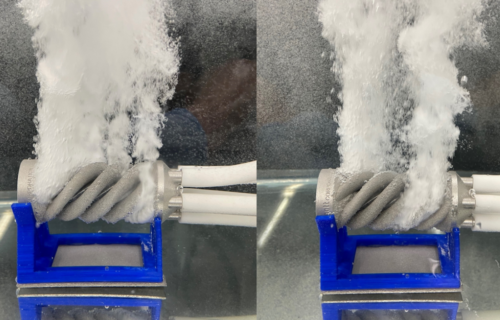

Breaking the Bottleneck: How Mott’s 3D-Printed Impeller is Revolutionizing Perfusion Filtration

In a world where higher throughput and cleaner performance are non-negotiable, traditional filtration methods are starting to hit their limits. […]

Tackling Agricultural Wastewater at Scale: A New Approach for Dairy Operations

To read the full story, visit the Hartford Business Journal. Transforming Dairy Wastewater Treatment with Advanced Filtration Technology Wastewater management […]

How Filtration is Powering the Next Wave of Semiconductor Innovation: Moly Metal, ALD, and the Rise of More-than-Moore

Want the full story? Read the full article on Filtration + Separation here. The semiconductor industry has long lived by […]

It’s Not Rocket Science, Except When It Is: Solving Spacecraft Propulsion Challenges

Space exploration demands precision engineering, and the slightest oversight can lead to significant issues. In a recent next-gen spacecraft project, […]

Are You Ahead of the Rising Demand for Needle Coke?

The needle coke market is experiencing an unprecedented surge, driven by the rapid expansion of electric vehicles (EVs) and the […]

The Next Wave of Semiconductor Growth: High-Purity Gas Filtration

The semiconductor industry is undergoing a rapid transformation, driven by advancements in AI, high-performance computing (HPC), automotive electronics, and IoT […]

Advanced Thermal Management in Semiconductor Tools: Improving Waste Heat Recovery and Mirror Deformation

By Karthik Viswanathan, Vice President & General Manager, Mott Corporation Increased demand for data centers and artificial intelligence is driving […]

How Ancillary Technologies Are Elevating the Healthcare Industry

Ancillary technologies and medical devices are indispensable in modern healthcare, supporting doctors and nurses by enhancing patient care and operational […]

Advancements in Electrolyzer Technology Could Make Green Hydrogen Viable Sooner Than You Think

Historically, the mass production of green hydrogen has not been seen as a viable alternative energy solution for our climate […]