous materials into my projects?

A: To incorporate 3D printed porous materials into your projects, you can work with specialized companies or facilities equipped with advanced 3D printing technology. They can assist in designing and manufacturing components tailored to your specific needs. Additionally, you can explore the vast potential of these materials in enhancing fluid flow control, filtration, heat management, and other areas relevant to your industry.