Setting New Standards in Custom Manufacturing with Mott

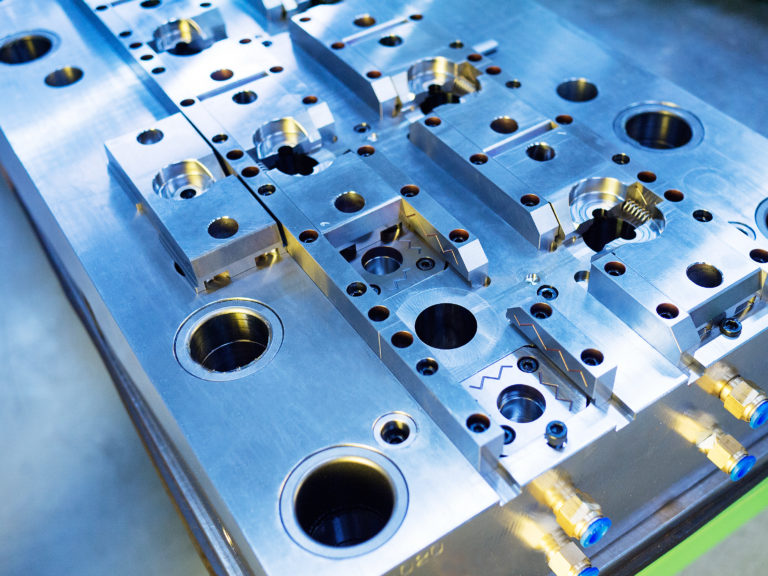

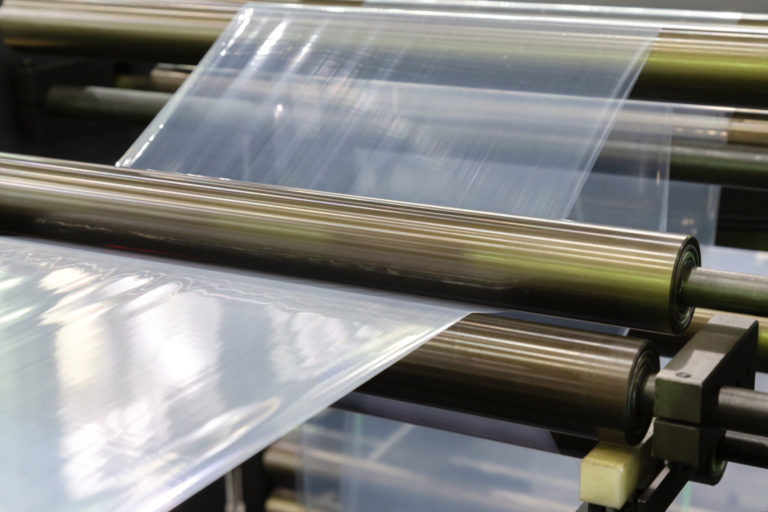

Mott Corporation stands at the forefront of custom manufacturing equipment, offering tailored solutions for a range of applications. Our porous products enhance mold vent applications in injection molding, ensuring optimal performance. In material handling, we ensure smooth transport of sensitive materials for high-yield production. Our expertise extends to designing in-line piping filters, valve, regulator, and flow control components, integrating filtration for longevity and precision.