Filter Assemblies and Porous Components

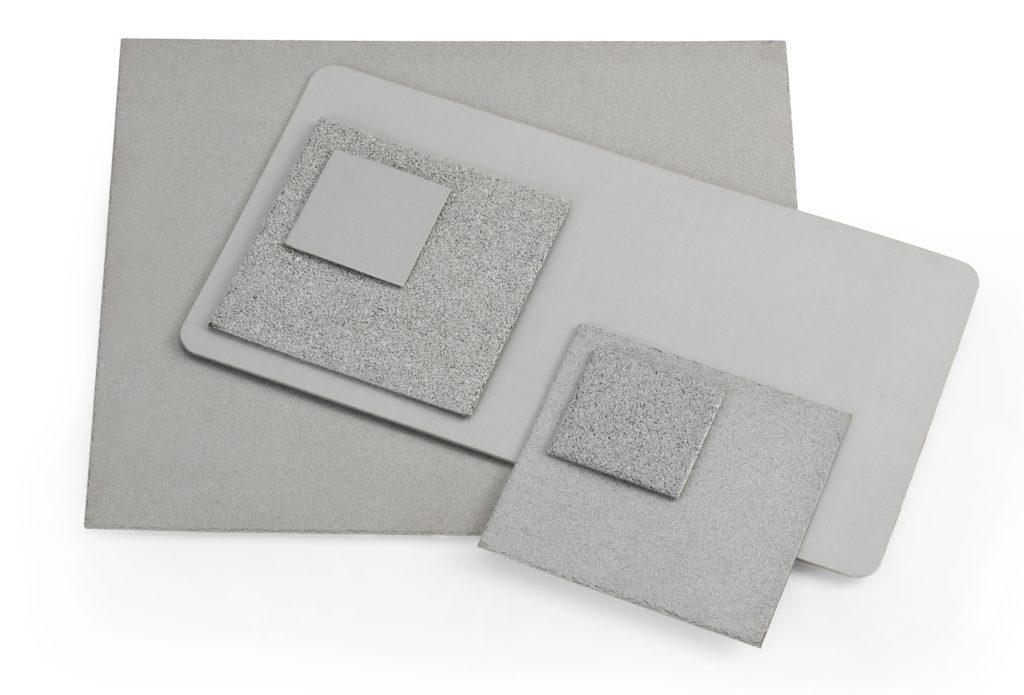

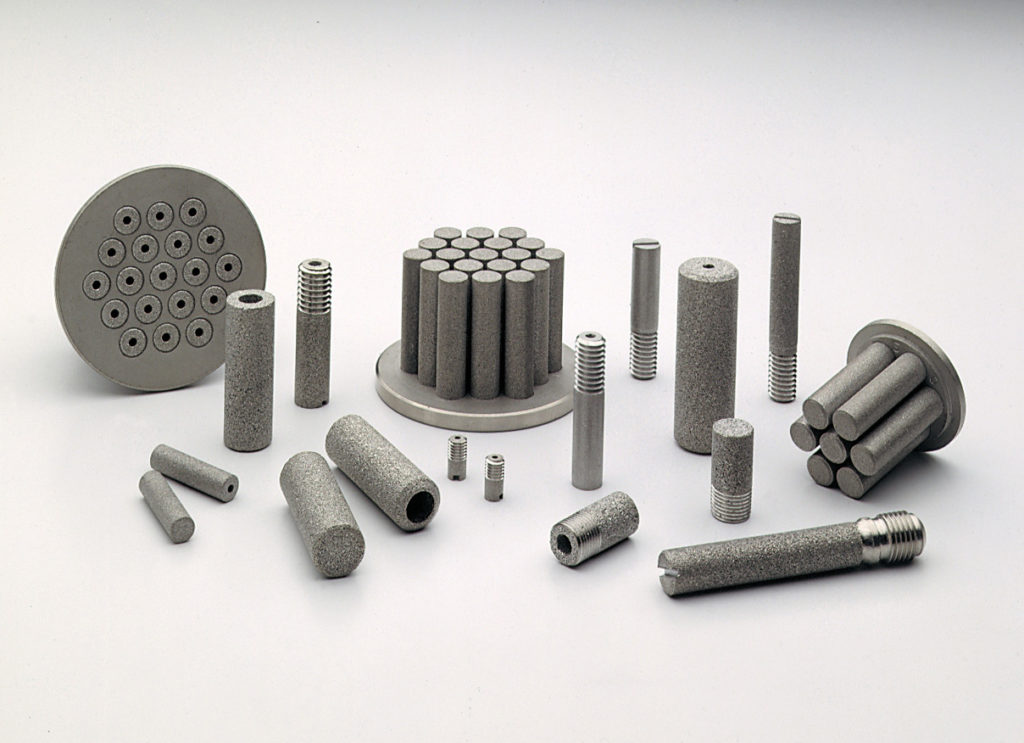

Mott excels in the fabrication of OEM porous metal parts, particularly sintered metal filters, which encompass bushings, cups, discs, sheet, and tubes. The structural integrity of the sintered metal filter, combined with the inherent properties of metal and the diverse levels of porosity, empowers our engineering teams to craft products that can endure high temperatures, elevated pressures, and corrosive operating conditions.

- Process Filters, Skids and Elements

- Water Reclamation System

- Industrial Filter Cartridges

- High Purity Filters & Components

- Filter Assemblies and Porous Components

- Frit Assemblies and Lab Filters

- Industrial Gas Flow Restrictors

- Industrial Sparger Systems

- Gas Diffusion & Transport Layers

- Flame Arrestor Products

- Sintered Porous Wicks

- 3D Printed Products

- Fluid Process Equipment

- Thermal Management Heat Pipe

- Fluidizers & Snubbers

About Sintered Metal Filter Assemblies & Components

Mott Corporation stands at the forefront of designing and manufacturing sintered metal filter assemblies and components. These state-of-the-art products offer unparalleled precision filtration and fluid management solutions across various industries. With a unique blend of structural integrity and adaptable porosity levels, Mott’s sintered metal filters ensure optimal protection and performance in diverse operating conditions, from high temperatures and pressures to corrosive environments. Dive deeper to understand the versatility and applications of these advanced filtration systems.

FAQs: Sintered Metal Filters

Q: How does Mott Corporation stand out in the sintered metal filter industry?

A: Mott Corporation is a recognized leader in the sintered metal filter industry, known for its advanced engineering and manufacturing capabilities. With decades of experience, Mott consistently delivers high-quality filters that meet the specific needs of various industries, ensuring precision filtration and optimal performance.

Q: What makes Mott’s sintered metal filters unique?

A: Mott’s sintered metal filters are crafted using proprietary techniques that ensure consistent pore sizes and unparalleled structural integrity. Additionally, Mott offers customization options, allowing clients to specify porosity, material, and design, ensuring the filter perfectly aligns with their application requirements.

Q: Can I get a custom sintered metal filter design from Mott?

A: Absolutely! Mott Corporation prides itself on its ability to work closely with clients to design and manufacture custom sintered metal filters tailored to specific applications and operational conditions. Their engineering team collaborates with customers to ensure every filter meets the desired specifications and performance criteria.

Q: How does Mott ensure the quality and durability of its sintered metal filters?

A: Mott Corporation employs rigorous quality control measures throughout the manufacturing process. From material selection to the final sintering process, every step is monitored to ensure the filters meet the highest standards of quality, durability, and performance.