Categories

It’s Not Rocket Science, Except When It Is: Solving Spacecraft Propulsion Challenges

Space Launch System Takes Off. 3D Scene.

Space exploration demands precision engineering, and the slightest oversight can lead to significant issues. In a recent next-gen spacecraft project, a propulsion engineer discovered a critical design flaw that threatened the integrity of data received from the spacecraft post-launch. This issue revolved around the use of a regular orifice restrictor for nitrogen flow through instrumentation to purge unwanted gases. On the surface, this seems straightforward, but the reality was far more complex.

The Problem with Supersonic Flow in Spacecraft Propulsion

When nitrogen gas flows through a small orifice at supersonic speeds, it generates noise levels that can cause vibrations. These vibrations are particularly problematic for sensitive equipment onboard spacecraft. Once the spacecraft is in space, accessing and repairing these components is nearly impossible. Therefore, ensuring that all equipment functions correctly without interference from vibrations is crucial for successful data collection and mission success.

The Importance of Noise Reduction in Spaceship Propulsion

Noise and vibrations caused by supersonic gas flow can severely impact the performance of critical spacecraft instruments. Inaccurate data collection due to equipment vibrations can jeopardize entire missions, leading to significant financial and operational losses. Addressing these issues during the design phase is essential to avoid complications once the spacecraft is in orbit.

A Creative Porous Metal Solution

Fortunately, the company found a solution in Mott’s porous metal flow restrictors, which were already being used in a subassembly of the spacecraft. These flow restrictors offered a way to mitigate the noise and vibrations caused by supersonic gas flow. By running gas through the porous metal restrictor, the vibrations were significantly reduced, allowing the critical parts to function properly under the extreme conditions of space.

How Porous Metal Restrictors Work

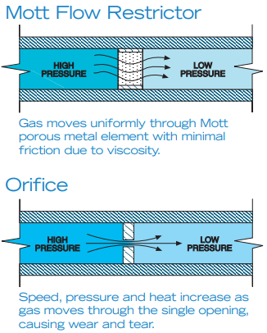

Mott’s porous metal restrictors operate by maintaining an even distribution of gas flow through multiple pores uniformly over the entire surface. This design ensures that there is no acceleration of gases, effectively eliminating the noise typically associated with supersonic flow. This uniform flow distribution is vital for preventing the creation of disruptive vibrations.

Customizing Solutions for Spacecraft Propulsion

One of the key advantages of working with Mott is the ability to customize flow restrictors to meet specific requirements. In this case, Mott’s engineers calibrated the restrictors to match the specified gas type and flow rate needed for the spacecraft. This tailored approach ensured that the propulsion system functioned optimally without causing interference with other critical systems.

The Impact of Precision Engineering in Space Exploration

Without the precision and reliability of Mott’s customized flow restrictors, the company would have faced significant challenges after the spacecraft’s launch. The ability to reduce noise and vibrations not only preserved the integrity of the data collected but also ensured the overall success of the mission. This example highlights the importance of detailed engineering solutions in the high-stakes environment of space exploration.

Learn More About Mott’s Spacecraft Propulsion Solutions

Mott’s expertise in developing customized solutions for spacecraft propulsion systems is invaluable for companies involved in space exploration. Their advanced porous metal technology provides reliable and efficient performance under the most demanding conditions.

Contact Us for More Information

Interested in learning more about how Mott’s solutions can enhance your spacecraft propulsion systems? Contact us today, and our team of experts will be in touch with more information on how we can help you achieve your mission objectives with precision and reliability.