Flame Arrestor

Our highly-engineered custom sintered porous metal assemblies are a popular choice for flame arrestors because they allow precise gas flow control while providing a mechanically sound media to quench the flame front. Sintered porous metal flame arrestors offer a cost-effective solution for high-volume devices, especially for applications that require the prevention of a flame during an intense explosion event. Our flame arrestor solutions are compliant with ATEX, FM, UL, CSA, and other standards and directives.

Questions? Call 860.747.6333 Today!

Literature & Data Sheets

Typical Applications

- Production processes and gas lines using combustible gases

- Gas analyzers in combustible atmospheres

- Acetylene gas welding torches

Flame Arrestors

Overview of Mott products for flame arresting applications.

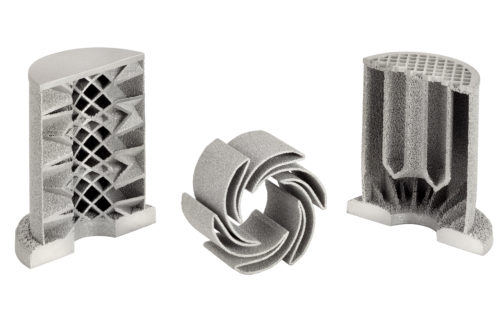

Additive Manufacturing

Our additive manufacturing capabilities provide the most uniform porosity and unique geometries for your application.

Explore Mott’s Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Industrial Flow Restrictors

Overview of Mott flow control using porous metal technology

Porous Metal Overview

Check out the features and benefits of Mott sintered porous metal media that delivers uniform porosity for superb filtration efficiency and structural integrity.

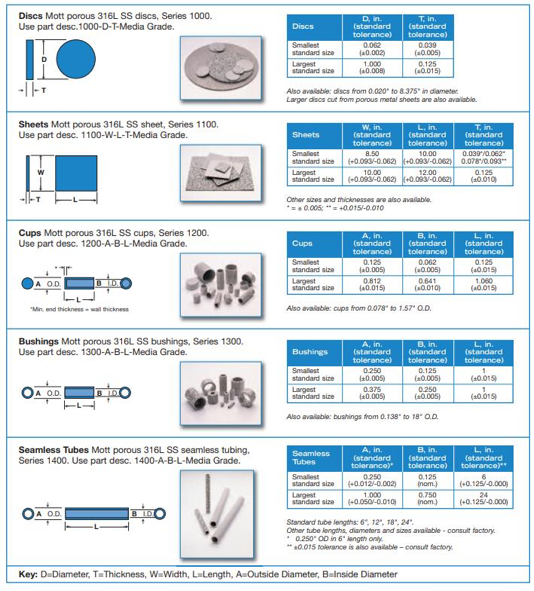

Product Specs

| Dimensions |

Standard Dimensions, custom options available consult factory

|

|---|---|

| Material Choices |

Standard filter and hardware alloys – 316L SS, 310 SS, Titanium, Inconel 600, Hastelloy® C-276, Hastelloy® X, Monel® 400, Nickel 200 Other alloys are available, consult factory |

| Hardware Options |

Extension hardware and fitting options available for full assembly – Standard tubing, End-fittings like compression, NPT, or VCR® Custom hardware options available, consult factory |

| Media Grades |

Nominal pore sizes available – 0.2, 0.5, 2, 5, 10, 20, 40, 100 Custom options available, consult factory |

| Performance Testing |

Lab validation tests available. Ask a Mott representative about using our Customer Innovation Center to support your next project. |

Videos & Articles

Our Design Capabilities

From component level to full Flame Arrestor assemblies, we can design and manufacture complete solutions in flame arresting.

- Diverse Hardware Options

- Additive Manufacturing Capabilities

Relevant Services

Design Expertise – From start to finish, we customize solutions based on your design parameters – challenge us!

Engineering and Qualification Validation Support – If you need help beyond the component level, we also work on systems and test procedures to help you get qualified and approved. Let us know how we can help.

Fluid Modeling – Our extensive applications have built a library of data to increase the accuracy of our flow models to provide initial performance and feasibility estimates prior to building prototypes.

Extensive Partner Network – If a material is not listed or capability not in-house, we maintain an extensive network of partners for new material procurement, advanced manufacturing capabilities, and validation testing.

What are flame arrestors?

Flame arrestors, a critical component in industrial safety, are devices designed to prevent the propagation of flames and explosions in hazardous environments. Mott’s flame arrestors, crafted from advanced porous metal technology, act as indispensable safeguards in applications where the presence of flammable gases or vapors poses a threat. By strategically placing Mott’s flame arrestors in equipment such as gas detectors, welding torches, and storage tanks, you can effectively mitigate the risk of catastrophic incidents. These flame arrestors ensure that any potential flame front is quelled, maintaining a secure work environment and adhering to industry standards for safety and compliance.

FAQs: Flame Arrestors

Q: What are flame arrestors?

A: Flame arrestors are safety devices designed to prevent the propagation of flames and explosions in environments where flammable gases or vapors are present. They are crucial for safeguarding industrial processes and preventing potentially catastrophic incidents.

Q: How do Mott flame arrestors work?

A: Mott flame arrestors utilize porous metal technology to interrupt and extinguish flame fronts. The porous structure allows gas to pass through while simultaneously cooling and extinguishing any flames, making them a highly effective safety measure.

Q: Where are Mott flame arrestors used?

A: Mott flame arrestors find applications in various industries, including petrochemical, oil and gas, pharmaceuticals, and manufacturing. They are commonly employed in equipment such as gas detectors, storage tanks, and welding torches.

Q: Why choose Mott flame arrestors?

A: Mott flame arrestors are preferred due to their advanced porous metal technology, which ensures reliable flame quenching. They also offer a wide range of alloys for chemical compatibility and are compliant with industry standards like TEX, FM, UL, and CSA, making them a trusted choice for safety and compliance.