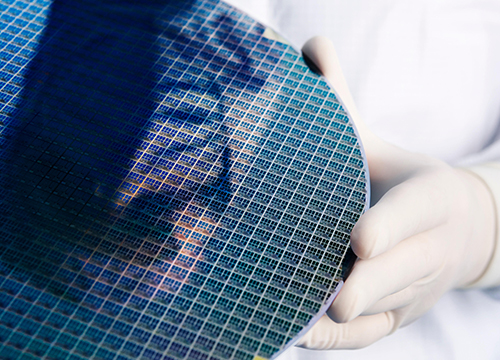

Shaping the Future of Semiconductor Manufacturing with Mott's Expertise

Mott Corporation is a trusted partner in the realm of microelectronic engineering, providing solutions that drive efficiency and precision in semiconductor manufacturing. Our high-purity porous products ensure 9-log filtration of particles, maximizing wafer yield and enhancing semiconductor tool performance. From bulk gas delivery systems that ensure particle-free gas to advanced components for fab facilities, our offerings are designed for the highest standards of the microelectronics industry. Dive into Mott's suite of microelectronic engineering solutions and discover how we're shaping the future of semiconductor manufacturing.