Injection Molding

Porous products are essential in the injection molding process, utilized specifically to vent gases during manufacturing, thus protecting products from defects. In the realm of injection molding, Mott porous products have been a key component in mold vent applications, serving a diverse range of industries including plastic, rubber, and metal molders for over six decades. By efficiently venting molds in the injection molding process, manufacturers can effectively avoid the adverse effects of entrapped or evolved gases, which are typically caused by heated air in the mold, steam generation from water in binders, and combustion from binders and coatings.

Questions? Call 860.747.6333 Today!

Related Resources

Typical Applications:

- Injection Molding

- Material Handling

Porous Metal Overview

Check out the features and benefits of Mott sintered porous metal media that delivers uniform porosity for superb filtration efficiency and structural integrity.

Lab & Engineering Services

Discover our entire range of services, including rapid prototyping, filter feasibility, media characterization and more.

Explore Mott's Capabilities

Provides an overview of markets served, applications, products, materials, and engineering capabilities.

Understanding Injection Molding with Mott Porous Products

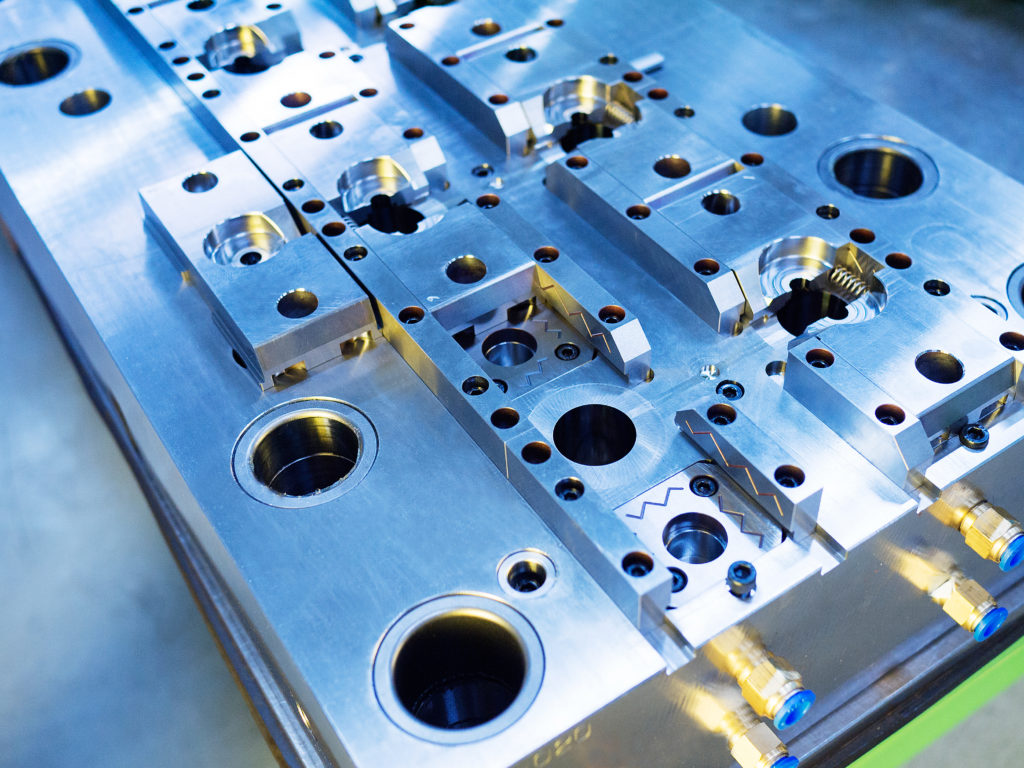

Injection molding is a widely used manufacturing process for creating plastic, rubber, and metal items, where materials are heated and injected into molds. Mott’s porous products play a crucial role in this process. These innovative products are designed to naturally vent gases during the injection molding process, preventing defects like air pockets and inconsistencies in the final product. With over 60 years of expertise, Mott’s solutions ensure a smoother, more reliable injection molding operation, safeguarding the quality and integrity of the molded products. Their technology is particularly valuable in high-precision applications where the slightest imperfection can lead to product failure.

FAQs: Injection Molding with Mott's Contribution

Q: What is Injection Molding?

A: Injection molding is a manufacturing technique for producing items by injecting molten material into a mold, commonly used for mass-producing plastic, rubber, and metal components with high precision.

Q: How do Mott’s porous products enhance the Injection Molding process?

A: Mott’s porous products are designed to vent gases during the injection molding process, thereby preventing defects such as air pockets and surface blemishes in the final product. This ensures higher quality and consistency in the molded items.

Q: What materials are typically used in Injection Molding?

A: Thermoplastic and thermosetting polymers, metals (in Metal Injection Molding), and specialized materials like glass or silicone are used depending on the application.

Q: What are the benefits of using Injection Molding?

A: Injection molding offers high production rates, precise control over product dimensions, efficient use of materials, and the ability to produce complex shapes with minimal finishing work.