Microfiltration / Ultrafiltration Systems

Leading the Way in Water Treatment with Microfiltration and Ultrafiltration Systems

Microfiltration and Ultrafiltration systems incorporating advanced sintered alloy filter element technology, are designed to tackle the most challenging wastewater treatment applications. These systems efficiently separate solids from liquids, offering a sustainable solution for industries looking to improve their waste management processes. With durable construction and high-efficiency filtration capabilities (media grades 0.5, 0.25, and 0.025), these systems stand out as robust solutions for achieving superior water purity.

Questions? Call 860.747.6333 Today!

Stainless Steel Microfiltration & Ultrafiltration Systems

- Porous stainless-steel tubular membranes (3/4” ID) with an internal titanium dioxide coating (0.02 micron average pore size).

- Welded and bolted construction adhering to ASME code-stamped pressure vessel standards.

- Available in lengths of 5′, 10′, and 20′ with flexibility in diameter.

- Membranes boast a remarkable lifespan of over 10 years, even in challenging applications, requiring minimal downtime, maintenance, or repair.

- A simple, robust system with no internal moving parts, featuring an efficient externally mounted pump.

- Offers flexibility and tunability, operating in both batch-mode and continuous mode, and can be mounted horizontally or vertically.

- Minimal pre-filtration required for effective operation.

- Proudly manufactured in the USA, ensuring top-quality performance and reliability for your filtration needs.

Tube

Tube Module

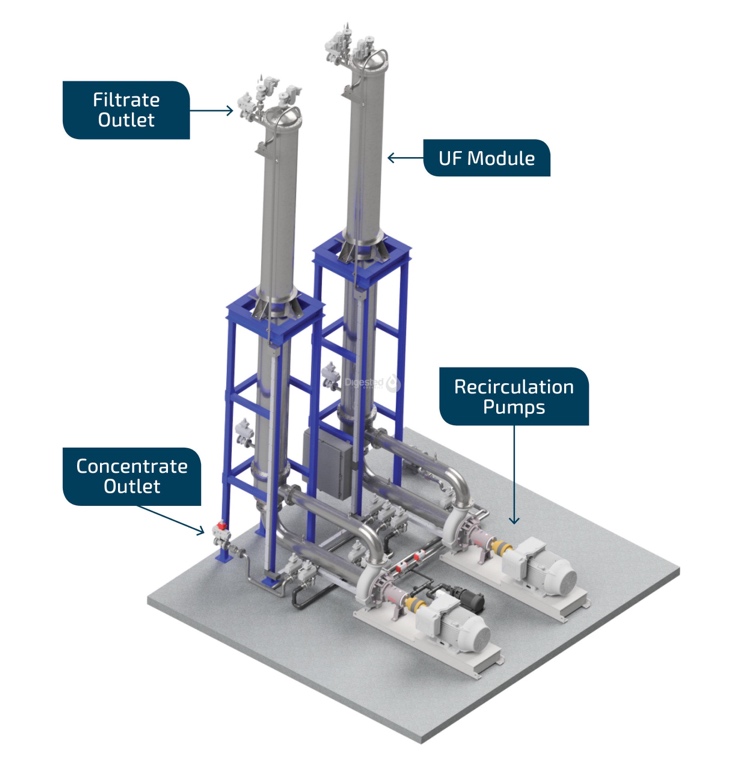

Large vertical UF project for manure digestate being installed in Wisconsin, 2023

Polymeric Ultrafiltration (pUF)

- Our pUF consists of a unique PVDF membrane chemistry, energy-saving module design, and patented closed-loop operating protocol for achieving high permeate recoveries.

- Our pUF performs in high strength, high solids wastewater treatment or thickening applications, providing UF quality effluent (0.04 micron pore size) with minimal energy consumption.

- Our pUF is the world’s only outside-in crossflow UF membrane filtration technology for high strength and high solids wastewater.

Our Parallel Channel PVDF Module

- Outside-in permeation occurs in parallel channels

- The required crossflow velocity to achieve high flux rates is 2-10x less than tubular membranes, resulting in dramatic energy savings

- High membrane packing density (385 ft2 in a 10” x 10’ module)

- Up to 20 psi backwashing capability to maintain peak performance

- Systems are designed to run continuously in a feed and bleed configuration or with internal concentrate thickening in a repeat batch configuration

- Typical electrical consumption: 2.5-3.0 kwh/1,000 gal of permeate

Applications

- Food and Beverage

- Food Waste

- Stillage Filtration

- Agriculture

- Landfills

- Wastewater Filtration

Videos & Articles

What are Microfiltration & Ultrafiltration Systems?

Mott’s Microfiltration & Ultrafiltration Systems stand as a testament to advanced filtration solutions. Utilizing state-of-the-art porous stainless-steel tubular membranes with a titanium dioxide coating, our systems offer exceptional filtration capabilities. With a lifespan of over a decade in challenging applications and minimal maintenance requirements, Mott’s Microfiltration & Ultrafiltration Systems redefine the standards of longevity and reliability. Explore how our innovative technology can elevate your filtration processes, delivering cleaner and more efficient results in diverse industries and applications.

FAQs: Microfiltration & Ultrafiltration Systems

Q: What are Microfiltration & Ultrafiltration Systems?

A: Microfiltration & Ultrafiltration Systems are advanced filtration technologies designed to remove suspended solids, particulates, and contaminants from liquids using ultrafine membranes. These systems provide efficient clarification and concentration of various fluids, making them essential in wastewater treatment, industrial processes, and more.

Q: How do Microfiltration & Ultrafiltration Systems work?

A: Microfiltration & Ultrafiltration Systems employ porous membranes with incredibly small pore sizes to separate particles and impurities from liquids. As the liquid passes through these membranes under pressure, solids and contaminants are retained, resulting in clarified and purified liquid output.

Q: What are the key benefits of using Microfiltration & Ultrafiltration Systems?

A: Utilizing these Systems offers numerous advantages, including improved water quality, reduced wastewater disposal costs, enhanced resource recovery, minimal environmental impact, and versatile applications in various industries.

Q: In which industries are Microfiltration & Ultrafiltration Systems commonly used?

A: Microfiltration & Ultrafiltration Systems find applications across a wide range of industries, including water treatment, food and beverage, pharmaceuticals, chemical manufacturing, and more. Their versatility and efficiency make them valuable tools in processes requiring precise filtration and separation.