Polyol and Resins

Mott has been a trusted partner for polyol and resins manufacturers, dedicated to optimizing their operational efficiency over the years. Our extensive experience in working with polyol and resins manufacturers involves addressing various challenges, such as the removal of residual catalysts, salts, and solidified or burnt products from the production stream. Mott’s HyPulse filters are engineered to withstand high process temperatures, reaching up to 1700°F with materials like Hastelloy® X. This not only ensures the maintenance of low fluid viscosity but also eliminates the need for heat exchangers to cool the material before filtration. With Mott’s filtration solutions, you can expect typical solids loading to be less than 5 wt.% solids, with an impressive 99+% capture rate of particles down to submicron sizes. Our commitment to polyol and resins manufacturers is geared towards enhancing the efficiency and reliability of their production processes.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Polyol Manufacturing

- Resin Manufacturing

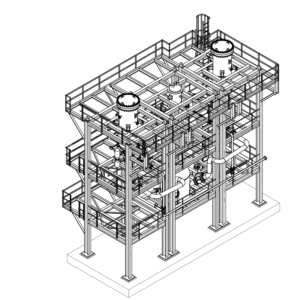

Process Systems Overview

A comprehensive overview of Mott's offerings for process filtration applications.

Elements

Explore the features and benefits of Mott sintered porous metal media for superb filtration efficiency, structural integrity and uniform porosity.

Mott Design Process

We take a scientific approach to filtration system design to not only ensure your project stays on time and on budget, but also to ensure it operates at peak efficiency.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Hastelloy is a trademark of Haynes International, Inc.

Mott's Filtration Solutions for Polyol and Resins Manufacturers

For those less familiar with our offerings, Mott provides specialized filtration solutions tailored to the unique needs of polyol and resins manufacturers. Our expertise spans decades in assisting manufacturers in achieving peak operational efficiency. We excel in addressing challenges such as the removal of residual catalysts, salts, and solidified or burnt products from production streams. With Mott’s advanced HyPulse filters, engineered to withstand high process temperatures, we help polyol and resins manufacturers optimize their production processes, ensuring consistent and reliable results.

FAQs: Polyol and Resins Manufacturing

Q: What is Polyol and Resins Manufacturing?

A: Polyol and resins manufacturing refers to the industrial process of producing chemical compounds known as polyols and resins. Polyols are commonly used in the production of polyurethanes, while resins serve as essential components in various industries, including adhesives, coatings, and plastics.

Q: What are the key challenges in Polyol and Resins Manufacturing?

A: Polyol and resins manufacturing can pose challenges related to maintaining product quality. These challenges include the removal of residual catalysts, salts, and solidified or burnt materials from the production process. Effective filtration and purification methods are essential to ensure the final products meet stringent quality standards.

Q: How can Mott assist in Polyol and Resins Manufacturing?

A: Mott specializes in providing advanced filtration solutions tailored to the specific needs of polyol and resins manufacturing. Our expertise in filtration technology, including HyPulse filters, helps manufacturers optimize their production processes, enhance operational efficiency, and ensure consistent product quality. We play a vital role in minimizing contaminants and maximizing filtration efficiency, contributing to improved manufacturing outcomes and product quality.

Q: What is the significance of filtration in Polyol and Resins Manufacturing?

A: Filtration is of utmost importance in polyol and resins manufacturing as it helps remove impurities, residual catalysts, and unwanted particles from the production process. This ensures the final products meet the desired quality standards and specifications.

Q: How does Mott’s filtration technology benefit Polyol and Resins Manufacturing?

A: Mott’s filtration technology, including HyPulse filters, offers precise and efficient solutions for polyol and resins manufacturers. It aids in maintaining high product quality by effectively removing contaminants, optimizing production processes, and enhancing overall operational efficiency.

Q: Are Mott’s filtration solutions customizable for specific Polyol and Resins Manufacturing needs?

A: Yes, Mott provides customizable filtration solutions tailored to the unique requirements of polyol and resins manufacturers. Our filtration systems and HyPulse filters can be configured to address specific challenges, ensuring optimal results and product quality in the manufacturing process.